Evaluation method of scale inhibition rate of scale inhibitor with high barium sulfate scale content for oil field

An evaluation method and technology of antiscalants, which are applied in the direction of chemical analysis by titration method, can solve the problems of reducing detection cost and large actual differences, and achieve the effects of low detection cost, simple operation and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

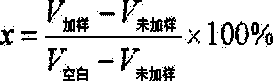

Method used

Image

Examples

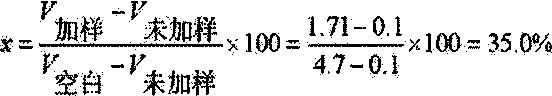

Embodiment 1

[0068] The following reagents are of analytical grade:

[0069] Oilfield formation water A solution: prepare 1 liter of solution, including 2035mg barium chloride and 30.0g sodium chloride.

[0070] Oilfield injection water B solution; prepare 1 liter of solution, of which sodium sulfate 2250mg, sodium chloride 2000mg.

[0071] Scale inhibitor C solution: Weigh 1.00g of scale inhibitor (weigh to 0.01g), dissolve it with a small amount of distilled water and transfer to a 1000mL volumetric flask to dilute to the mark. The solution contains 1.0mg / mL of scale inhibitor.

[0072] 0.01mol / l EDTA disodium magnesium solution (4.30g EDTA disodium magnesium, dissolved in distilled water and diluted to 1000mL); 0.0124mol / l EDTA standard solution; chrome black T indicator; PH=10 ammonia-ammonium chloride buffer Solution; calcium reagent indicator; 50% hydrochloric acid solution (buffer solution); constant temperature water bath or constant temperature oven; analytical balance; sterile, clean, co...

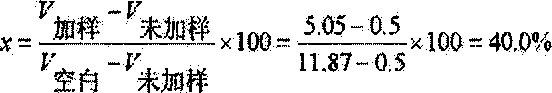

Embodiment 2

[0093] The following reagents are of analytical grade:

[0094] Oilfield formation water A solution: prepare 1 liter of solution, including 2035mg barium chloride and 30.0g sodium chloride.

[0095] Oilfield injection water B solution; prepare 1 liter of solution, of which sodium sulfate 2250mg, sodium chloride 2000mg.

[0096] Scale inhibitor C solution: Weigh 1.00g of scale inhibitor (weigh to 0.01g), dissolve it with a small amount of distilled water and transfer to a 1000mL volumetric flask to dilute to the mark. The solution contains 1.0mg / mL of scale inhibitor.

[0097] 0.01mol / l EDTA disodium magnesium solution (4.30g EDTA disodium magnesium, dissolved in distilled water and diluted to 1000mL); 0.0124mol / l EDTA standard solution; chrome black T indicator; PH=10 ammonia-ammonium chloride buffer Solution; calcium reagent indicator; 50% hydrochloric acid solution (buffer solution); constant temperature water bath or constant temperature oven; analytical balance; sterile, clean, co...

Embodiment 3

[0118] The following reagents are of analytical grade:

[0119] Oilfield formation water A solution: prepare 1 liter of solution, including 2035mg barium chloride and 30.0g sodium chloride.

[0120] Oilfield injection water B solution; prepare 1 liter of solution, of which sodium sulfate 2250mg, sodium chloride 2000mg.

[0121] Scale inhibitor C solution: Weigh 1.00g of scale inhibitor (weigh to 0.01g), dissolve it with a small amount of distilled water and transfer to a 1000mL volumetric flask to dilute to the mark. The solution contains 1.0mg / mL of scale inhibitor.

[0122] 0.01mol / l EDTA disodium magnesium solution (4.30g EDTA disodium magnesium, dissolved in distilled water and diluted to 1000mL); 0.0124mol / l EDTA standard solution; chrome black T indicator; PH=10 ammonia-ammonium chloride buffer Solution; calcium reagent indicator; 50% hydrochloric acid solution (buffer solution); constant temperature water bath or constant temperature oven; analytical balance; sterile, clean, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com