Formaldehyde removing agent

A technology of aldehyde remover and glycine, which is applied in the direction of gas treatment, membrane technology, and separation of dispersed particles, can solve the problems of damage to wood and loss of efficacy, and achieve the effect of enhanced moisturizing performance, strong capture ability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

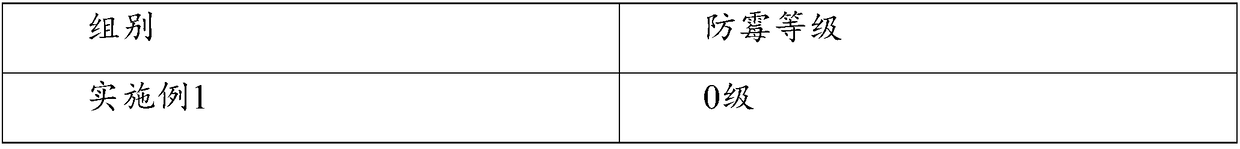

Embodiment 1

[0023] The aldehyde remover of the present embodiment includes the following components by weight, 1 part of glycine, 1 part of chitosan quaternary ammonium salt, 0.5 part of notoginseng, 0.5 part of maca root extract, 1.2 parts of glycerol, citric acid 0.5 parts of triethyl ester aqueous solution, 100 parts of deionized water.

[0024] The preparation method of the aldehyde remover of this embodiment comprises the following steps: 1) Stir the chitosan quaternary ammonium salt in boiling water until it dissolves; obtain system A; cool down the temperature of system A to 30°C. 2) Mix glycine, panax notoginseng, maca root extract, and deionized water in a reaction vessel, and stir evenly at 30°C to obtain system B; 3) After system B is dissolved, add system A to system B for mixing, and then Add glycerol and triethyl citrate aqueous solution, and stir at 30°C for 15 minutes to prepare the aldehyde remover of the present invention.

Embodiment 2

[0026] The aldehyde remover of the present embodiment comprises the following components by weight, 1.8 parts of glycine, 0.8 part of chitosan quaternary ammonium salt, 0.8 part of Panax notoginseng, 0.5 part of Maca root extract, 2 parts of glycerol, citric acid 0.6 parts of triethyl ester aqueous solution, 100 parts of deionized water.

[0027] The preparation method of the aldehyde removing agent of the present invention comprises the following steps: 1) Stir the chitosan quaternary ammonium salt in boiling water until it dissolves; obtain system A; cool down the temperature of system A to 25°C. 2) Mix glycine, panax notoginseng, maca root extract, and deionized water in a reaction vessel, and stir evenly at 25°C to obtain system B; 3) After system B is dissolved, add system A to system B for mixing, and then Add glycerol and triethyl citrate aqueous solution, and stir at 25 for 30 minutes to prepare the aldehyde remover of the present invention.

Embodiment 3

[0029] A kind of aldehyde remover of the present embodiment comprises the following components by weight, 2.5 parts of glycine, 2 parts of chitosan quaternary ammonium salt, 1 part of Panax notoginseng, 1 part of maca root extract, 3 parts of glycerol, 0.8 parts of triethyl citrate aqueous solution, 120 parts of deionized water.

[0030]The preparation method of the aldehyde removing agent of the present invention comprises the following steps: 1) Stir the chitosan quaternary ammonium salt in boiling water until it dissolves; obtain system A; cool down the temperature of system A to 28°C. 2) Mix glycine, panax notoginseng, maca root extract, and deionized water in a reaction vessel, and stir evenly at 28°C to obtain system B; 3) After system B is dissolved, add system A to system B for mixing, and then Add glycerol and triethyl citrate aqueous solution, and stir at 28°C for 20 minutes to prepare the aldehyde remover of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com