Chip type oxygen sensor for novel double battery type motorcycle and preparation method thereof

An oxygen sensor and dual-battery technology, applied in the field of a new type of dual-battery type motorcycle chip oxygen sensor and its preparation, can solve the problems of poor precision and large volume, achieve improved response time and signal stability, reduced size, The effect of improving test accuracy and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

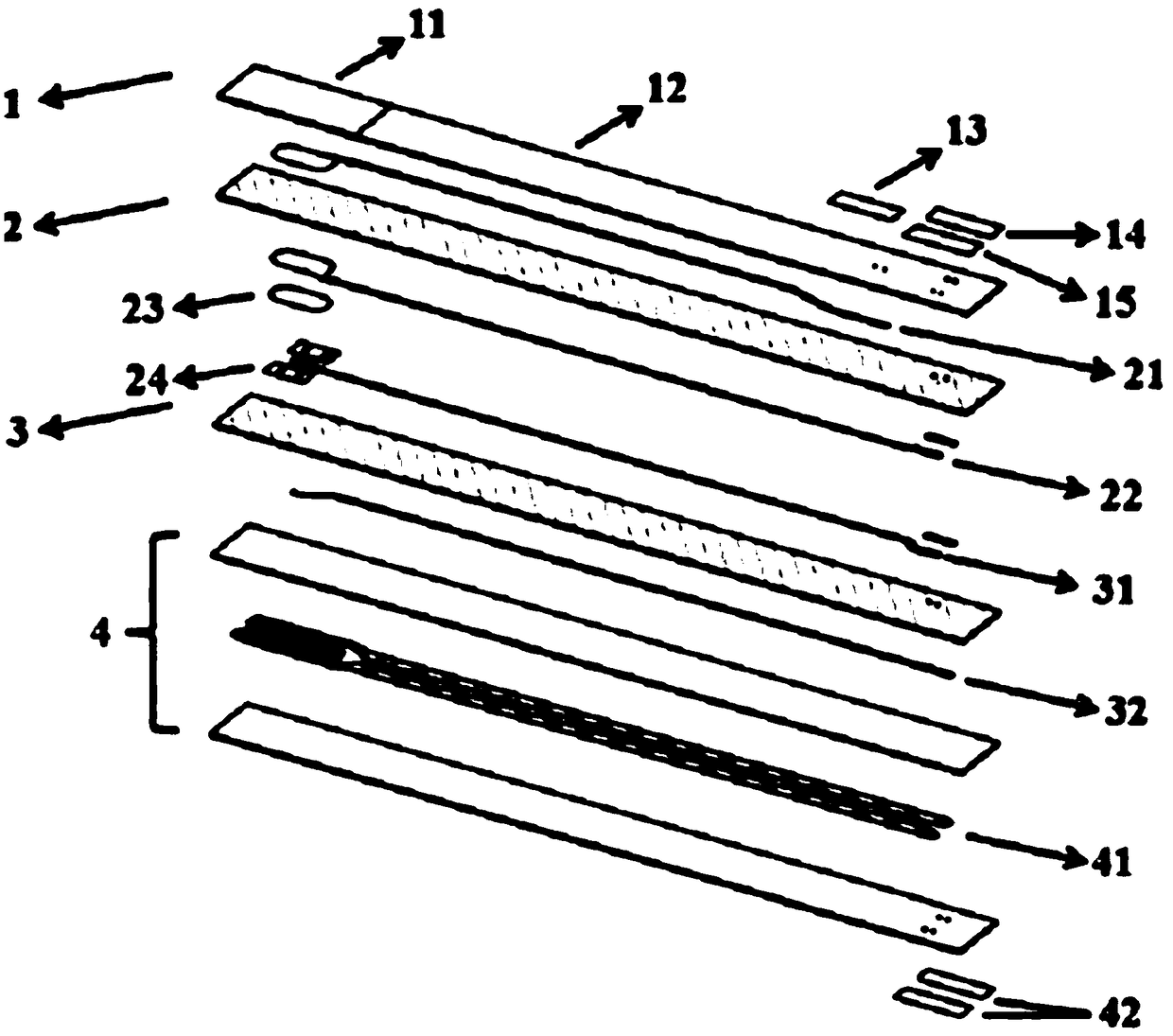

[0042] Such as figure 1 As shown, the sensor includes a porous and outer protective layer 1, an oxygen pump cell 2, a reference cell 3, and a heating layer 4. Each layer is laminated from top to bottom and then sintered. The porous and outer protective layer 1 comprises a combination of a porous alumina layer 11 made of a porous alumina casting substrate and an alumina layer 12 made of an alumina casting substrate. The porous alumina layer 11 completely covers the pump. Oxygen external electrode 21, the aluminum oxide layer 12 covers the external electrode leads, the sensor signal is led out from the through holes on the aluminum oxide layer 12 and the electrode pins. The electrode pins include a first pin 13, a second pin 14 and a third lead Foot 15. The pumping oxygen cell 2 includes a first zirconia cast substrate. The upper surface of the first zirconia cast substrate is provided with a pumping oxygen external electric stage 21. The pumping oxygen external electric stage 2...

Embodiment 2

[0044] The manufacturing method of a novel double-battery type oxygen sensor for motorcycles includes the following steps:

[0045] Step S1: preparing zirconia ceramic slurry, alumina ceramic slurry and porous alumina ceramic slurry:

[0046] (1) Mix zirconium oxide, yttrium oxide, aluminum oxide 1, solvent, dispersant, binder, and plasticizer according to mass percentage: 40:6:10:35:1:5:3, and then ball mill to form Zirconia ceramic slurry;

[0047] Mix alumina 1, alumina 2, sintering aids, solvents, dispersants, binders, and plasticizers according to mass percentage: 40:4:4:40:2:5:5, and then ball mill to form oxidation Aluminum ceramic paste;

[0048] Mix alumina 1, alumina 2, carbon powder, solvent, dispersant, binder, and plasticizer according to mass percentage: 25:8:7:50:1:5:4, and then ball mill to form porous oxidation Aluminum ceramic paste;

[0049] Among them, the particle size range of alumina 1 (D50): 0.1μm, the specific surface area range: 10m 2 / g; Alumina 2 particle ...

Embodiment 3

[0059] Step S1: preparing zirconia ceramic slurry, alumina ceramic slurry and porous alumina ceramic slurry:

[0060] Mix zirconium oxide, yttrium oxide, aluminum oxide 1, solvent, dispersant, binder, and plasticizer according to mass percentage: 48:6.5:9:25:2.5:4.5:4.5, and then ball mill to form zirconia ceramics Slurry

[0061] Mix alumina 1, alumina 2, sintering aids, solvents, dispersants, binders, and plasticizers according to mass percentage: 48.5:3:5:35:1.5:4:3, and then ball mill to form oxidation Aluminum ceramic paste;

[0062] Mix alumina 1, alumina 2, carbon powder, solvent, dispersant, binder, and plasticizer according to mass percentage: 33.5:4:4:48:1.5:6:3, and then ball mill to form porous oxidation Aluminum ceramic slurry; the particle size range of alumina 1 (D50): 0.8μm, the specific surface area range: 6m 2 / g; Alumina 2 particle size range (D50): 2μm, specific surface area range: 60m 2 / g;

[0063] Step S2: Use the casting method to cast the above three ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com