A proton exchange membrane fuel cell unit, a fuel cell stack, an assembly process and a control method

A fuel cell unit and proton exchange membrane technology, which is applied to fuel cells, fuel cell parts, electrical components, etc., can solve the problems of high technical requirements for assembly processes, unsuitable for large-scale production, and high engineering difficulties. The effect of solving electrochemical corrosion, overcoming corrosion problems, and simplifying assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

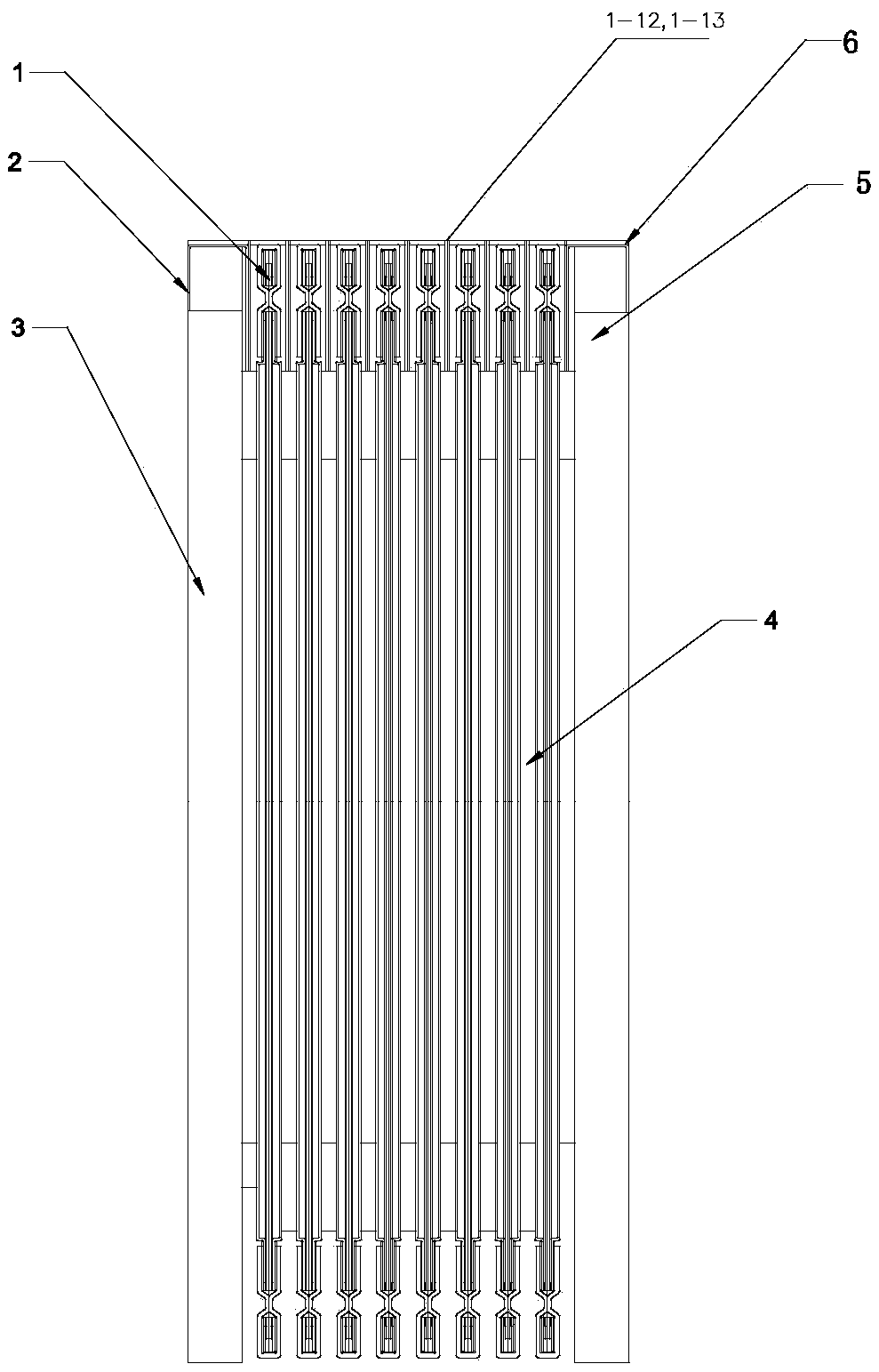

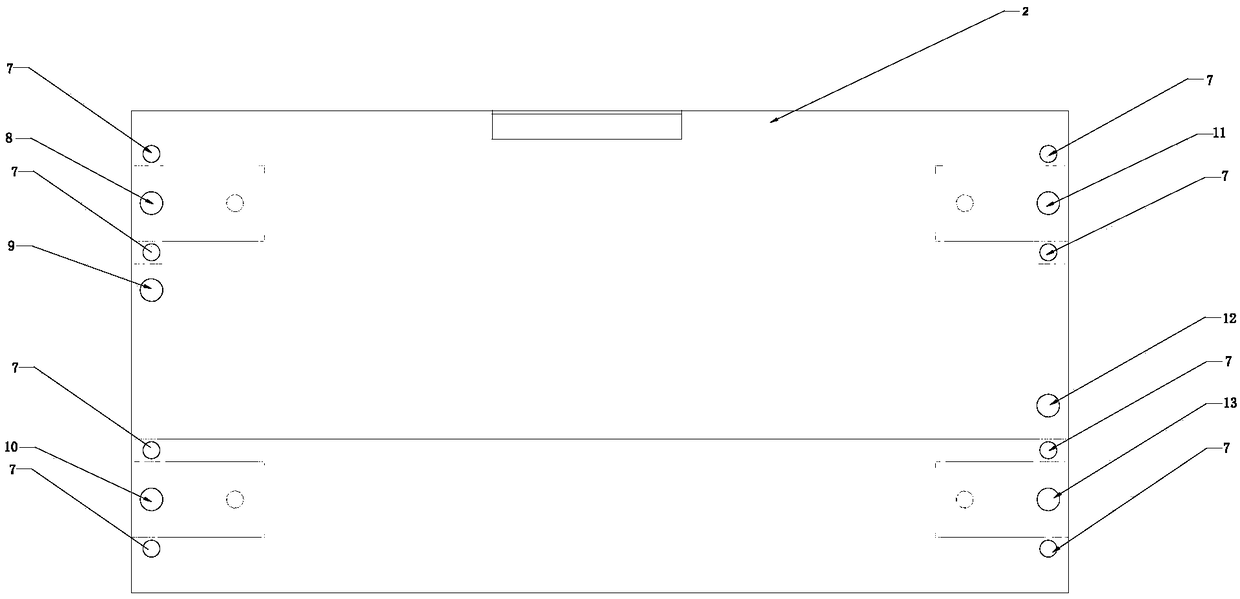

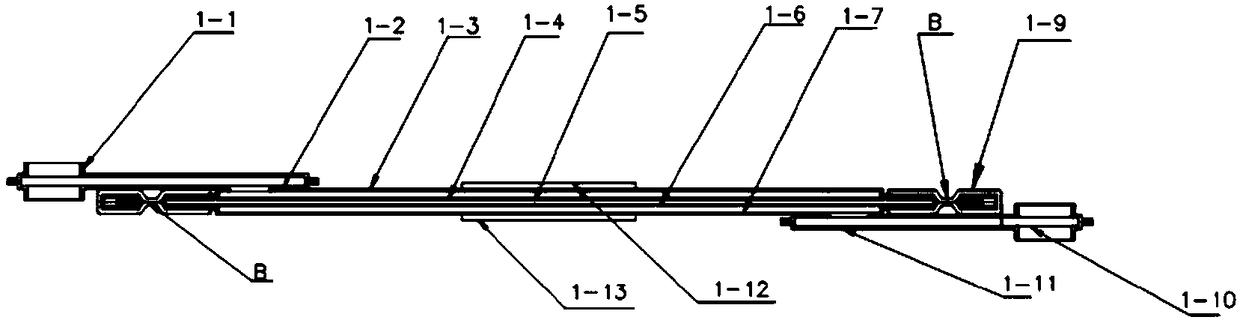

[0031] figure 1 It is a schematic cross-sectional view of a fuel cell stack of the present invention. figure 2 It is a schematic front view of a fuel cell stack of the present invention. image 3 It is a schematic side view of the composition structure of a fuel cell unit of the present invention. Figure 4 It is a schematic front view of the composition structure of a fuel cell unit of the present invention. Figure 5 It is a structural explosion diagram of a fuel cell unit of the present invention. In the drawings, the reference signs are as follows: 1 is the fuel cell unit, 2 is the positive terminal, 3 is the first end plate, 4 is the liquid cooling plate, 5 is the second end plate, 6 is the negative terminal, 7 is Battery stack fastening bolts, 8 is the hydrogen inlet, 9 is the coolant outlet, 10 is the hydrogen outlet, 11 is the oxygen inlet, 12 is the coolant inlet, and 13 is the oxygen outlet. 1-1, 1-2 are hydrogen distributors, 1-3 are negative (hydrogen) flow fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com