Preparation method and application for patterned two-dimensional conjugate microporous polymer

A microporous polymer and two-dimensional conjugation technology, applied in the field of polymer semiconductor materials, can solve the problems of mold shrinkage deformation, expensive, film damage, etc., and achieve the effect of mild reaction conditions, easy industrial application, and easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of poly 9,9'-biscarbazole (Material I)

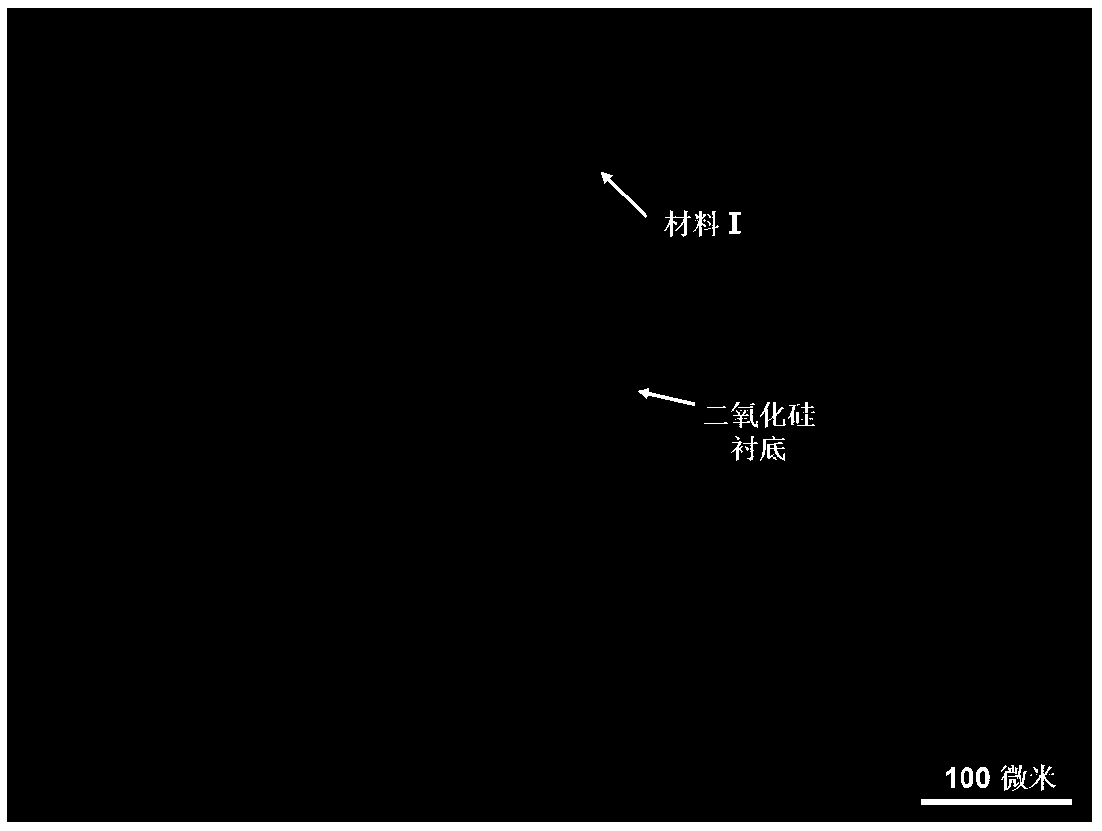

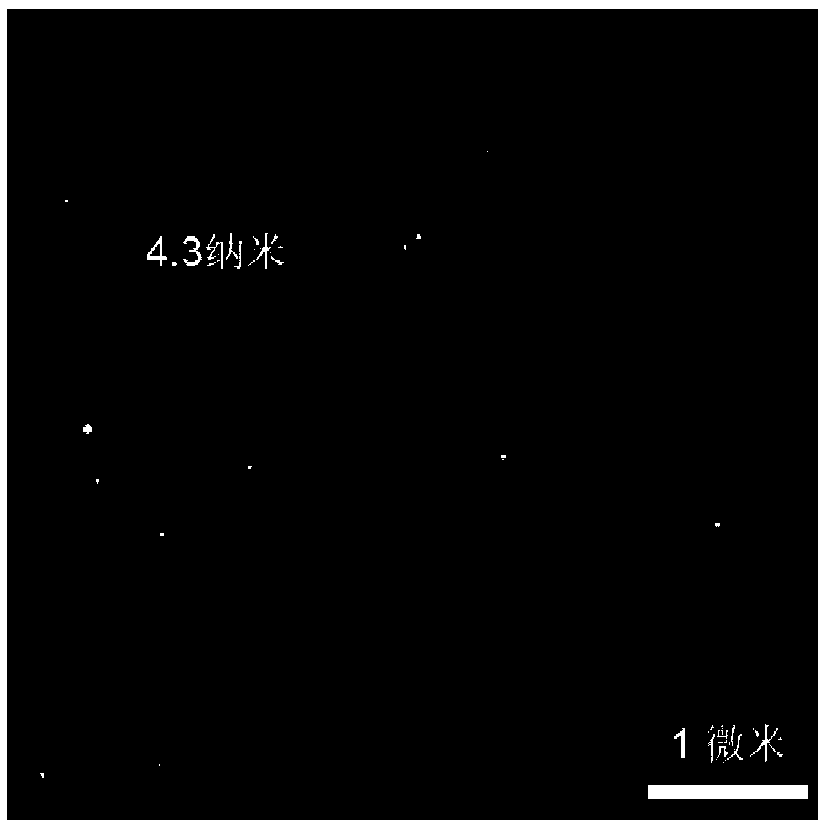

[0055] A schematic diagram of the polymerization process is shown in figure 1 As shown, the specific steps are as follows: the chlorobenzene solution of 10mg / mL 9,9'-biscarbazole is spin-coated on a clean silicon dioxide (300 nm) / silicon wafer substrate, and the spin-coating condition is 4000 rpm minutes, 20 seconds. The monomer-spin-coated substrate was then dried in an oven at 120 °C for 30 minutes, and the mask was placed on the monomer-spin-coated substrate. Then, under the condition of 25°C, place the substrate under the light source, take it out after reacting for 1 hour, then remove the mask plate, and wash the sample repeatedly with dichloromethane and ethanol in sequence. After drying in an oven at 50 °C, a large-area, patterned ultrathin poly-9,9'-biscarbazole film grown on the substrate was obtained. It was found by optical microscopy that patterned two-dimensional conjugated microporous polymers ( fig...

Embodiment 2

[0057] Preparation of poly 4,4'-bis(N-carbazole)-1,1'-biphenyl (material Ⅲ)

[0058] Spin-coat a 10 mg / mL solution of 4,4'-bis(N-carbazole)-1,1'-biphenyl in chlorobenzene on a clean silica (300 nm) / silicon wafer substrate, spin-coat The conditions are 4000 rpm, 20 seconds. The monomer-spin-coated substrate was then dried in an oven at 120° C. for 30 minutes, and a mask was placed on the substrate. Then, under the condition of 25°C, place the substrate under the light source, take it out after reacting for 1 hour, then remove the mask plate, and wash the sample repeatedly with dichloromethane and ethanol in sequence. After drying in an oven at 50°C, a large-area, patterned ultrathin poly 4,4'-bis(N-carbazole)-1,1'-biphenyl film grown on the substrate was obtained.

[0059] The prepared materials were photographed, and it can be seen from the figure that we can prepare two-dimensional conjugated microporous polymers with different patterns by using different masks, including c...

Embodiment 3

[0065] Preparation of poly 4,4'-bis(N-carbazole)thiophene (Material Ⅳ)

[0066] Spin-coat a 10 mg / mL chlorobenzene solution of 4,4'-bis(N-carbazole)thiophene on a clean silica (300 nm) / silicon wafer substrate at 4000 rpm, 20 seconds. The monomer-spin-coated substrate was then dried in an oven at 120°C for 30 minutes, and a mask was placed on the substrate. Then, under the condition of 25°C, place the substrate under the light source, take it out after reacting for 1 hour, then remove the mask plate, and wash the sample repeatedly with dichloromethane and ethanol successively. After drying in an oven at 50 °C, large-area, patterned ultrathin poly-4,4'-bis(N-carbazole)thiophene films grown on substrates were obtained. It was found by optical microscopy that patterned two-dimensional conjugated microporous polymers ( Figure 11 ). The thickness of the obtained polymer film measured by atomic force microscope is about 3.7 nanometers ( Figure 12 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com