Preparation method for water-soluble natural vitamin E

A natural vitamin, water-soluble technology, applied in the field of preparation of water-soluble natural vitamin E, can solve the problems of inability to prepare high-purity TPGS, large separation loss of separation means, unclean separation of impurities, etc., and achieves easy automatic operation and simplified reaction. Post-processing operations to achieve the effect of automated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

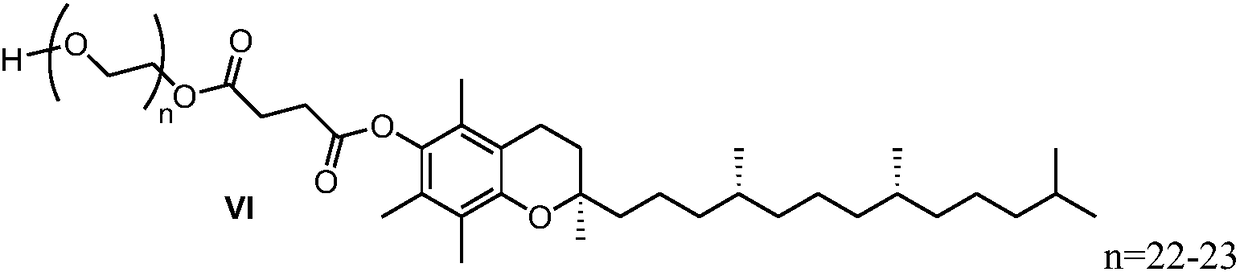

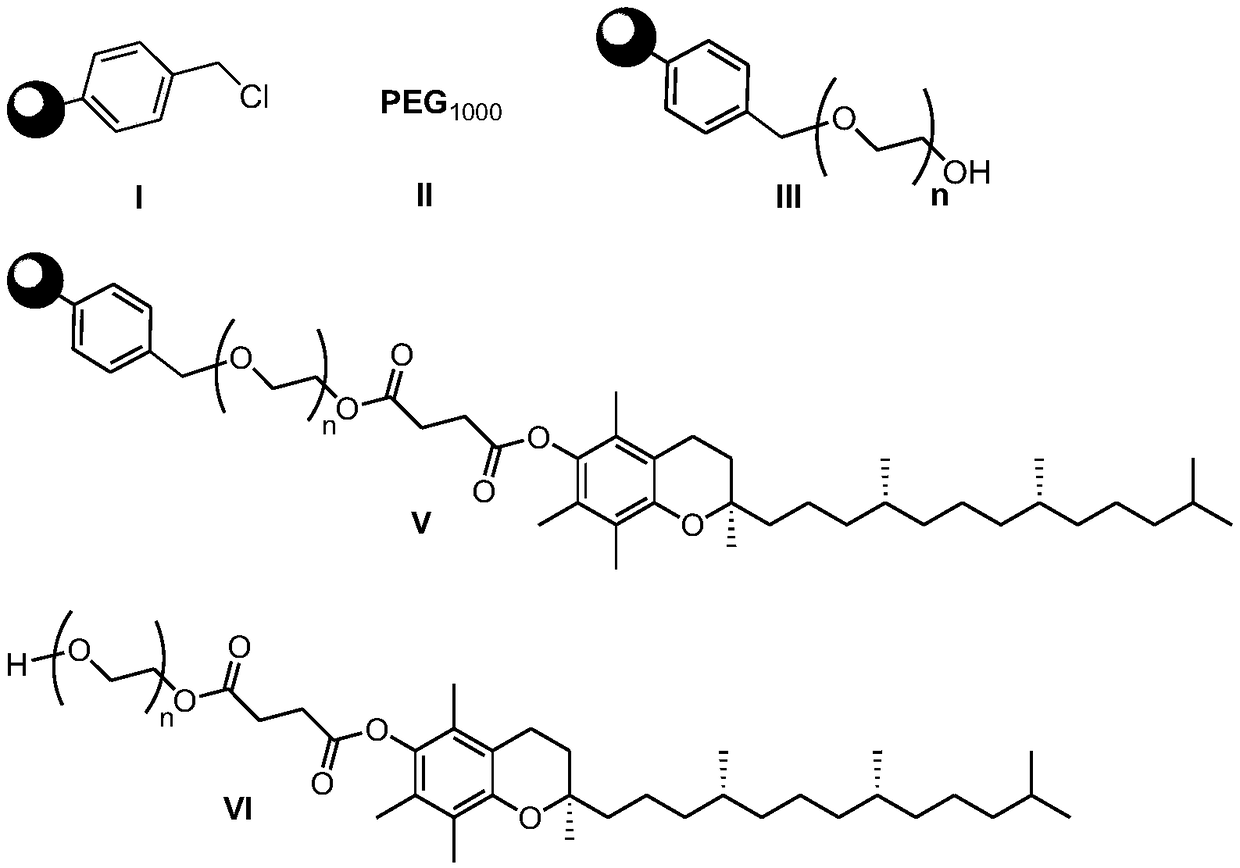

[0045] Embodiment 1: the preparation of water-soluble natural vitamin E (TPGS) shown in formula VI

[0046] (1) Preparation of unidirectional loaded PEG1000 resin III

[0047] The reaction formula is as follows:

[0048]

[0049] Add PEG1000II (44g, 44mmol) and 5mL toluene into the reaction flask, heat to 50°C, start stirring, after the PEG1000 melts, add catalyst sodium ethoxide (2.994g, 44mmol) in batches, heat up to 85°C for 1 hour. Add chloromethyl polystyrene resin I (10 g, 1.1 mmol / g chlorine load) successively with tetrahydrofuran (THF) and toluene soaked and swollen for 3 hours in four batches, and then heat up to 130 ° C to continue the reaction for 5 Hour. Stop the reaction, and when the temperature drops to 80°C, filter while it is hot. The filtrate is transferred to a clean container and stored in a sealed container, which can be used in the next similar reaction; the filter cake is washed in the following order: water (100mL×2 times), THF (50mL×1 time), THF / ...

Embodiment 2

[0065] Embodiment 2: the Merrifield resin of different chlorine loads prepares TPGS

[0066]

[0067] (1) The first step reaction: preparation of unidirectional loaded PEG1000 resin III

[0068] Add PEG1000II (4×10×Y g, 4×10×Ymmol, Y is the amount of chlorine loaded on chloromethyl polystyrene resin Ⅰ, the same below) and 5×Y mL toluene into the reaction bottle, heat to 45°C, turn on Stir, after the PEG1000 is melted, add the catalyst sodium ethoxide (4×10×Ymmol) in batches, raise the temperature to 80° C. and react for 1 hour. Then add chloromethyl polystyrene resin I (10 g, Y mmol / g chlorine loading) successively with tetrahydrofuran (THF) and toluene soaked for 3 hours in 4 batches, then raise the temperature to 130 ° C and continue the reaction for 5 hours . Stop the reaction, and when the temperature drops to 80°C, filter while it is hot. The filtrate is transferred to a clean container and stored in a sealed container, which can be used in the next similar reaction...

Embodiment 3

[0075] Embodiment 3 Resin V cleavage reaction prepares TPGS

[0076] The reaction formula is as follows:

[0077]

[0078] Method a: in an autoclave, add the load TPGS resin V (TPGS loading capacity is 0.414mmol / g) and a certain amount of solvent (see Table 2) prepared by step (2) in 5.0g embodiment 1, soak for 6 hours, and then Add a certain amount of palladium carbon (5wt%, that is, the Pd / C with a weight content of 5%) and a certain amount of additives (see Table 2), seal the autoclave, and replace it with nitrogen and hydrogen successively (i.e. into the autoclave). Fill the corresponding gas to 0.5MPa and then vent) 3 times. Fill the autoclave with hydrogen at a certain pressure, raise the temperature and stir to react. The following operations are the same as step (3) of Example 1 to finally obtain TPGS VI, as shown in Table 2.

[0079] Method b: in the reaction flask, add the load TPGS resin V (TPGS load is 0.414mmol / g) and a certain amount of solvent (see Table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com