Continuous reaction device and method for oxidative stabilization of coal pitch spheres

An oxidation non-melting, reaction device technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems affecting the final product performance of the preparation process, the performance difference of different batches of products, and the inability to achieve continuous operation, etc., to achieve mechanical High efficiency and thermal efficiency, shortened oxidation time, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

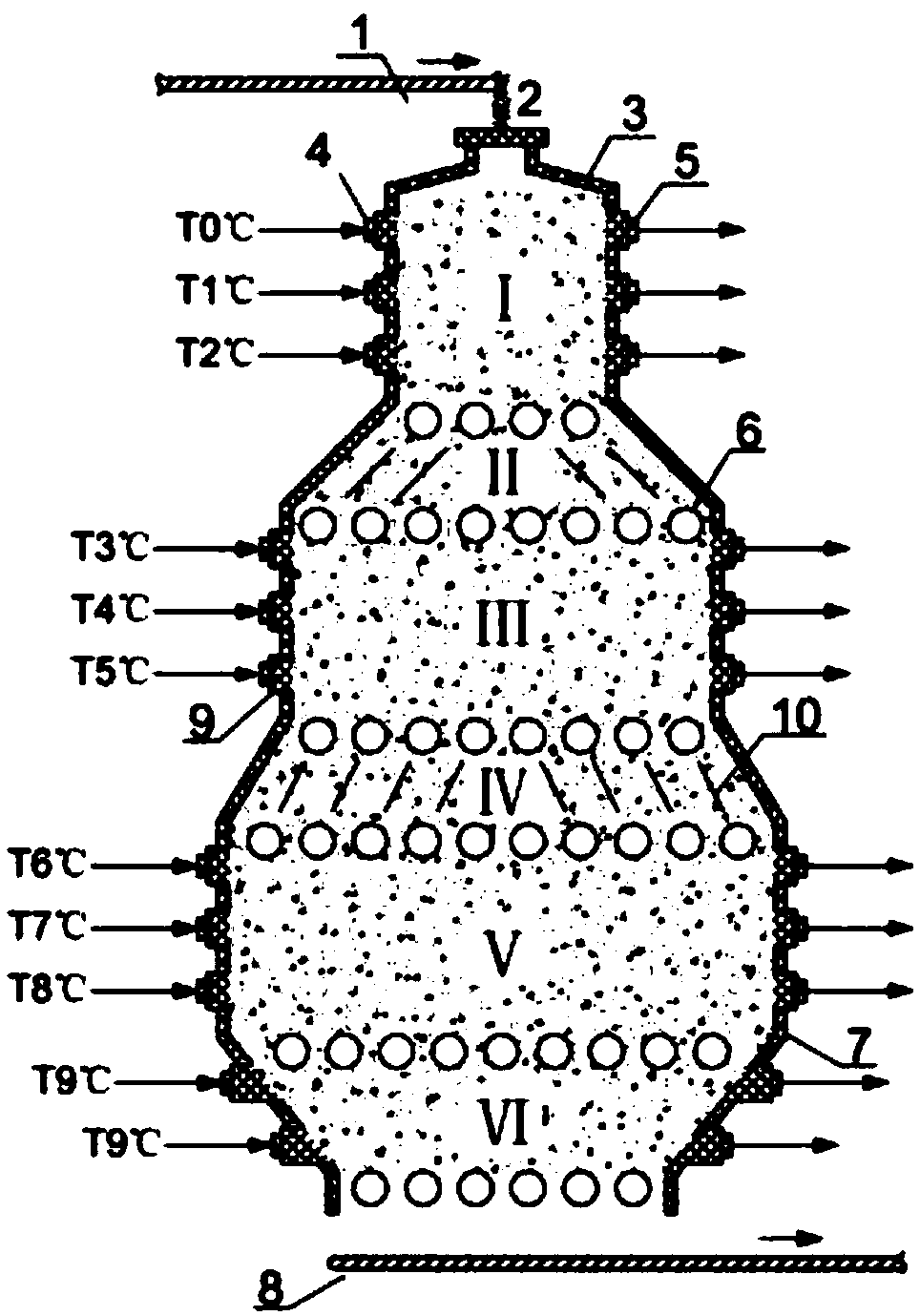

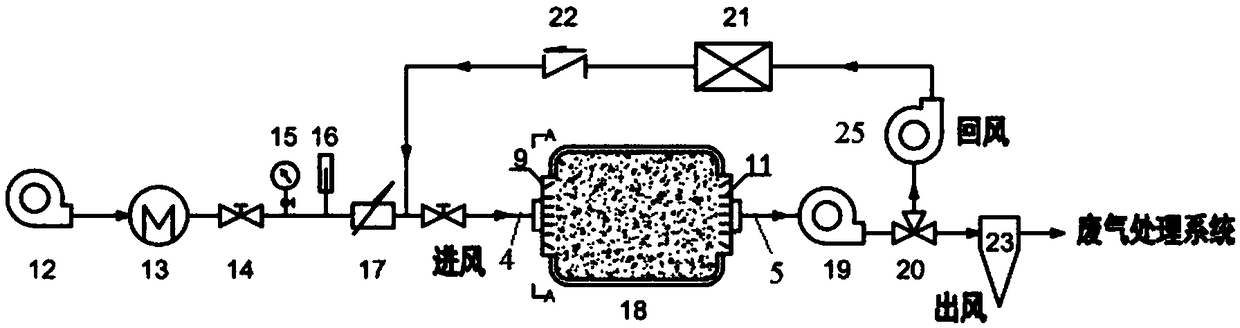

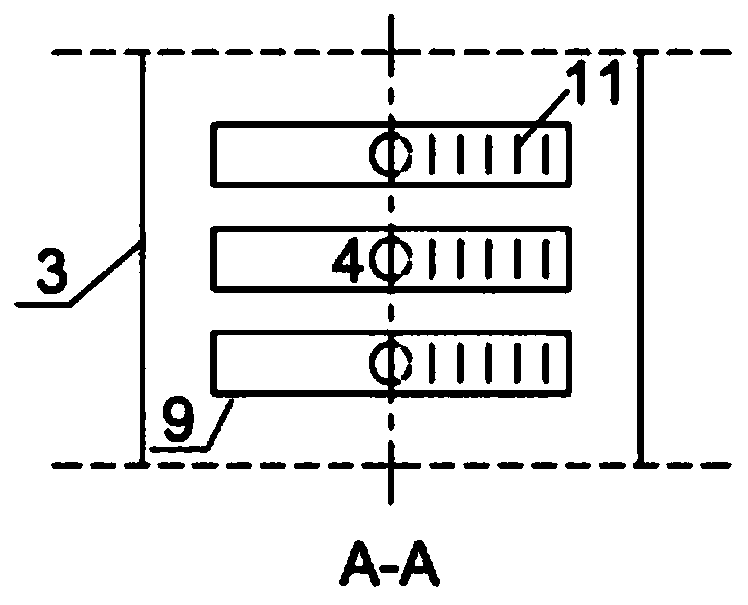

Embodiment 1

[0032] Chamber I is 0.9m long, 0.7m wide, and the filling height is 1.0m; Chamber III is 2.0m long, 1.4m wide, and the filling height is 1.0m; Chamber V is 2.5m long, 1.7m wide, and the filling height is 1.0m. , the chamber VI is a variable-diameter chamber, the length of the bottom section is 1.0m, the width is 0.9m, and the filling height is 0.7m. The diameter of the roller 6 is 20cm, the gap distance between the rollers 6 is 5cm, and the rotational angular velocity is 1.05rad / min, 0.35rad / min, 0.26rad / min, 0.21rad / min, 0.18rad / min, 0.53rad / min, respectively min. The air inlet temperatures of the three air inlets on the left side surface of the casing 7 of chamber I are 60°C, 100°C, and 140°C from top to bottom; the total air intake of chamber I is 16128m 3 / h, the air volume is 3226m 3 / h, return air volume is 12902m 3 / h; the coal tar pitch balls fell in chamber Ⅰ for 1 hour, and the temperature rose from room temperature to 140°C along the way. The air inlet temperatu...

Embodiment 2

[0035] Chamber I is 1.1m long, 0.8m wide, and the filling height is 1.1m; Chamber III is 2.1m long, 1.5m wide, and the filling height is 0.9m; Chamber V is 2.4m long, 1.6m wide, and the filling height is 1.0m. , the chamber VI is a variable-diameter chamber, the length of the bottom section is 1.1m, the width is 1.0m, and the filling height is 0.8m. The diameter of the roller 6 is 15cm, the gap distance between the rollers 6 is 6cm, and the rotation angular velocity is respectively 1.07rad / min, 0.37rad / min, 0.30rad / min, 0.25rad / min, 0.20rad / min, 0.55rad / min min. The air inlet temperatures of the three air inlets on the left side surface of the casing 7 of chamber I are 70°C, 110°C, and 150°C from top to bottom; the total air intake of chamber I is 16200m 3 / h, the air volume is 3300m 3 / h, return air volume is 12900m 3 / h; the falling process of the coal tar pitch balls in chamber Ⅰ lasted 1.1 h, and the temperature rose from room temperature to 150°C along the way. The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com