ag 2 o/sio 2 -tio 2 Method for Composite Airgel Adsorption and Removal of Thiophene Sulfides in Fuel Oil

A composite airgel and fuel oil technology, applied in chemical instruments and methods, silicon compounds, alkali metal compounds, etc., to achieve the effects of convenient operation, mild adsorption conditions, and low requirements for adsorption equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

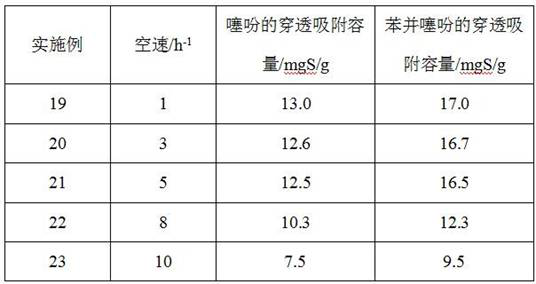

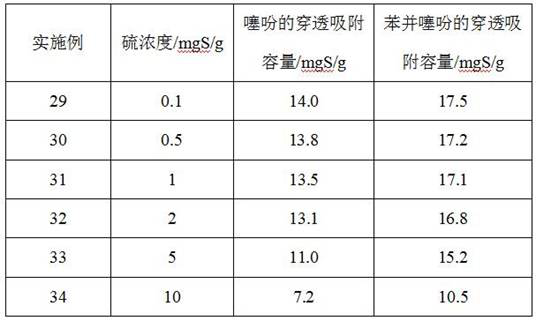

[0029] Embodiment 1~5: different silicon source, the Ag of silver source 2 O / SiO 2 -TiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0030] Ag prepared by sol-gel method 2 O / SiO 2 -TiO 2 In the composite airgel, the silicon sources used include methyl orthosilicate, ethyl orthosilicate, and silica sol, the silver sources include silver nitrate and silver acetate, and the titanium source is tetrabutyl titanate. The prepared Ag 2 O / SiO 2 -TiO 2 The composite aerogel was subjected to the penetration adsorption desulfurization experiment, and the specific operation was as follows: In the fixed bed reactor, the bottom layer was filled with an appropriate amount of absorbent cotton, and then filled with 1 g of Ag 2 O / SiO 2 -TiO 2 Airgel with appropriate amount of quartz sand. Before the adsorption experiment started, the packed adsorbent was fully wetted with n-heptane. Feed simulated gasoline, collect the adsorbed simulated ...

Embodiment 9~14

[0036] Embodiment 9~14: Ag of different molar ratios of silicon and titanium 2 O / SiO 2 -TiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0037] Choose Ag with a silicon-silver molar ratio of 50:1 and a silicon-titanium molar ratio of 5, 25, 50, 100, 150, and 200, respectively. 2 O / SiO 2 -TiO 2 Airgel, through adsorption experiments on thiophene sulfides in simulated gasoline. The space velocity is 1~5 h -1 , the adsorption temperature is 0~40℃, and the sulfur concentration of thiophene or benzothiophene in simulated gasoline is 0.1~5 mgS / g. The operation of the breakthrough adsorption experiment is the same as in Examples 1-5, and the adsorption results are shown in Table 3.

[0038] Table 3 Ag with different silicon-titanium molar ratios 2 O / SiO 2 -TiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0039]

[0040] It can be seen from Table 3 that the molar ratio of silicon ...

Embodiment 15~18

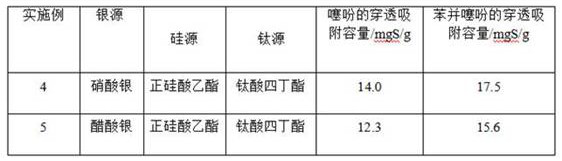

[0041] Embodiment 15~18: Ag of different molar ratios of silicon to silver 2 O / SiO 2 -TiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0042] Choose Ag with silicon-titanium molar ratio of 50:1 and silicon-silver molar ratio of 10, 20, 50, 100 respectively 2 O / SiO 2 -TiO 2 Airgel, through adsorption experiments on thiophene sulfides in simulated gasoline. The space velocity is 1~5 h -1 , the adsorption temperature is 0~40℃, and the sulfur concentration of thiophene or benzothiophene in simulated gasoline is 0.1~5 mgS / g. The operation of the breakthrough adsorption experiment is the same as in Examples 1-8, and the adsorption results are shown in Table 4.

[0043] Table 4 Ag with different silicon-silver molar ratios 2 O / SiO 2 -TiO 2 Adsorption Performance of Composite Airgel on Thiophene Sulfides in Simulated Gasoline

[0044]

[0045] It can be seen from Table 4 that Ag 2 O / SiO 2 -TiO 2 The breakthrough adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com