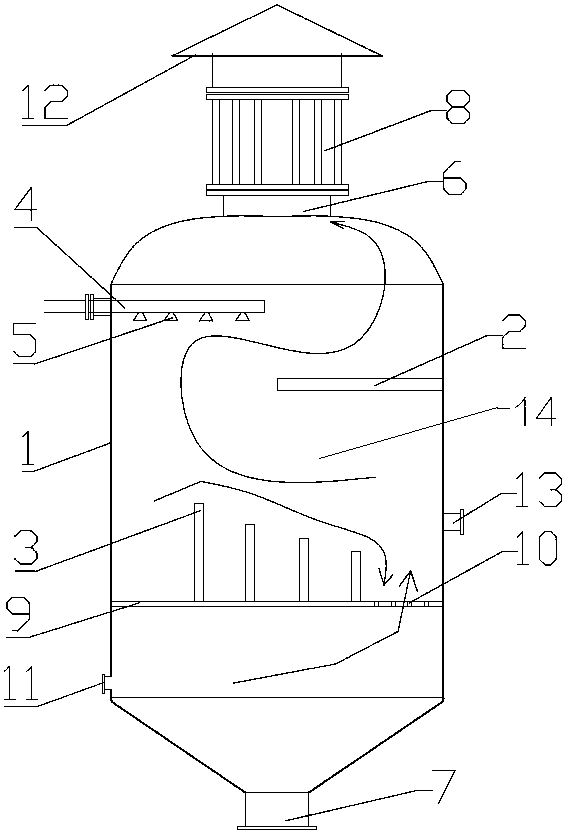

Method and device for removing hydrogen sulfide in waste gas through continuous oxidation

A hydrogen sulfide and exhaust gas technology, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problems of low hydrogen sulfide absorption efficiency, inability to effectively remove or recover hydrogen sulfide, and inability to guarantee hydrogen sulfide and injection The full contact of the spraying liquid and other issues can achieve the effect of facilitating liquid and gas convection exchange, increasing the treatment effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

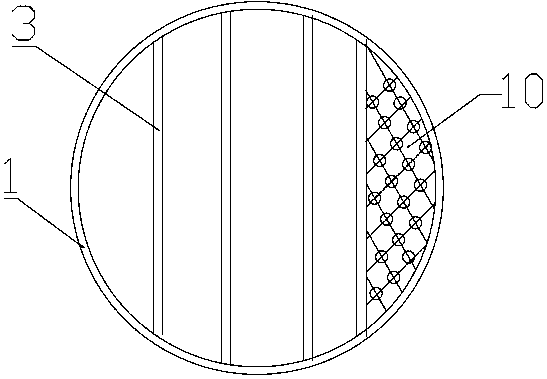

[0046] A method for removing hydrogen sulfide in waste gas based on continuous oxidation, comprising the steps of:

[0047] A. The exhaust gas containing hydrogen sulfide passes through the blower on the exhaust gas delivery pipe, and the air volume is 19800m 3 / h, wind pressure is 7800pa and temperature is 20 DEG C and is transported in the tank body 1;

[0048] After the exhaust gas containing hydrogen sulfide enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0049] B. The spray pipe 4 sprays the atomized oxidant into the through cavity 14 of the tank body 1 through the atomizing nozzle 5, and after the oxidant enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0050] The oxidizing agent has a temperature of 30°C and a flow rate of 180m 3 / h and a pressure of 0.2Mpa into the through cavity 14 of the tank body 1;

[0051] C. The exhaust gas containing hydrogen sulfide in step A is contacted with the at...

Embodiment 2

[0057] A method for removing hydrogen sulfide in waste gas based on continuous oxidation, comprising the steps of:

[0058] A. The exhaust gas containing hydrogen sulfide passes through the blower on the exhaust gas delivery pipe, and the air volume is 20000m 3 / h, wind pressure is 8000pa and temperature is 30 DEG C and is transported in the tank body 1;

[0059] After the exhaust gas containing hydrogen sulfide enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0060] B. The spray pipe 4 sprays the atomized oxidant into the through cavity 14 of the tank body 1 through the atomizing nozzle 5, and after the oxidant enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0061] The oxidizing agent has a temperature of 35°C and a flow rate of 210m 3 / h and a pressure of 0.3Mpa into the through cavity 14 of the tank body 1;

[0062] C. The exhaust gas containing hydrogen sulfide in step A is contacted with the at...

Embodiment 3

[0068] A method for removing hydrogen sulfide in waste gas based on continuous oxidation, comprising the steps of:

[0069] A. The exhaust gas containing hydrogen sulfide passes through the blower on the exhaust gas delivery pipe, and the air volume is 19900m 3 / h, wind pressure is 7900pa and temperature is that 25 ℃ are transported in the tank body 1;

[0070] After the exhaust gas containing hydrogen sulfide enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0071] B. The spray pipe 4 sprays the atomized oxidant into the through cavity 14 of the tank body 1 through the atomizing nozzle 5, and after the oxidant enters the tank body 1, it diffuses into the through cavity 14 of the tank body 1;

[0072] The oxidizing agent has a temperature of 33°C and a flow rate of 195m 3 / h and a pressure of 0.25Mpa into the through cavity 14 of the tank body 1;

[0073] C. The exhaust gas containing hydrogen sulfide in step A contacts the atomized oxi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap