Improved biogas slurry ecological treatment and cultivation system

An ecological treatment and breeding system technology, applied in the direction of biological water/sewage treatment, sedimentation treatment, special treatment objectives, etc., can solve the problems of high operating cost, less biogas slurry usage, and not very obvious removal effect, so as to reduce environmental pollution. Pollution, solving cost problems, optimizing water quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

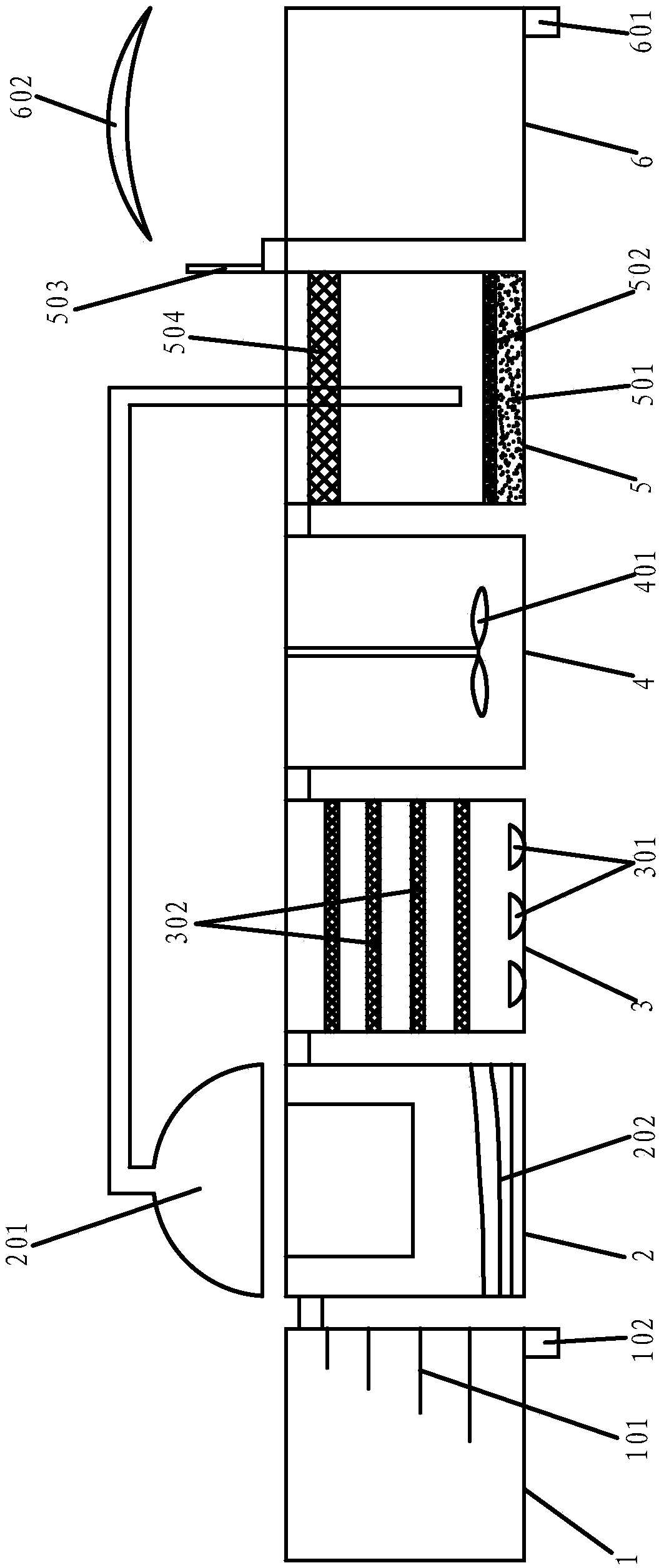

[0035] Such as figure 1 As shown, the biogas slurry ecological treatment breeding system includes solid-liquid separation tank 1, decomposition treatment tank 2, aeration treatment tank 3, acid-base adjustment tank 4, algae cultivation tank 5 and animal cultivation tank 6 arranged in the order of treatment process , the solid-liquid separation pool 1, the decomposition treatment pool 2, the aeration treatment pool 3, the acid-base adjustment pool 4, the algae culture pool 5 and the animal culture pool 6 are connected end-to-end in series through the connection port; the top of the solid-liquid separation pool 1 is set The poultry house is used to breed poultry in the poultry house. The bottom of the poultry house is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com