Construction method of toilet waterproof decoration structure

A technology for decorative structures and construction methods, applied to building components, building insulation materials, etc., can solve the problems of reduced bonding ability, poor waterproof effect, and easy gaps, etc., to achieve improved waterproof performance, good waterproof effect, and improved low temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A construction method for a toilet waterproof decoration structure, comprising the following steps:

[0046] Step 1: Clean the base layer of the bathroom floor first, and then level it with cement mortar;

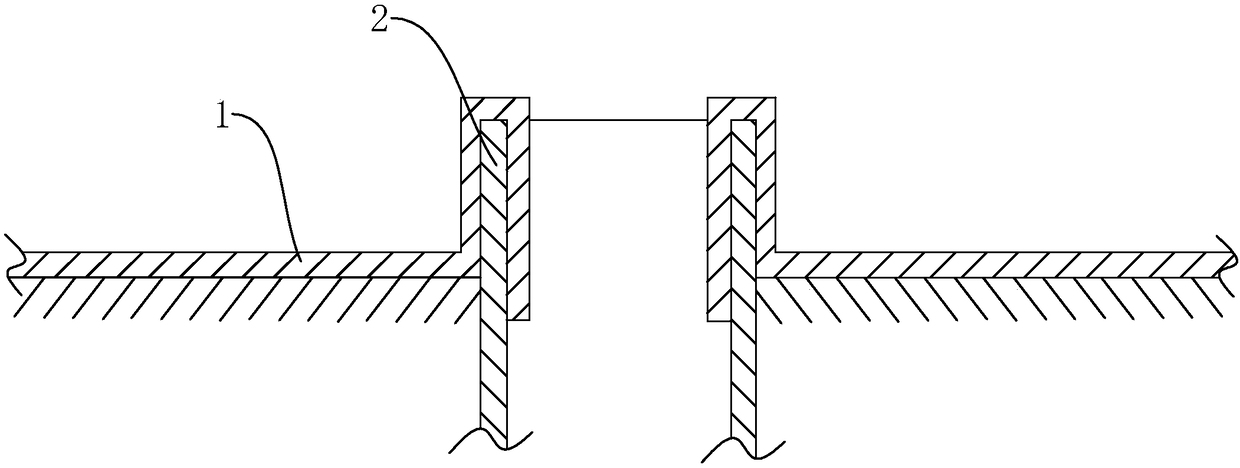

[0047] Step 2: Apply waterproof paint on the surface of the bathroom leveling layer, and then lay polypropylene cloth 1, which wraps the outer surface of the floor drain pipe 2 and extends from the upper opening of the floor drain pipe 2 to stick to its inner surface;

[0048] Step 3: First use waterproof concrete to find a slope on the polypropylene cloth 1, make the ground slope, and the floor drain pipe 2 is located at a low place on the ground, with a slope difference of half a centimeter to two centimeters, and then lay tiles.

[0049] The gap between the floor drain pipe 2 and the ground is completely covered by the polypropylene cloth 1, making it difficult for water to seep down there, and the waterproof performance of the toilet floor is greatly improved.

Embodiment 2

[0051] The waterproof coating in embodiment one comprises the components of following parts by weight:

[0052] 60 parts of bisphenol A type epoxy resin;

[0053] 45 parts of petroleum pitch;

[0054] 6 parts of benzyldimethylamine;

[0055] 12 parts of Mannich modified amine;

[0056] 12 parts polyamide;

[0057] 3 parts talcum powder;

[0058] 1.5 parts of titanium dioxide;

[0059] 5 parts tire rubber powder;

[0060] 0.5 part of silane coupling agent;

[0061]5 parts of nano silicon dioxide;

[0062] 4 parts of mica iron oxide.

[0063] 3 parts zinc phosphate.

[0064] 0.5 parts of polyphosphoric acid.

[0065] Subtract 5 parts of the third-line oil.

[0066] 2 parts of triphenylphosphine.

[0067] The model of bisphenol A epoxy resin is E-44, purchased from Hubei Qibajiu Chemical Co., Ltd.; benzyl dimethylamine is purchased from Shanghai Deyin Chemical Co., Ltd.; the model of Mannich modified amine is T-31 , purchased from Shanghai Resin Factory; polyamide mo...

Embodiment 3

[0072] The waterproof coating in embodiment one comprises the components of following parts by weight:

[0073] 40 parts of bisphenol A type epoxy resin;

[0074] 30 parts of petroleum asphalt;

[0075] 4 parts of benzyldimethylamine;

[0076] 8 parts of Mannich modified amine;

[0077] 8 parts polyamide;

[0078] 1 part talcum powder;

[0079] 0.5 parts of titanium dioxide;

[0080] 2 parts tire rubber powder;

[0081] 0.2 parts of silane coupling agent;

[0082] 3 parts of nano silicon dioxide;

[0083] 1 part of mica iron oxide.

[0085] 0.2 parts of polyphosphoric acid.

[0086] Subtract 2 parts of the third-line oil.

[0087] 1 part of triphenylphosphine.

[0088] The model of bisphenol A epoxy resin is E-44, purchased from Hubei Qibajiu Chemical Co., Ltd.; benzyl dimethylamine is purchased from Shanghai Deyin Chemical Co., Ltd.; the model of Mannich modified amine is T-31 , purchased from Shanghai Resin Factory; polyamide mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com