Detection method of food processing machine wall breaking rate

A food processing machine and detection method technology, applied in the direction of volume measuring instrument/method, measuring device, measuring capacity, etc., can solve the problems of inability to calculate the number of unbroken soybean cells, separation, and inability to calculate the broken wall rate, etc., to achieve artificial The effects of small factors, wide application range, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

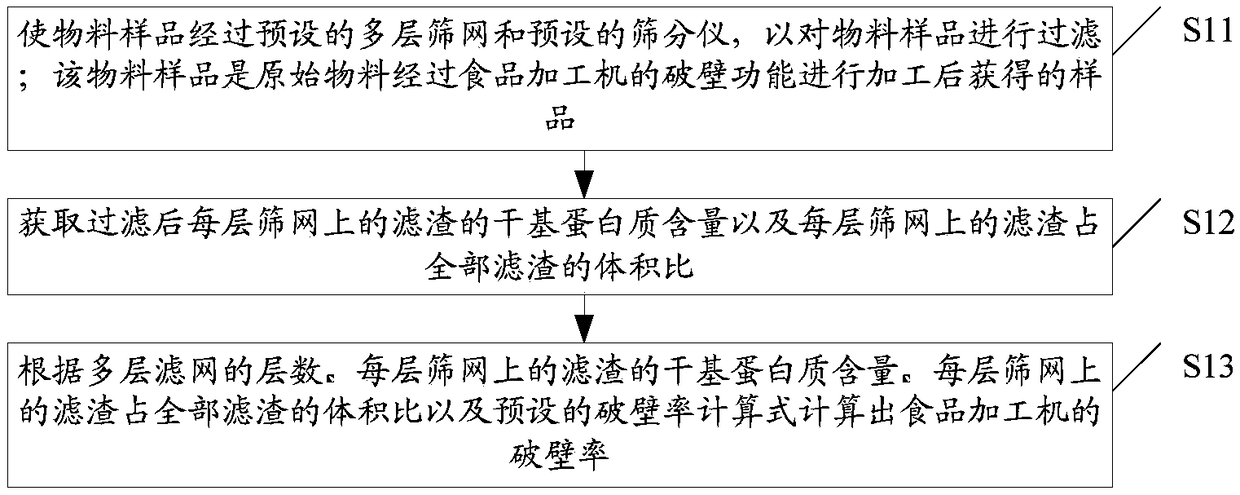

[0041] A method for detecting the wall breaking rate of a food processor, such as figure 1 As shown, the method may include steps S11-S13:

[0042] S11. Let the material sample pass through the preset multi-layer screen and the preset sieving apparatus to filter the material sample; the material sample is a sample obtained after the original material is processed by the wall-breaking function of the food processor.

[0043] In the embodiment of the present invention, prior to testing, a certain quality of raw material can be selected and processed in a food processor with a preset wall-breaking function to obtain processed slurry as a material sample to be tested. For example, a soy milk sample can be used as an example to illustrate: You can weigh a certain mass of dry soybeans, add water to the scale line, and prepare a soy milk sample according to the instructions of the broken wall soymilk machine.

[0044] In the embodiment of the present invention, 80g of dry soybeans can...

Embodiment 2

[0081] In this embodiment, the selection of the screen is further optimized on the basis of the first embodiment.

[0082] Optionally, the method may further include: rejecting, from the selected multiple screens, screens whose volume ratio of the filter residue on the screen to the total filter residue is less than or equal to a preset ratio threshold. That is, the volume ratio of the selected filter residue on each screen to the total filter residue is greater than the preset ratio threshold.

[0083] In the embodiment of the present invention, the ratio threshold can be determined according to different application scenarios, such as different materials and different calculation accuracy requirements, and there is no limitation on its specific value.

[0084] In the embodiment of the present invention, the aforementioned soymilk sample embodiment can still be used as an example for illustration: in the foregoing content, 50 mesh, 80 mesh, 120 mesh, 150 mesh, 180 mesh, and 2...

Embodiment 3

[0093] This embodiment further expands the original material to be tested on the basis of any of the above embodiments.

[0094] Optionally, the original material may include: a single food material or a mixed food material; wherein, the difference in the average cell diameter of each food material in the mixed food material is smaller than a preset second difference threshold.

[0095] In the embodiment of the present invention, in the above-mentioned test method embodiment, soybeans (or soybeans) are selected as the experimental material. Machine finished pulping food material), such as single food material such as sesame, rice, millet, peanut or its mixed food material also has applicability. In specific implementation, the test of the wall breaking rate can be completed by adjusting the sieve with the corresponding pore size according to the average particle size of the food material cells for filtration. Among them, if it is a mixture of ingredients, you should choose in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com