Technology for preparing two-dimensional MOF material by one-step solvothermal method

A solvothermal method and process technology, which is applied in the field of one-step solvothermal preparation of two-dimensional MOF materials, can solve the problems of narrow application range, complex operation, uneven sheet, etc., and achieve uniform distribution of components, simple process steps, and uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

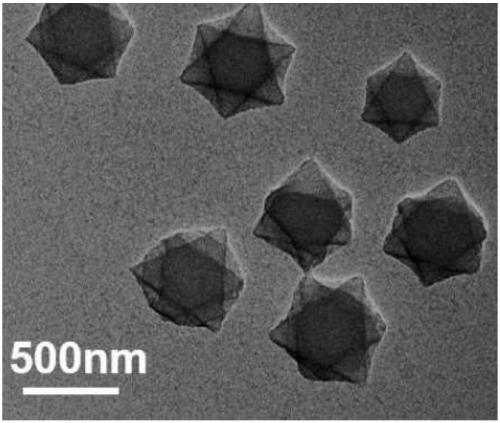

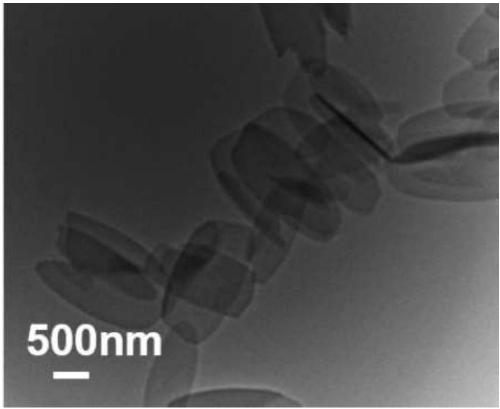

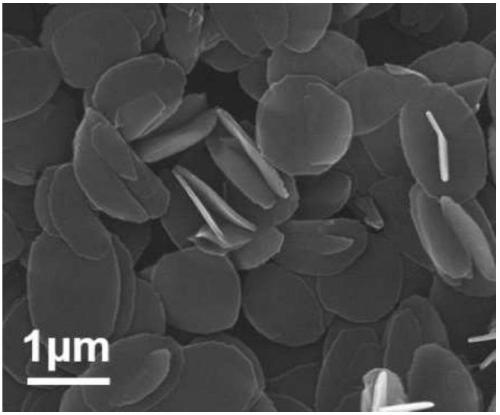

Image

Examples

Embodiment 1

[0035] Disperse the above-mentioned MIL-53(Fe) three-dimensional MOF material into methanol to obtain a dispersion liquid with a concentration of 0.1 mg / mL; pour the dispersion liquid into the reaction kettle and react at 60°C for 10 hours. The obtained product was naturally cooled to 10°C, then washed by centrifugation with methanol or ethanol, repeated once, and dried in vacuum for 6 hours to obtain the MIL-53(Fe) two-dimensional MOF material.

Embodiment 2

[0037] Disperse the above MIL-53(Fe) three-dimensional MOF material into ethanol to obtain a dispersion solution with a concentration of 10 mg / mL; pour the dispersion solution into the reaction kettle and react at 200°C for 1 hour. After the reaction, the obtained The product was naturally cooled to 40°C, then washed with methanol or ethanol by centrifugation, repeated 5 times, and dried in vacuum for 10 hours to obtain the MIL-53(Fe) two-dimensional MOF material.

Embodiment 3

[0039] Disperse the above-mentioned MIL-53(Fe) three-dimensional MOF material into ethanol to obtain a dispersion liquid with a concentration of 0.56 mg / mL; pour the dispersion liquid into the reaction kettle and react at 120°C for 8 hours. After the reaction, put The obtained product was naturally cooled to 25°C, then centrifuged and washed with methanol or ethanol, repeated three times, and vacuum-dried for 8 hours to obtain the MIL-53(Fe) two-dimensional MOF material.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap