Preparation method for bis-fluorosulfonyl imide compound

A technology of bisfluorosulfonimides and compounds, which is applied in the field of preparation of bisfluorosulfonimides, can solve the problems of unfavorable wide application, high purification cost, and large passivation film resistance, and achieve the requirements of undemanding operating equipment, Easy separation and purification, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

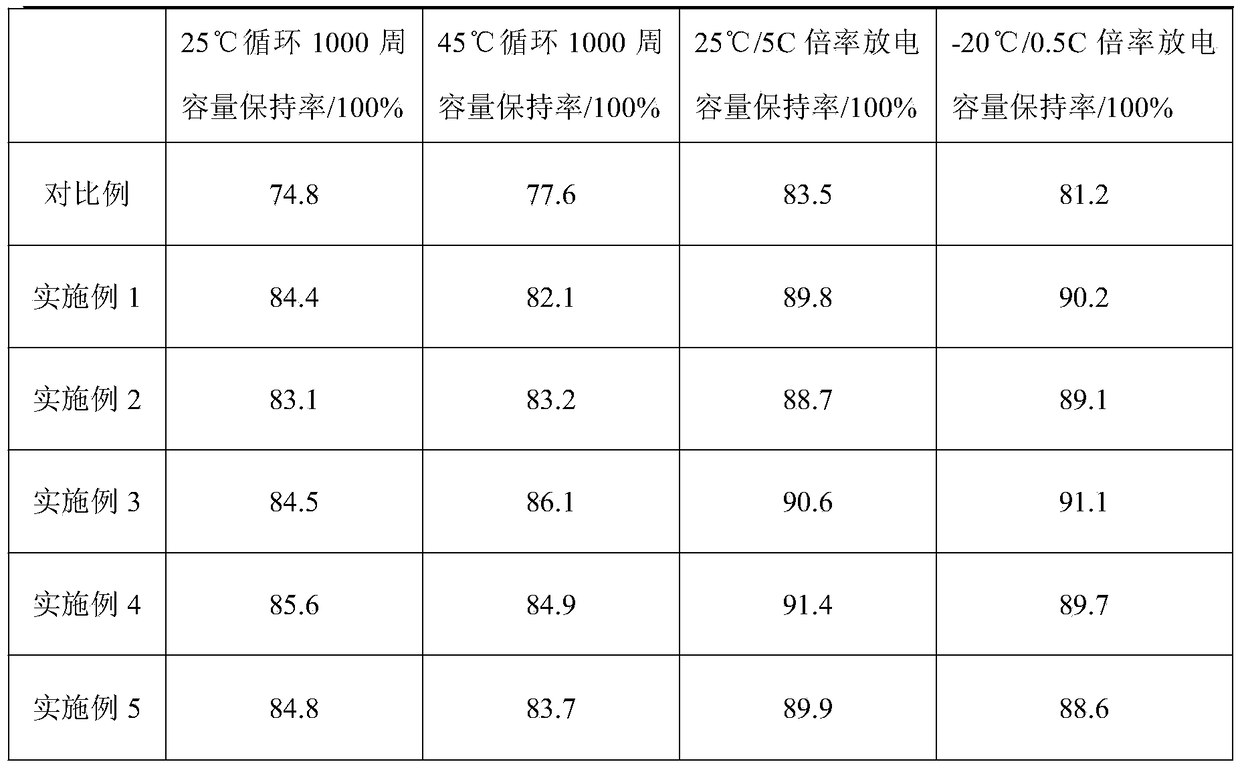

Examples

preparation example Construction

[0021] A preparation method of bisfluorosulfonyl imides, the preparation method comprising the following steps:

[0022] (1) the FSO 2 X, nitrogen source, acid-binding agent and aprotic solvent are mixed to obtain a mixture; wherein, the nitrogen source is a primary amine, and the acid-binding agent is an aprotic organic amine; the acid-binding agent and FSO 2 The molar ratio of X is 1:2~5; the molar ratio of nitrogen source and acid-binding agent is 1:3~8; the X is F or C n f 2n+1 , n=1-5;

[0023] (2) Heat the mixture to reflux and react for 12h to 72h;

[0024] (3) After the reflux reaction is finished, cool down, release the pressure, spin dry the solvent, add water to wash and filter, and obtain the crude product;

[0025] (4) Recrystallize the crude product to obtain finished products of bisfluorosulfonimide compounds.

[0026] The acid-binding agent is at least one of triethylamine, tetramethylethylenediamine and tetramethyl-1,3-propylenediamine.

[0027] The apro...

Embodiment 1

[0037] (1) Add 200g acetonitrile and 150.2g triethylamine in 1L autoclave, add 45.9g aniline, slowly add 100g sulfuryl fluoride (F 2 SO 2 ) mixed to obtain a mixture; aniline, F 2 SO 2 The molar ratio to triethylamine is 1:2:3; heat the autoclave to 80°C, and continue to stir and reflux for 36 hours; then cool to normal temperature, wash and extract to obtain the filtrate; use a rotary evaporator to remove the The solvent was distilled off to obtain a crude product, which was put into an oven to heat and vacuum-dry to obtain the final product, weighing 110 g, with a yield of 87%.

[0038] (2) The final product can be further purified to obtain bisfluorosulfonimide compounds with a purity greater than 99%. The specific steps are as follows: 110 g of the final product is stirred and dissolved with 220 g of methanol, allowed to stand at -24°C for 24 hours, and filtered , the obtained solid precipitate was put into an oven for vacuum drying to obtain purified N-phenylbisfluoros...

Embodiment 2

[0042] (1) Add 300g dichloromethane and 145.2g tetramethylethylenediamine in 1L autoclave, add 40g 2-aminopyridine, slowly add 85g sulfonyl fluoride (F 2 SO 2 ) mixed to obtain a mixture; 2-aminopyridine, F 2 SO2 The molar ratio to tetramethylethylenediamine is 1:2:3; heat the autoclave, raise the temperature to 40°C, and continue to stir and reflux for 36 hours; then cool to normal temperature, wash and extract to obtain the filtrate; use a rotary evaporator to The solvent in the filtrate was distilled off to obtain a crude product, which was put into an oven, heated and dried under vacuum to obtain the final product, weighing 96 g, with a yield of 89%.

[0043] (2) The final product can be further purified to obtain a bisfluorosulfonimide compound with a purity greater than 99%. The specific steps are as follows: stir and dissolve the final product with 192 g of methanol and 96 g of the final product, stand at -24°C for 36 hours, and filter. The obtained solid precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com