Encapsulating material of new energy automobile battery and preparation method thereof

A technology for new energy vehicles and potting materials, applied in the field of new energy vehicle battery potting materials and their preparation, can solve problems such as thermal conductivity and mechanical strength to be improved, achieve excellent mechanical properties and thermal conductivity, and reduce fire and explosion. , the effect of excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

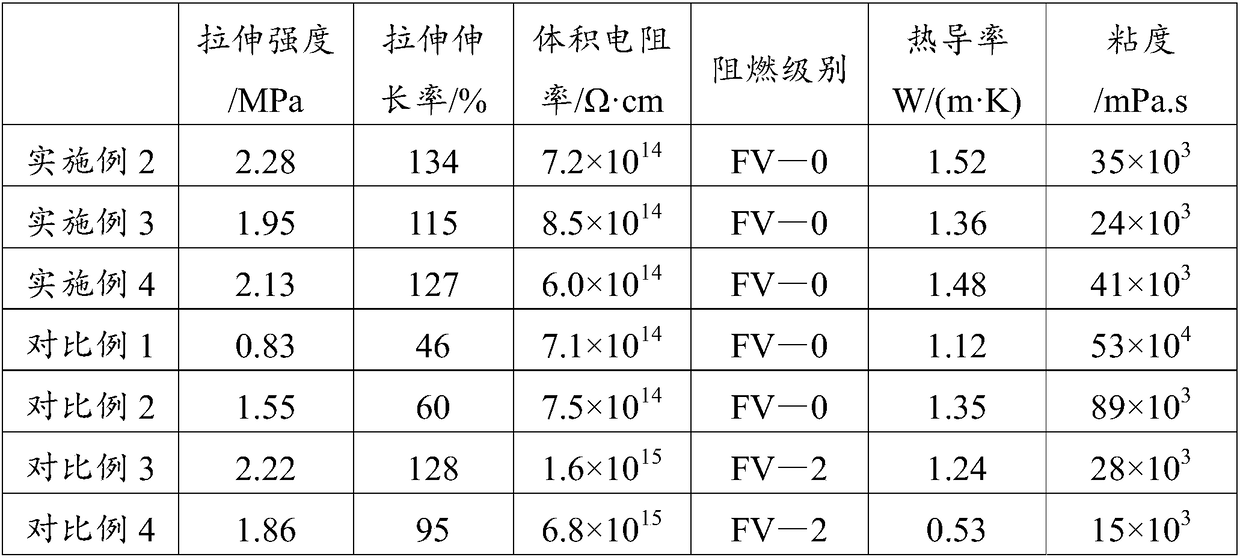

Examples

Embodiment 1

[0029] This example 1 provides a preparation method of hexadecyltrimethoxysilane modified alumina, which includes the following steps: put the alumina with a particle size of 5-15 μm in an electrothermal constant-temperature blast drying oven, and dry it at 105 It was dried at ℃ for 3 hours, and then poured into a high-speed mixer with a rotation speed of 1500r / min. Dilute hexadecyltrimethoxysilane with a mixed solvent of isopropanol and toluene to a concentration of 20%, spray it into the above-mentioned high-speed mixer under stirring, raise the temperature to 110°C, and continue stirring for 30 minutes. Bake for 4 hours, seal and store for later use to obtain the hexadecyltrimethoxysilane-modified alumina. The dosage ratio of the isopropanol and toluene is 1:1; the dosage of the cetyltrimethoxysilane is 1.5% of the mass of alumina.

Embodiment 2

[0031] This embodiment 2 provides a new energy vehicle battery potting material, which includes the following components by weight: 100 parts of vinyl-terminated silicone oil, 4 parts of hydrogen-containing silicone oil, 200 parts of cetyltrimethoxysilane modified alumina 0.1 part of platinum catalyst, 35 parts of aluminum diethylphosphinate, 4 parts of fumed silica, 0.8 part of hexamethyldisilazane, 3 parts of peroxide curing agent and dibutyl phthalate 1.5 servings. In terms of mass percentage, the peroxide vulcanizing agent is composed of 25% dibenzoyl peroxide and 75% bis-tert-butylperoxycumene.

[0032] The preparation method of described new energy vehicle battery potting material, it comprises the steps:

[0033] (1) Base material: Add vinyl-terminated silicone oil, hexamethyldisilazane and fumed silica into a kneader, knead for 2.5 hours, add 125g of distilled water, knead for 12 minutes, heat up to 160°C, Dehydration under MPa conditions for 0.8h to obtain the base ...

Embodiment 3

[0038]This embodiment 3 provides a new energy vehicle battery potting material, which includes the following components by weight: 100 parts of vinyl-terminated silicone oil, 2 parts of hydrogen-containing silicone oil, 150 parts of hexadecyltrimethoxysilane modified alumina 0.05 parts of platinum catalyst, 20 parts of aluminum diethylphosphinate, 2 parts of fumed silica, 0.5 parts of hexamethyldisilazane, 1 part of peroxide curing agent and dibutyl phthalate 0.5 servings. In terms of mass percentage, the peroxide vulcanizing agent is composed of 15% dibenzoyl peroxide and 85% bis-tert-butylperoxycumene.

[0039] The preparation method of described new energy vehicle battery potting material, it comprises the steps:

[0040] (1) Base material: Add vinyl-terminated silicone oil, hexamethyldisilazane and fumed silica into a kneader, knead for 2 hours, add 50g of distilled water, knead for 10 minutes, heat up to 150°C, and then knead at a vacuum of 0.1MPa Dehydration under cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com