A method and product for preparing a lithium-ion battery ternary positive electrode material on a metal-organic framework material zif-8

A metal-organic framework, ZIF-8 technology, applied in battery electrodes, electrical components, secondary batteries, etc., to achieve the effects of simple synthesis steps, stable ternary material structure, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

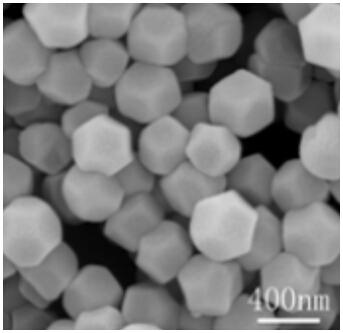

Image

Examples

preparation example Construction

[0020] 1) Preparation of metal-organic framework material ZIF-8: according to the molar ratio of zinc nitrate hexahydrate and 2-methylimidazole as 1:1~4, weigh an appropriate amount of zinc nitrate hexahydrate in a beaker, and add to the beaker 100 mL of anhydrous methanol, stirred until fully dissolved, marked as solution A; weighed an appropriate amount of 2-methylimidazole in a 200 mL beaker, and added 100 mL of anhydrous methanol, fully dissolved, marked as solution B. Quickly pour the uniformly dissolved B solution into the A solution that is being ultrasonicated, and stir for 15 min, and centrifuge the obtained milky white liquid with a desktop high-speed centrifuge to separate the product. The separated product is washed twice with water and ethanol successively, and the cleaned product is sintered in a muffle furnace at 700-900° C. for 1-5 hours.

[0021] 2) Preparation of C solution: Lithium salt, nickel salt, cobalt salt and manganese salt are synthesized according t...

Embodiment 1

[0027] ZIF-8@LiNi 0.5 co 0.2 mn 0.3 o 2 Preparation of cathode material

[0028] Weigh an appropriate amount of zinc nitrate hexahydrate in a beaker, add 100 mL of anhydrous methanol to the beaker, stir until fully dissolved, and mark it as solution A; weigh an appropriate amount of 2-methylimidazole in a 200 mL beaker, and add 100 mL of Water methanol, fully dissolved, marked as B solution. Quickly pour the uniformly dissolved B solution into the A solution that is being ultrasonicated, and stir for 15 min, and centrifuge the obtained milky white liquid with a desktop high-speed centrifuge to separate the product. After separating the product, the product was successively washed twice with water and ethanol. The cleaned product was sintered in a muffle furnace at 700°C for 2h. Lithium salt, nickel salt, cobalt salt and manganese salt were synthesized according to LiNi 0.5 co 0.2 mn 0.3 o 2Calculate the amount of material used. A solution was prepared by dissolving ...

Embodiment 2

[0030] ZIF-8@LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of cathode material

[0031] Weigh an appropriate amount of zinc nitrate hexahydrate in a beaker, add 100 mL of anhydrous methanol to the beaker, stir until fully dissolved, and mark it as solution A; weigh an appropriate amount of 2-methylimidazole in a 200 mL beaker, and add 100 mL of Water methanol, fully dissolved, marked as B solution. Quickly pour the uniformly dissolved B solution into the A solution that is being ultrasonicated, and stir for 15 min, and centrifuge the obtained milky white liquid with a desktop high-speed centrifuge to separate the product. After separating the product, the product was successively washed twice with water and ethanol. The cleaned product was sintered in a muffle furnace at 700°C for 2h. Lithium salt, nickel salt, cobalt salt and manganese salt were synthesized according to LiNi 0.6 co 0.2 mn 0.6 o 2 Calculate the amount of material used. A solution was prepared by dissolving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com