Mn/Ce/Cu-based low-temperature plasma catalyst as well as preparation and application

A low-temperature plasma and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, gas treatment, etc., can solve industrial application limitations, poor thermal stability, chemical stability, etc. problems, such as high selectivity, high porosity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

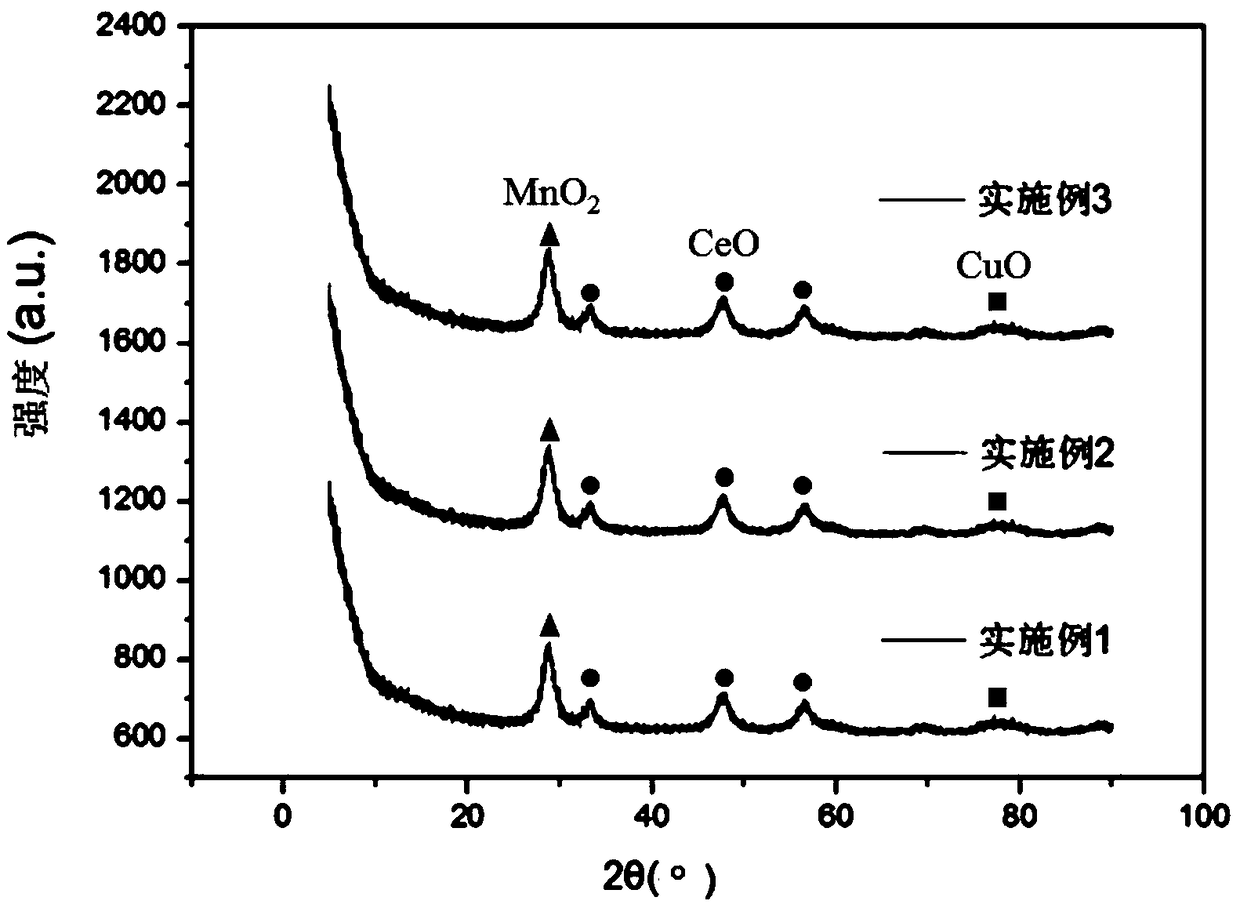

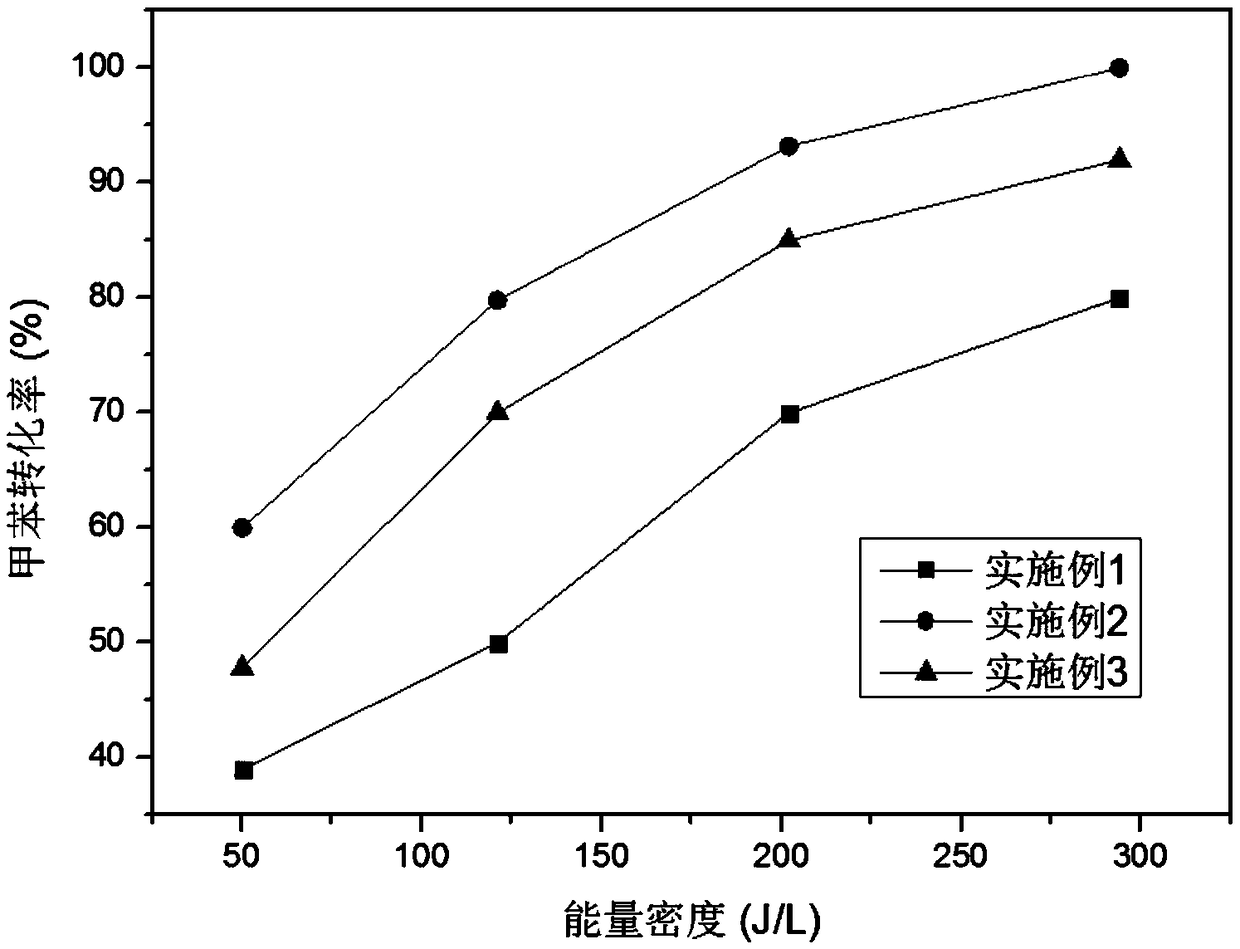

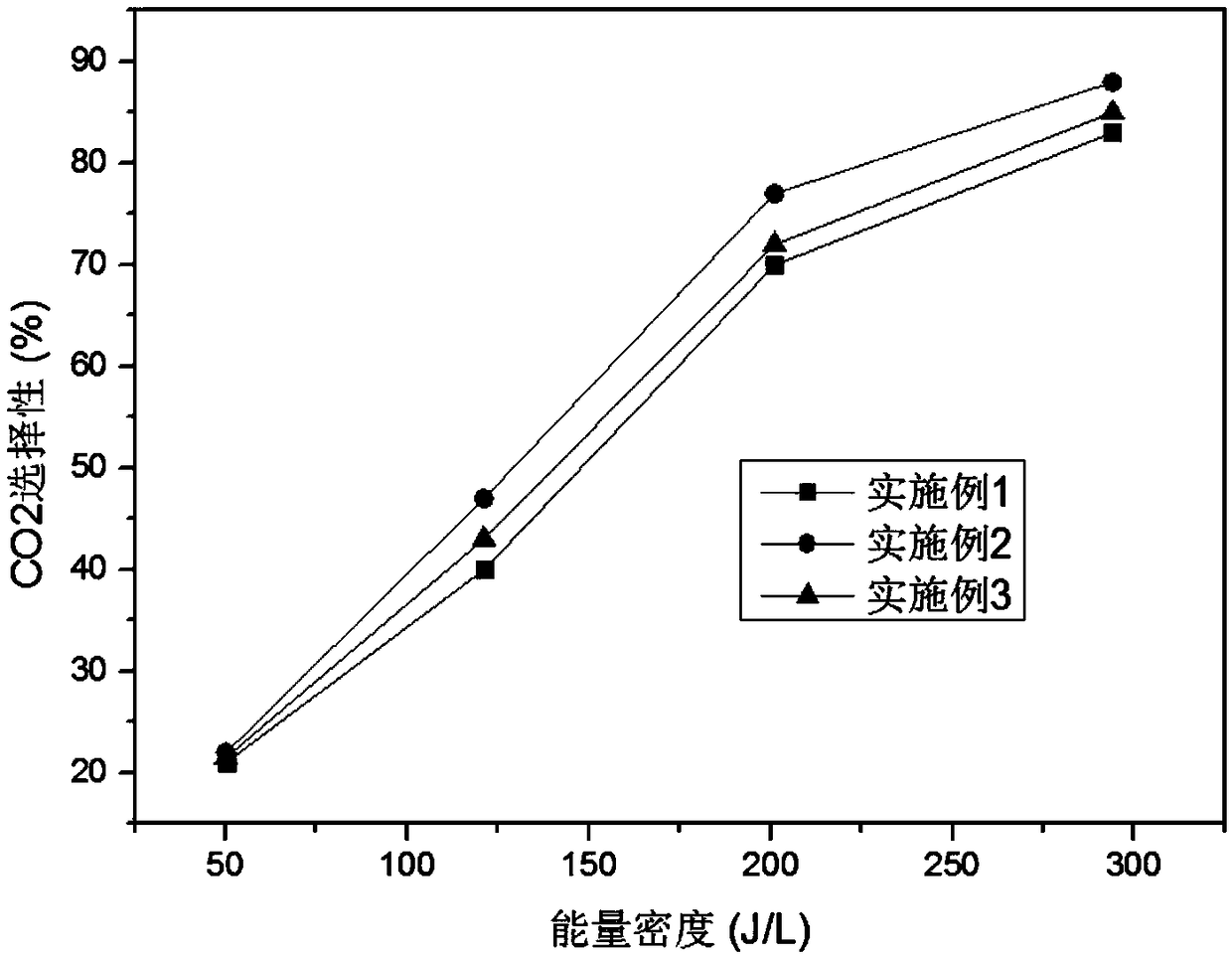

Embodiment 1

[0032] (1) 520 μL of 50% Mn(NO 3 ) 2 Aqueous solution, 1.94gCe(NO 3 ) 3 ·6H 2 O and 0.54gCu(NO 3 ) 2 ·3H 2 O was added to 80 mL of DMF, 1000 μL of formic acid was added, and ultrasonically mixed for 10 min to obtain a mixed solution;

[0033] (2) Place the mixed solution in an oven at 80°C for 10 hours. After the solution is cooled, remove the supernatant, add fresh DMF, soak and activate at room temperature for 12 hours, and obtain an activated crystal material (Mn / Ce / Cu-MOF);

[0034] (3) The activated crystal material is washed with DMF, filtered, and the filtered material is dried in a vacuum oven at 50°C; the dried crystal material is put into a muffle furnace and roasted at 300°C for 2h to obtain Mn / Ce / Cu based low temperature plasma catalyst.

Embodiment 2

[0036] (1) 520 μL of 50% Mn(NO 3 ) 2 Aqueous solution, 1.94gCe(NO 3 ) 3 ·6H 2 O and 0.81gCu(NO 3 ) 2 ·3H 2 O was added to 80 mL of DMF, 1200 μL of formic acid was added, and ultrasonically mixed for 10 min to obtain a mixed solution;

[0037] (2) Place the mixed solution in an oven at 100°C for 12 hours. After the solution is cooled, remove the supernatant, add fresh DMF, soak and activate at room temperature for 18 hours, and obtain an activated crystal material (Mn / Ce / Cu-MOF);

[0038](3) The activated crystal material is washed with DMF, filtered, and the filtered material is dried in a vacuum oven at 50°C; the dried crystal material is baked in a muffle furnace at 350°C for 2.5h to obtain Mn / Ce / Cu based low temperature plasma catalyst.

Embodiment 3

[0040] (1) 520 μL of 50% Mn(NO 3 ) 2 Aqueous solution, 1.94gCe(NO 3 ) 3 ·6H 2 O and 1.08gCu(NO 3 ) 2 ·3H 2 O was added to 80 mL of DMF, 1500 μL of formic acid was added, and ultrasonically mixed for 10 min to obtain a mixed solution;

[0041] (2) Place the mixed solution in an oven at 120°C for 15 hours. After the solution is cooled, remove the supernatant, add fresh DMF, soak and activate at room temperature for 24 hours, and obtain an activated crystal material (Mn / Ce / Cu-MOF);

[0042] (3) The activated crystal material is washed with DMF, filtered, and the filtered material is dried in a vacuum oven at 50° C.; the dried crystal material is put into a muffle furnace and roasted at 400° C. for 3 hours to obtain Mn / Ce / Cu based low temperature plasma catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com