Reactive phosphorus-containing flame retardant and preparation method and application thereof

A flame retardant and reactive technology, applied in the field of flame retardants, can solve problems such as cumbersome process flow and complex synthesis methods of flame retardants, and achieve the effects of wide application range, excellent durability, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

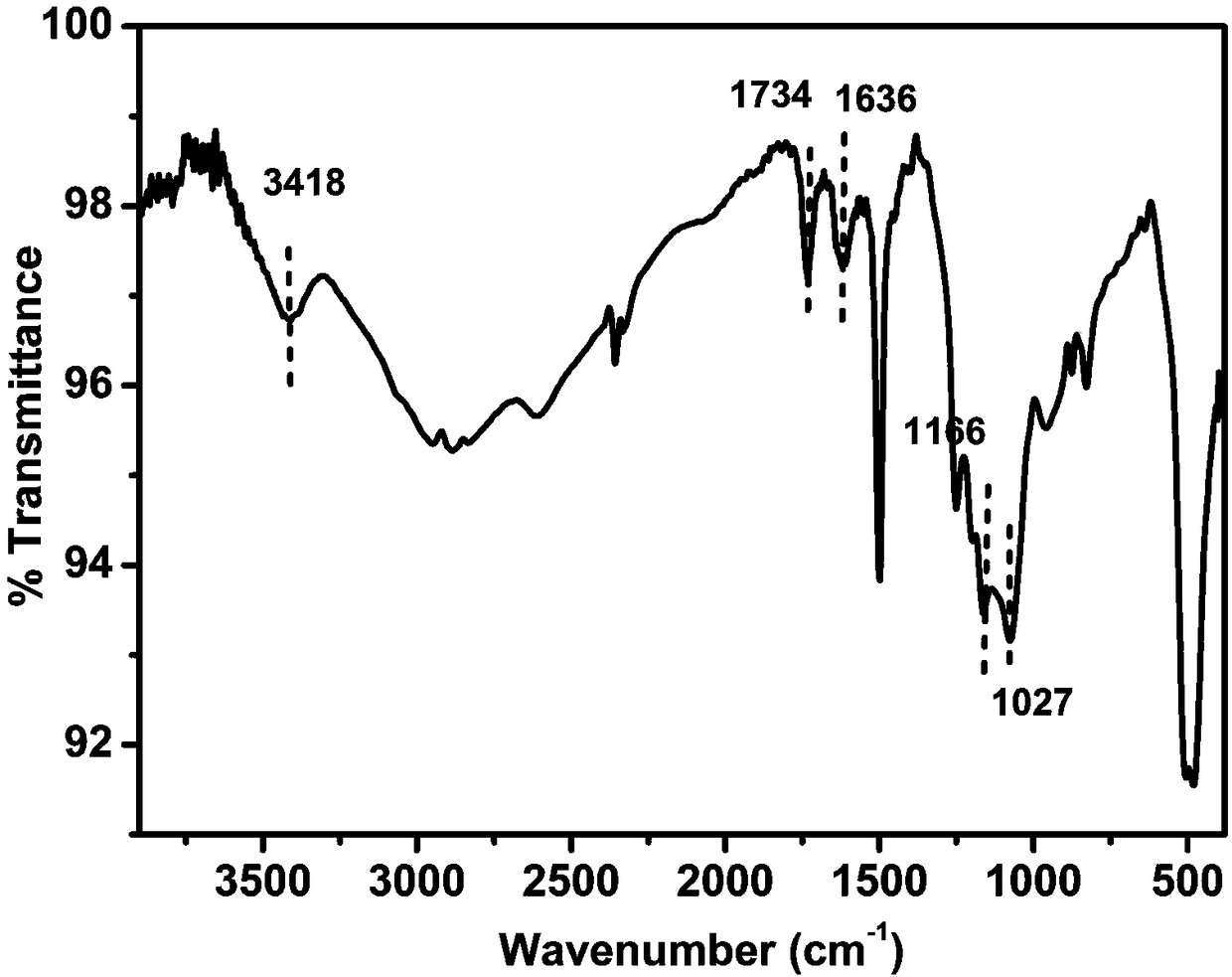

[0040] First, under the protection of nitrogen, add 0.2 mol of phosphorus oxychloride to 150 mL of tetrahydrofuran at 0~-5°C and mix well, then add 0.6 mol of triethylamine at this temperature, and then slowly add 50 mL of it dropwise within 2 hours After the dropwise addition of 0.2 mol of hydroxyethyl acrylate dissolved in tetrahydrofuran was completed, the reaction was continued at the temperature for 6 hours to obtain a solution of a single-substituted phosphorus-containing intermediate (III) containing a double bond structure. Add 0.2 mol of triethylamine to the intermediate (Ⅲ) solution obtained in the above step at room temperature, then slowly add 0.2 mol of 4,4-diaminodiphenyl ether dissolved in 60 mL of tetrahydrofuran dropwise within 2 hours, after the dropwise addition is completed Raise the temperature of the solution to 100°C and react for 8 hours. After the reaction, the liquid is removed by suction filtration, and the obtained yellow solid is washed with deioniz...

Embodiment 2

[0042] First, under the protection of nitrogen, add 0.22mol phosphorus oxychloride to 150mL acetonitrile at 0~-10℃ and mix well, then add 0.66mol pyridine at this temperature, then slowly add 50mL acetonitrile dropwise within 1.5h to dissolve 0.2mol of hydroxyethyl acrylate, after the dropwise addition, the reaction was continued at this temperature for 7 hours to obtain a solution of a single-substituted phosphorus-containing intermediate (Ⅲ) containing a double bond structure. Add 0.2 mol of pyridine to the solution of intermediate (Ⅲ) obtained in the above step at room temperature, then slowly add 0.2 mol of 4,4-diaminodiphenylmethane dissolved in 60 mL of acetonitrile dropwise within 2 hours, and dissolve the solution after the dropwise addition The temperature is raised to 90°C and reacted for 7 hours. After the reaction, the liquid is removed by suction filtration, and the obtained yellow solid is washed with deionized water for 3 to 4 times. After drying, the reactive ph...

Embodiment 3

[0044] First, under the protection of nitrogen, add 0.2 mol of phosphorus oxychloride to 150 mL of tetrahydrofuran at 0~-5°C and mix well, then add 0.7 mol of triethylamine at this temperature, and then slowly add 50 mL of it dropwise within 2 hours After the dropwise addition of 0.2 mol of hydroxyethyl acrylate dissolved in tetrahydrofuran was completed, the reaction was continued at the temperature for 6 hours to obtain a solution of a single-substituted phosphorus-containing intermediate (III) containing a double bond structure. Add 0.2 mol of triethylamine to the intermediate (Ⅲ) solution obtained in the above steps at room temperature, then slowly add 0.2 mol of 4,4-diaminodiphenyl ether dissolved in 60 mL of tetrahydrofuran dropwise within 2 hours, The temperature of the solution is raised to 85°C and reacted for 8 hours. After the reaction, the liquid is removed by suction filtration, and the obtained yellow solid is washed with deionized water for 3 to 4 times. After dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com