Multifunctional electroplating device

An electroplating device and multi-functional technology, applied in sealing devices, plating tanks, electrolysis processes, etc., can solve the problems of not allowing deep digging of electroplating pools, poor adaptability, and large engineering volume, etc., to improve quality and adaptability, reduce The effect of engineering investment and saving space distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, those skilled in the art All other embodiments obtained by personnel without creative work belong to the protection scope of the present invention.

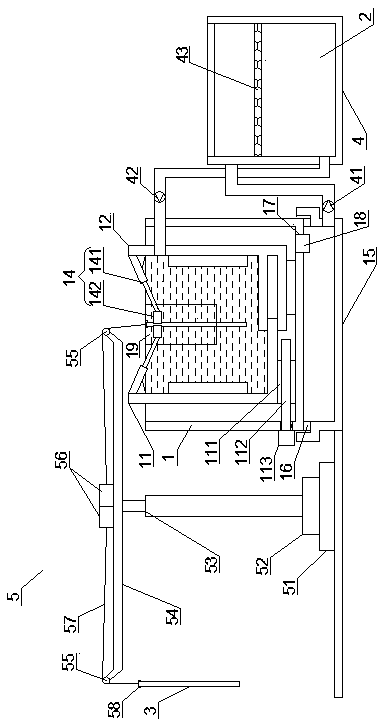

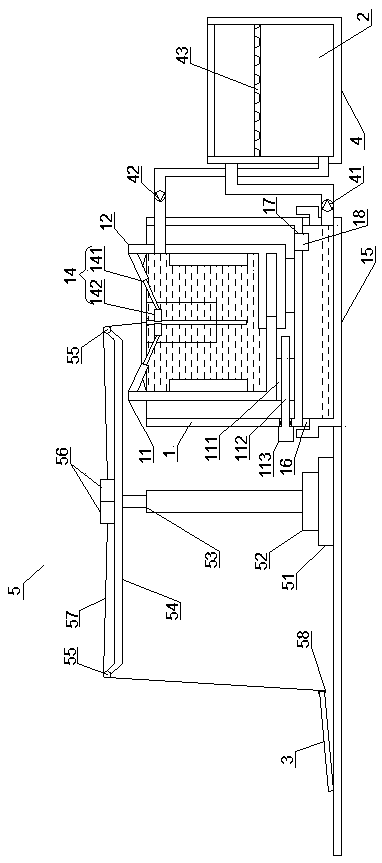

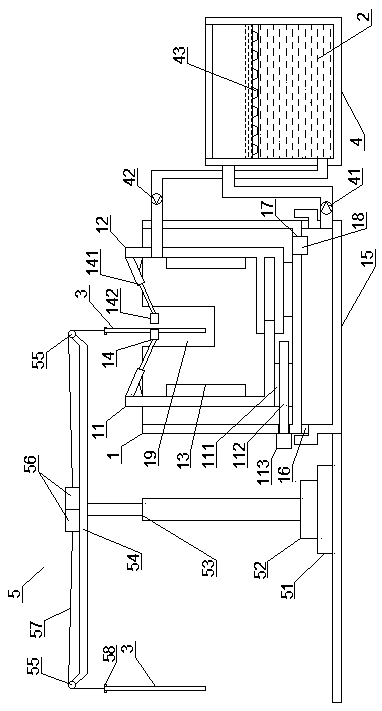

[0028] Such as Figure 1 to Figure 3 As shown, the multifunctional electroplating device of the present embodiment includes an electroplating tank 1, and the electroplating tank 1 is provided with a movable door 19 that can be pushed and closed. front and back. The electroplating tank 1 is provided with a left half tank body 11 and a right half tank body 12, the left half tank body 11 and the right half tank body 12 are square structures, and the end of the right half tank body 12 is provided with a seal Leakproof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com