Microsensor controllable array preparation method using tobacco mosaic virus as template

A technology of tobacco mosaic virus and micro-sensor, which is applied in the directions of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult to realize the preparation of complex microstructures and controllable arrays, complex preparation processes, expensive equipment, etc. Sensitivity, increased contact area, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

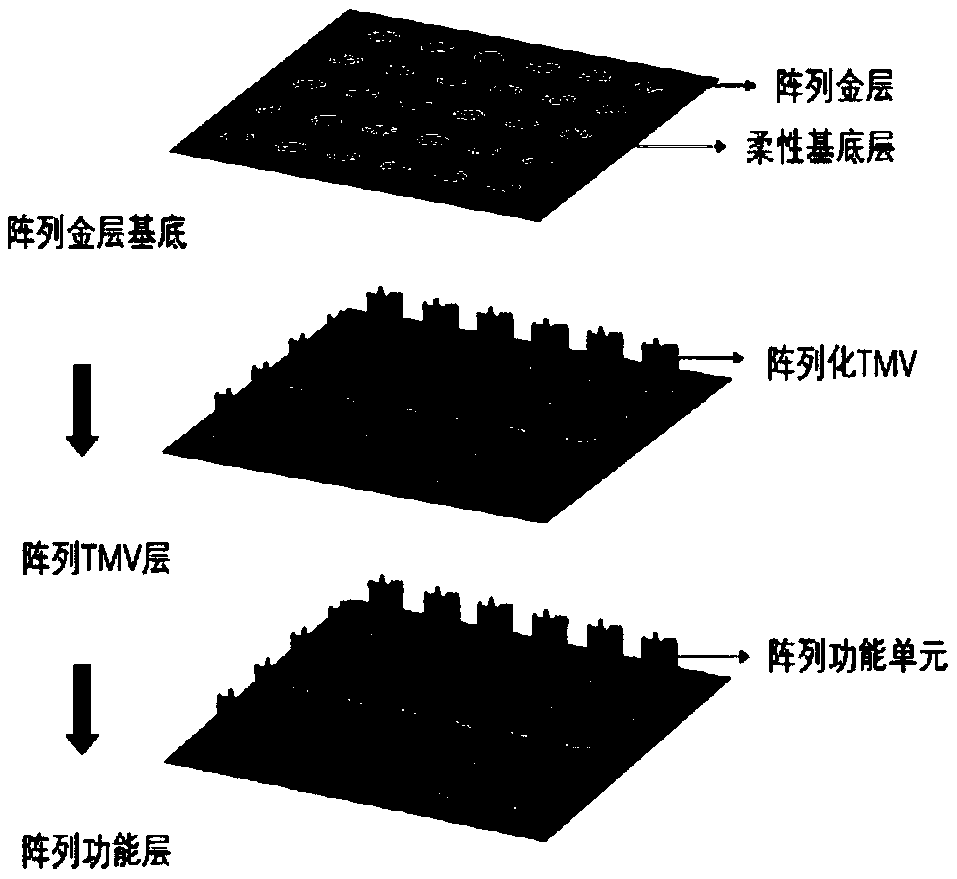

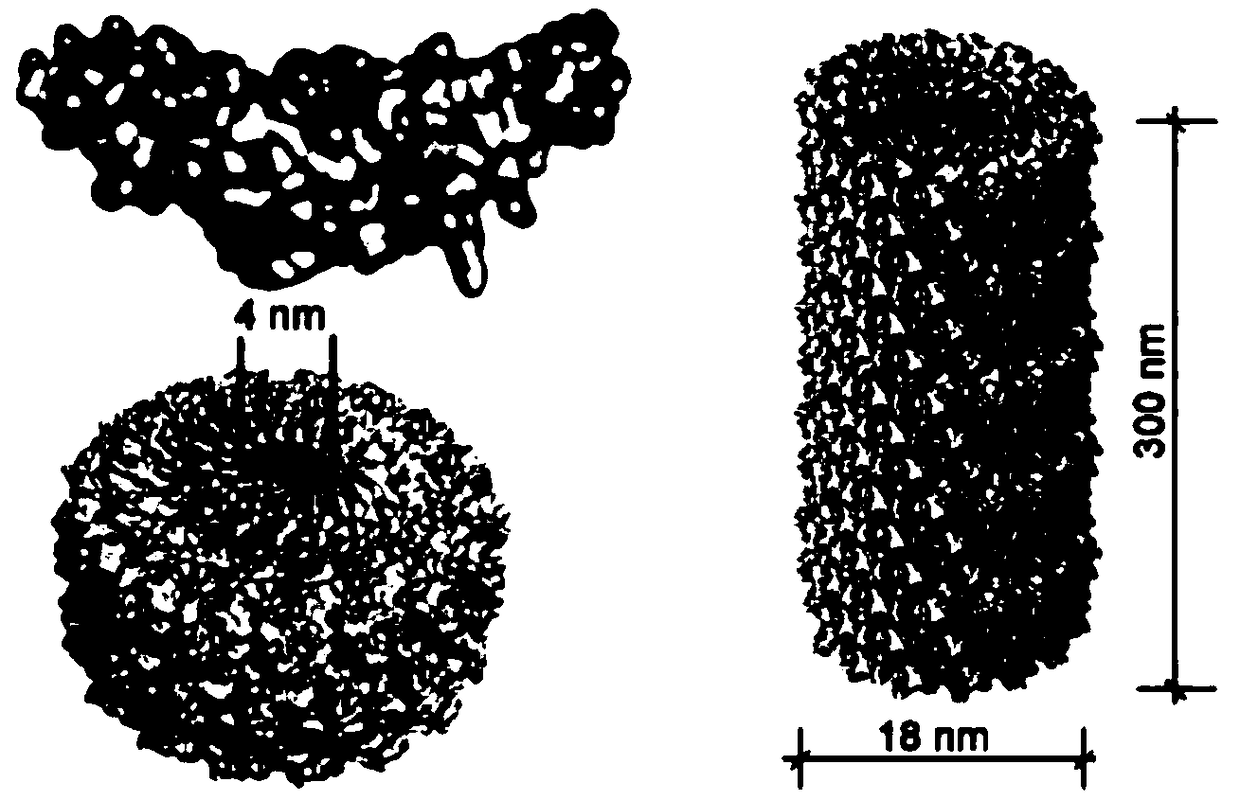

[0042] Example 1: Preparation method of piezoelectric sensor array based on tobacco mosaic virus

[0043] Step 1: Use phage display technology to obtain polypeptides and corresponding gene sequences that can specifically bind to barium titanate (BTO) piezoelectric nanoparticles

[0044] A: Take an appropriate amount of barium titanate (BTO) nanoparticle dispersion, place it in the buffer solution containing the M13 phage library, shake and mix at room temperature for 2 hours, so that the M13 phage and barium titanate nanoparticles are fully mixed;

[0045] B: centrifuge the above mixed solution for 40min at 3500rpm, remove the supernatant;

[0046] C: Rinse the precipitate 3 times with a buffer to remove the phages that are not firmly adsorbed;

[0047] D: Elute the phage that adsorbs specific functional nanoparticles, and place it in Escherichia coli culture solution for enrichment and cultivation for 30 minutes;

[0048] E: Perform high-throughput sequencing on the enriche...

Embodiment 2

[0072] Example 2: Preparation method of ammonia sensor array based on tobacco mosaic virus

[0073] Step 1: Use phage display technology to obtain a compound that can specifically bind to titanium dioxide (TiO 2 ) polypeptides of piezoelectric nanoparticles and their corresponding gene sequences

[0074] A: Take an appropriate amount of titanium dioxide (TiO 2 ) nanoparticle dispersion, which is placed in the buffer containing the M13 phage library, and shaken and mixed at room temperature for 2 hours to make the M13 phage and titanium dioxide (TiO 2 ) nanoparticles are fully mixed;

[0075] B: centrifuge the above mixed solution for 40min at 3500rpm, remove the supernatant;

[0076] C: Rinse the precipitate 3 times with a buffer to remove the phages that are not firmly adsorbed;

[0077] D: Elute the phage that adsorbs specific functional nanoparticles, and place it in Escherichia coli culture solution for enrichment and cultivation for 30 minutes;

[0078] E: Perform hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com