Method and device for preparing honeycomb sandwich structure with microperforated face plate, and such structure

A sandwich structure and micro-perforation technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem of high cost, and achieve the effect of avoiding high cost and time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

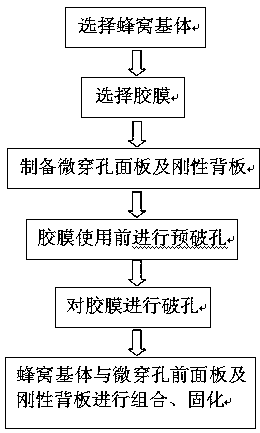

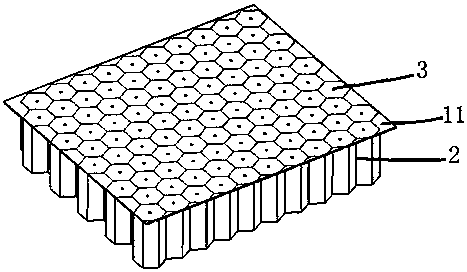

[0023] Such as figure 1 A preparation method of a sandwich structure containing a micro-perforated panel is shown, comprising the following steps:

[0024] 1) Select the honeycomb substrate: the honeycomb substrate is selected from aramid paper honeycomb, glass cloth honeycomb, aluminum honeycomb or plant fiber honeycomb, the depth of the honeycomb is h=5mm~500mm, and the side length of the honeycomb unit is L=2mm~8mm;

[0025] 2) Select the film: the film can be epoxy film, double horse film or polyimide film, the thickness of the film is t=0.02mm-0.15mm;

[0026] 3) Preparation of micro-perforated panel and rigid backplane: select or prepare a 0.2mm-10mm thick panel and a rigid backplane, and process the panel into a micro-perforated panel by laser drilling or mechanical drilling, with a microhole diameter of 0.1 mm-3mm, perforation rate 2%-20%;

[0027] 4) Prepare a special needle roller: the needles in the needle roller are arranged in a regular triangle, the distance be...

Embodiment 1

[0034] 1) Select the honeycomb matrix: select NH-5.5-48 produced by AVIC Composite Materials, a piece of aramid paper honeycomb core with a height of 40mm, and set aside.

[0035] 2) Select the adhesive film: choose the J-116 epoxy adhesive film produced by Heilongjiang Petrochemical Research Institute, the thickness of the adhesive film is t=0.4mm;

[0036] 3) Preparation of micro-perforated panel and rigid back panel: select two 0.5mm thick glass steel plates, one of which is used as a rigid back panel, and the other is processed into a micro-perforated panel by mechanical drilling, with a perforation rate of 5% and a hole diameter of 1.0mm;

[0037] 4) Prepare a special needle roller: the needles in the needle roller are arranged in an equilateral triangle, the distance between the needles is 9.526mm, the needle diameter is 0.2mm, and the length is 15mm;

[0038] 5) Film perforation: Use a needle roller to pre-perforate the film, and then lay the film on the honeycomb. When...

Embodiment 2

[0041] 1) Select the honeycomb matrix: select NRH-5-48 produced by AVIC Composite Materials, a piece of aramid paper honeycomb core with a height of 20mm, and set aside.

[0042] 2) Select the adhesive film: choose the J-154 epoxy adhesive film produced by Heilongjiang Petrochemical Research Institute, the thickness of the adhesive film is t=0.3mm;

[0043] 3) Preparation of micro-perforated panel and rigid back panel: select two 1.0mm thick glass steel plates, one of which is used as a rigid back panel, and the other is machined into a micro-perforated panel with a perforation rate of 5% and a hole diameter of 1.0mm;

[0044] 4) Prepare a special needle roller: the needles in the needle roller are arranged in an equilateral triangle, the distance between the needles is 8.66mm, the needle diameter is 0.2mm, and the length is 15mm;

[0045] 5) Film perforation: Use a needle roller to pre-perforate the film, and then lay the film on the honeycomb. When laying, try to make the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com