C55 polypropylene fiber concrete, applications thereof, and preparation method of U-shaped beam

A polypropylene fiber and concrete technology, applied in the field of concrete, can solve problems such as structural bearing capacity, cracks and adverse effects on durability, insufficient compressive strength of concrete, and prestress that cannot meet construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

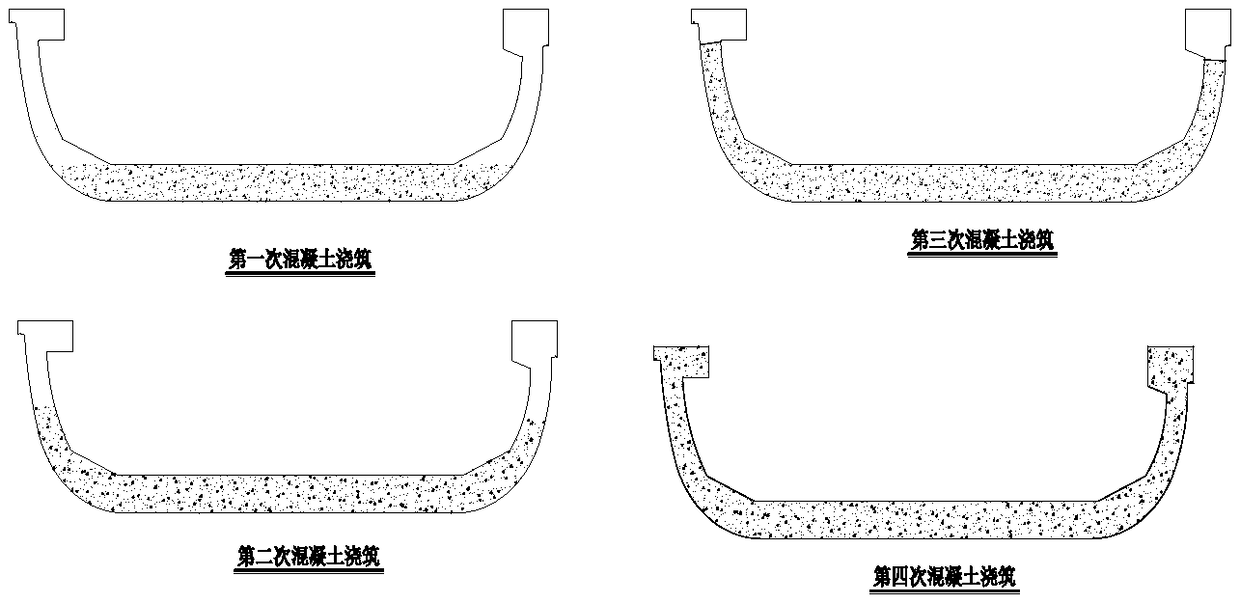

[0038] The present invention also provides a method for preparing a U-shaped beam, which adopts the C55 polypropylene fiber concrete described in the above technical scheme, and includes the following steps:

[0039] Pouring the C55 polypropylene fiber concrete into the steel formwork of the U-shaped beam to obtain a U-shaped beam preform;

[0040] The U-shaped beam preform is subjected to steam curing and natural curing in sequence to obtain a U-shaped beam.

[0041] In the present invention, the C55 polypropylene fiber concrete is poured into the steel formwork of the U-shaped beam to obtain a U-shaped beam preform.

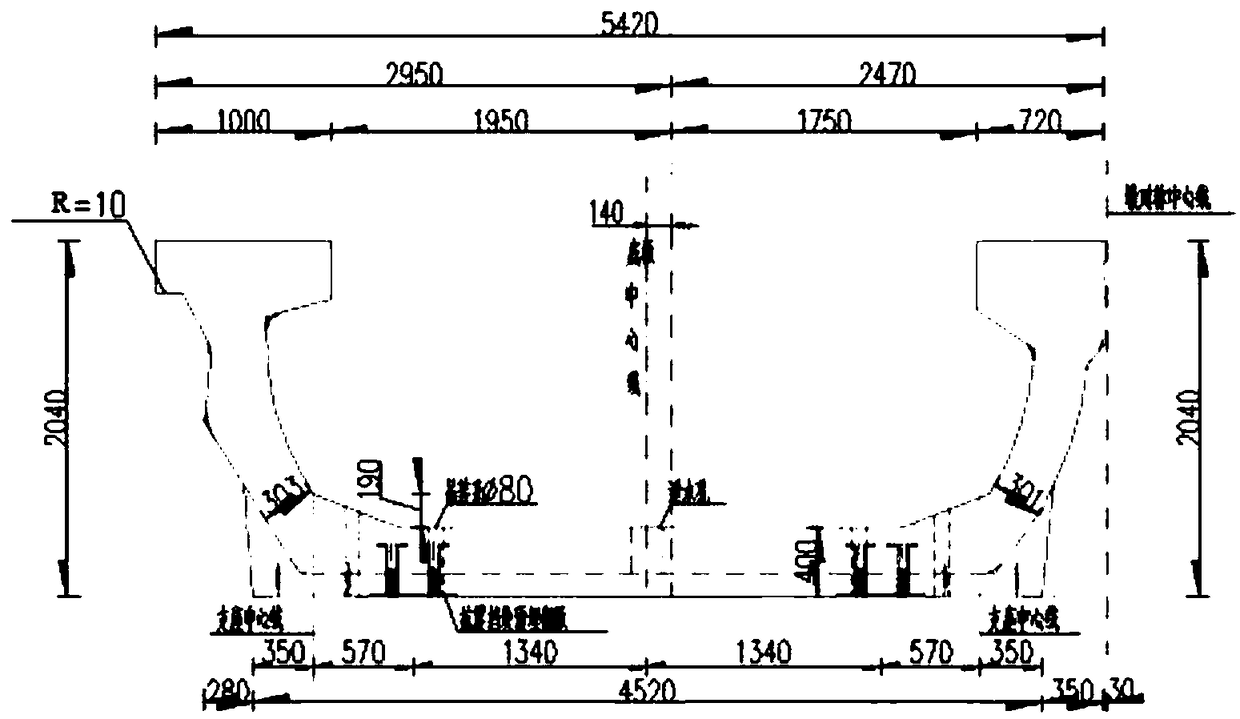

[0042] figure 1 It is a schematic diagram of the structure of the U-shaped beam of the present invention. The web thickness of the U-shaped beam is preferably 400 mm, the width is preferably 4520 mm, and the beam wall thickness is preferably 301 mm.

[0043] In the present invention, the steel formwork has sufficient strength and rigidity to meet the requirements of cons...

Embodiment 1

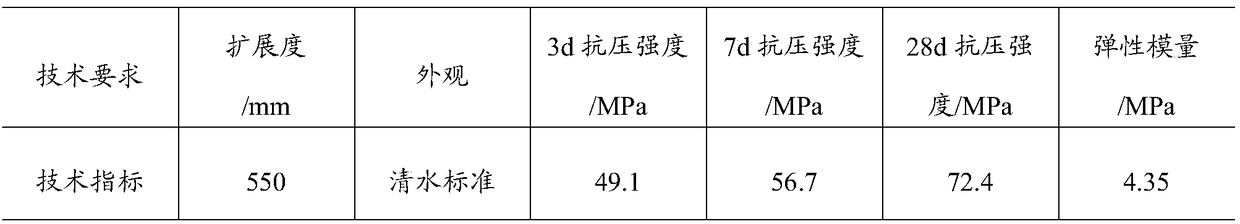

[0061] Each cubic meter of C55 polypropylene fiber concrete contains: cement (P.O52.5 cement from Qingdao Branch of Shandong Shanshui Cement Group Co., Ltd., the fineness of cement is 350m 3 / kg, 3d compressive strength of 32.5MPa, 28d compressive strength of 56.8MPa) 408kg, C55 polypropylene fiber (12mm, Tai'an Yuanshun Building Materials Co., Ltd.) 0.9kg, mineral powder (Qingdao Zhongkuang Hongyuan Industry and Trade Co., Ltd.) Co., Ltd.’s commercially available S95 ore powder, 7d activity is 78%, 28d activity is 102%) 46kg, fly ash (Class F class I fly ash marketed by Huadian Laizhou Power Generation Co., Ltd.) 56kg, coarse aggregate ( The crushed stones have two sizes of 5-10mm and 10-20mm. The crushed values of 5-10mm and 10-20mm crushed stones are 5.8 and 5.3, respectively, and the mud content is 0.7% and 0.6%, respectively. The mud content is 0.2% and 0.3%, respectively. Mo Daxin Crushing Site, the proportion of the gravel with a particle size of 5-10mm and 10-20mm is 2...

Embodiment 2

[0073] Same as Example 1, except that the mass ratio of cement, mineral powder, fly ash, fine aggregate, coarse aggregate and polycarboxylic acid water reducing agent in C55 polypropylene fiber concrete is 1:0.16:0.20:1.55: 2.4:0.017, the water-cement ratio is 0.22, the parameter of C55 polypropylene fiber is 0.9kg / m 3 .

[0074] The performance of the C55 polypropylene fiber concrete prepared in Example 2 was tested. The expansion degree of the C55 polypropylene fiber concrete was 510 mm, and other properties were similar to those in Example 1.

[0075] Take the C55 polypropylene fiber concrete of Example 2 to prepare U-shaped beams. The preparation method is the same as that of Example 1. The difference is that steam curing includes static stop (room temperature, 12h), heating (rate 15℃ / h, when the outdoor average When the temperature is lower than 10℃, the initial heating rate of heating is 5℃ / h), constant temperature (50℃, 21h) and cooling (rate 25℃ / h), the performance test of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com