Preparation method for aqueous anode slurry containing VGCF (vapor-grown carbon nanoflbers) of lithium ion battery

A lithium-ion battery, cathode slurry technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of easy agglomeration during solvent dispersion, large specific surface of VGCF, and uniform dispersion of various components. Good performance, low cost, and the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

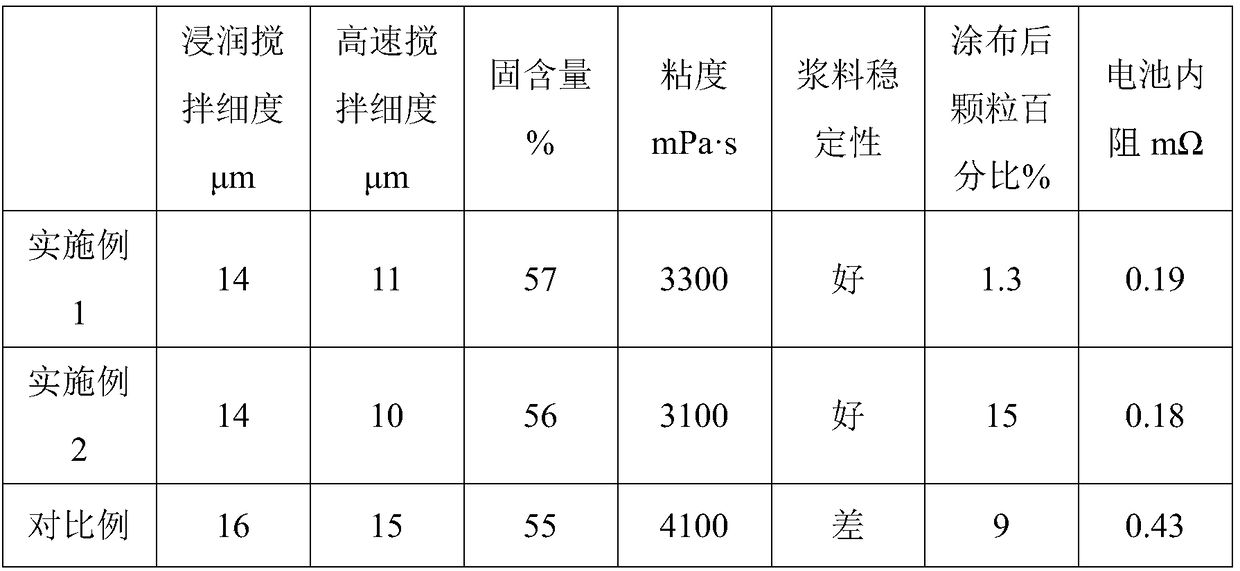

Examples

Embodiment 1

[0023] 1. First, mix 1228g LA132 (solid content is 15wt%) and 724g water as a solvent, put it into a double-star mixer and stir for 15min at a revolution speed of 20rpm / min and a dispersion speed of 3000rpm / min; measure its viscosity to be 3100mPa·s.

[0024] 2. Next, add 26.3g SP into the above solution; then stir for 50min at a revolution speed of 10rpm / min and a dispersion speed of 1000rpm / min; measure its fineness to be less than 15μm. After the fineness is lower than 15 μm, add 877.2g VGCF composite slurry (solid content is 6wt%) into the above mixed solution, and then stir at a high speed of 40rpm / min at a revolution speed of 4500rpm / min for 100min; The content is 67%.

[0025] 3. Then add 5000g of lithium iron phosphate powder into the above solution for two-stage stirring; first stir at a revolution speed of 10rpm / min and a dispersion speed of 1000rpm / min for 10min to achieve the effect of infiltration, and then at a revolution speed of 40rpm / min, disperse Stir at a s...

Embodiment 2

[0028] 1. First, mix 1430g LA132 and 576g water as a solvent, put it into a double star mixer and stir for 15min at a revolution speed of 20rpm / min and a dispersion speed of 3000rpm / min; the viscosity is measured to be 3100mPa·s.

[0029] 2. Next, add 80g of SP into the above solution; stir for 50min at a revolution speed of 10rpm / min and a dispersion speed of 1000rpm / min; measure its fineness to be less than 15μm. Add 1166.6g of VGCF composite slurry (6wt% solid content) into the above mixed solution, and then stir at high speed for 100min at a revolution speed of 40rpm / min and a dispersion speed of 4500rpm / min; the solid content of this stage is 65%.

[0030] 3. Then add 5000g of lithium iron phosphate powder into the above solution for two-stage stirring; first stir at a revolution speed of 10rpm / min and a dispersion speed of 1000rpm / min for 10min to achieve the effect of infiltration, and then at a revolution speed of 40rpm / min, disperse Stir at a speed of 4500rpm / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com