Waterborne epoxy zinc-rich primer for railway wagon and preparation method of waterborne epoxy zinc-rich primer

A water-based epoxy zinc-rich technology for railway wagons, which is applied in the field of coatings to achieve the effects of safe construction process, short drying time and better construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

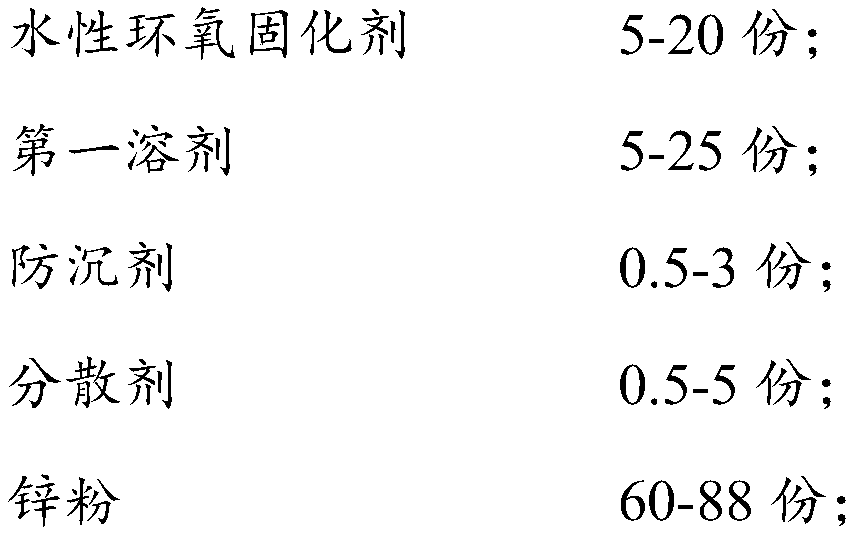

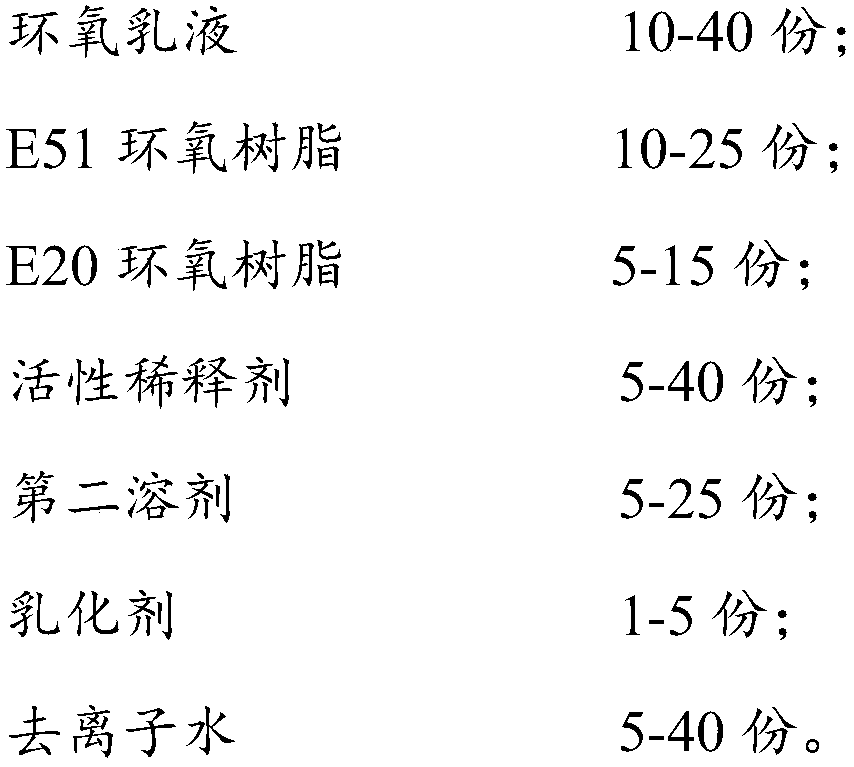

[0031] A water-based epoxy zinc-rich primer for railway wagons, which is formed by mixing component A and component B according to a mass ratio of 2:1;

[0032] Wherein, the preparation method of component A comprises the steps:

[0033] 1) Add 5 parts by weight of XZ-H180, part of ethylene glycol monobutyl ether, and 0.5 parts by weight of 6208-40 into the dispersion tank in sequence, and disperse and mix evenly;

[0034] 2) Add 0.5 parts by weight of A300 and 60 parts by weight of 400-mesh zinc powder to the feed liquid prepared in step 1), disperse at a high speed to a fineness≤80 microns, and then use the remaining ethylene glycol monobutyl ether (two batches of The total consumption of ethylene glycol monobutyl ether is 5 parts by weight) its viscosity is adjusted (ISO6# cup) to ≥ 30 seconds, packed after filtering and removing impurities;

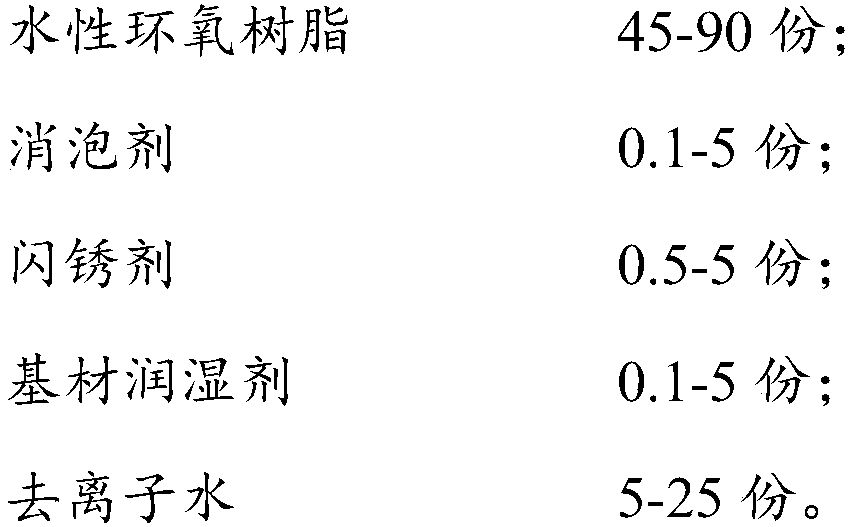

[0035] Wherein, the preparation method of B component is:

[0036] Add 45 parts by weight of water-based epoxy resin, 0.1 part by ...

Embodiment 2

[0042] A water-based epoxy zinc-rich primer for railway wagons, which is formed by mixing component A and component B according to a mass ratio of 3:1;

[0043] Wherein, the preparation method of component A comprises the steps:

[0044] 1), add 12 parts by weight of Banco905, part of propylene glycol methyl ether, and 2.7 parts by weight of Tego740 into the dispersion tank in sequence, and disperse and mix evenly;

[0045] 2), 1.7 parts by weight of A200, 73 parts by weight of 1000-mesh zinc powder are added to the feed liquid prepared in step 1), dispersed at a high speed to a fineness≤80 microns, and then use the remaining propylene glycol methyl ether (two batches of propylene glycol The total consumption of methyl ether is 15 parts by weight) and its viscosity is adjusted (ISO6# cup) to ≥ 30 seconds, and packed after filtering and removing impurities;

[0046] The preparation method of B component is:

[0047] Add 67 parts by weight of water-based epoxy resin, 3.1 parts...

Embodiment 3

[0053] A water-based epoxy zinc-rich primer for railway wagons, which is formed by mixing Component A and Component B according to a mass ratio of 4:1;

[0054] Wherein, the preparation method of component A comprises the steps:

[0055] 1) Add 20 parts by weight of XZ-H180, part of propylene glycol methyl ether, and 5 parts by weight of Tego740 into the dispersion tank in sequence, and disperse and mix evenly;

[0056] 2), 3 parts by weight of A300, 88 parts by weight of 1000 mesh zinc powder are added to the feed liquid prepared in step 1), dispersed at a high speed to a fineness≤80 microns, and then use the remaining propylene glycol methyl ether (two batches of propylene glycol The total consumption of methyl ether is 25 parts by weight) its viscosity is adjusted to (ISO6# cup) to ≥ 30 seconds, and it is packed after filtering and removing impurities;

[0057] The preparation method of B component is:

[0058] Add 90 parts by weight of water-based epoxy resin, 5 parts by w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap