A kind of waterproof polyurethane coating for zipper and preparation method thereof

A polyurethane coating, polyurethane prepolymer technology, applied in the direction of coating, can solve the problems of coating stretchability, poor toughness, zipper not having washability, affecting clothing texture, etc., to improve mechanical properties and waterproof. properties, improving cross-linking stability, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for a waterproof polyurethane coating material for slide fasteners, comprising the steps of:

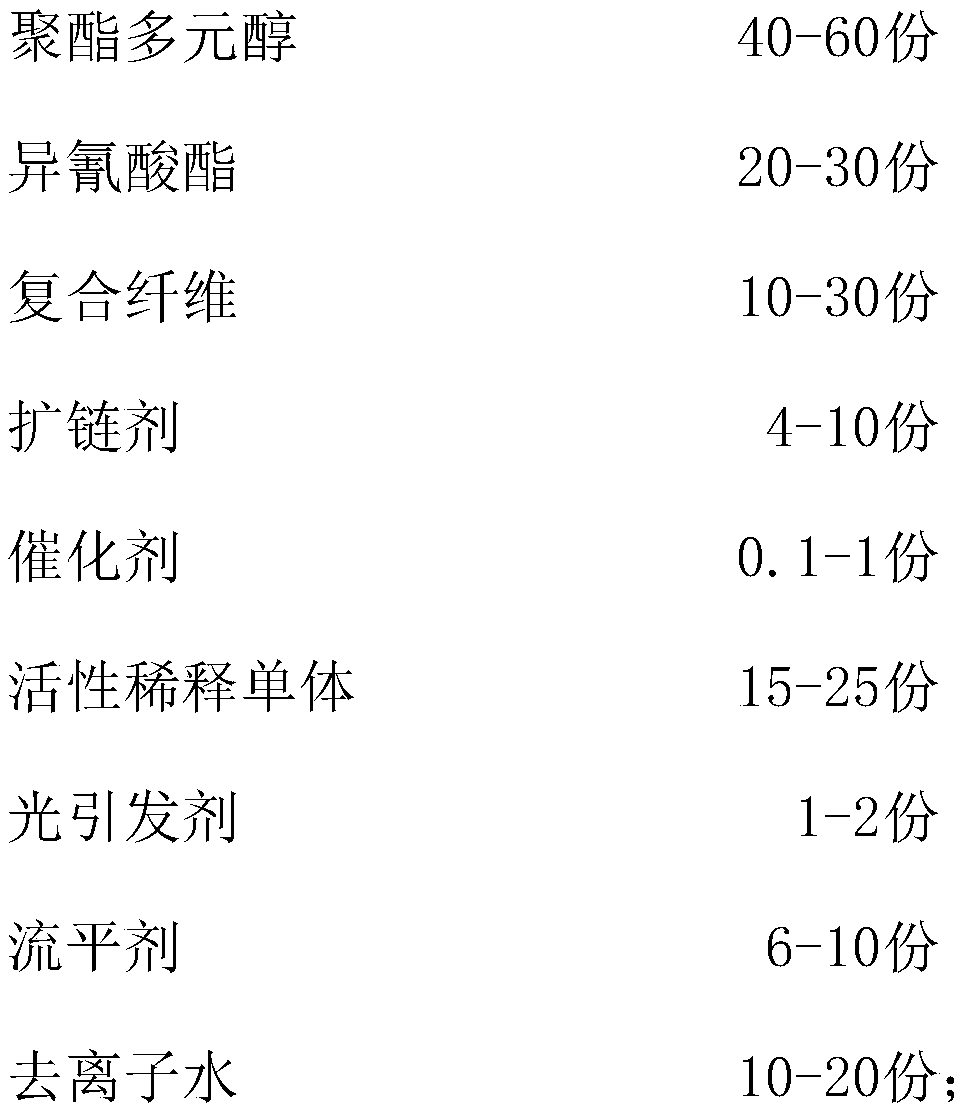

[0033](1) Preparation of polyurethane prepolymer: 50 parts by weight of polyether polyol, 0.5 parts by weight of catalyst, and 25 parts by weight of isocyanate are mixed, and the temperature is raised to 60° C. to obtain a mixed solution, and 7.5 parts by weight of composite fibers are added to the mixed solution. and 7 parts by weight of chain extender, heat up to 75°C, and react for 5.2h to obtain a polyurethane prepolymer;

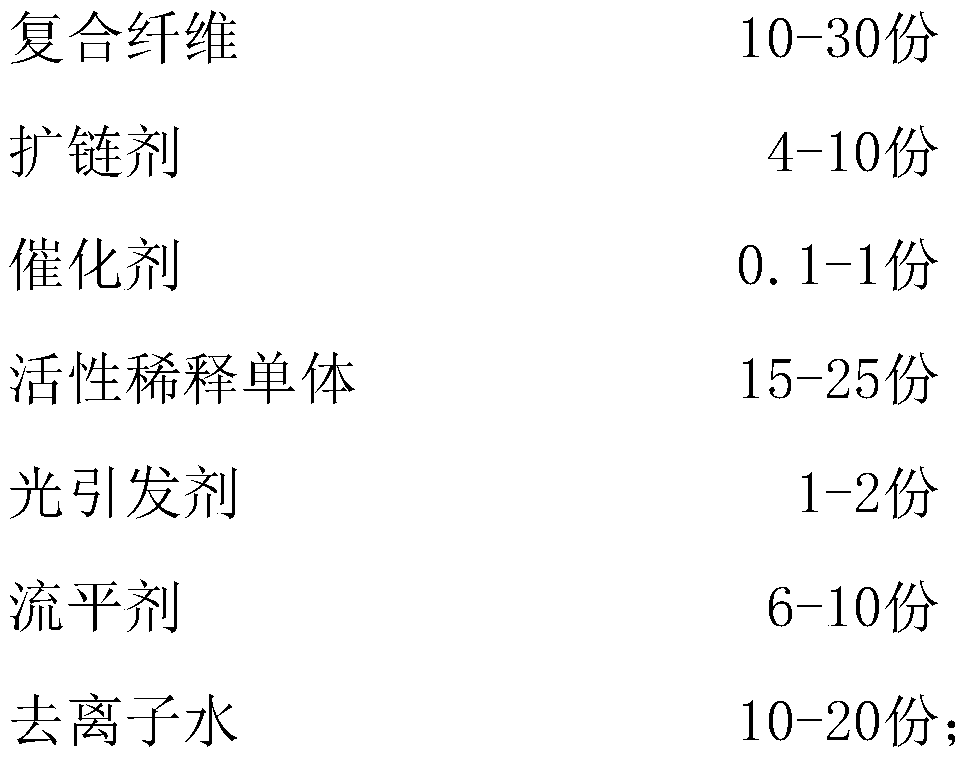

[0034] (2) Preparation of coating: adding 12.5 parts by weight of composite fibers, 20 parts by weight of reactive diluent monomers, 0.5 parts by weight of photoinitiator and the polyurethane prepolymer obtained in step (1) into 15 parts by weight of deionized water, After stirring at 1300 rpm for 12.5 minutes, 8 parts by weight of a leveling agent was added, and the mixture was stirred at 500 rpm for 7 minutes to obtain the waterpr...

Embodiment 2

[0045] A preparation method of a waterproof polyurethane coating material for a zipper, comprising the following steps:

[0046] (1) Preparation of polyurethane prepolymer: 40 parts by weight of polyether polyol, 0.1 part by weight of catalyst, and 20 parts by weight of isocyanate were mixed, and the temperature was raised to 50° C. to obtain a mixed solution, and 5 parts by weight of composite fibers were added to the mixed solution. and 4 parts by weight of chain extender, heat up to 70°C, and react for 3.5h to obtain a polyurethane prepolymer;

[0047] (2) Preparation of coating: adding 5 parts by weight of composite fibers, 15 parts by weight of reactive diluent monomers, 1 part by weight of photoinitiator and the polyurethane prepolymer obtained in step (1) into 10 parts by weight of deionized water, After stirring at 1200 rpm for 10 min, 6 parts by weight of leveling agent were added, and the mixture was stirred at 400 rpm for 4 min to obtain the waterproof polyurethane ...

Embodiment 3

[0058] A preparation method of a waterproof polyurethane coating material for a zipper, comprising the following steps:

[0059] (1) Preparation of polyurethane prepolymer: 60 parts by weight of polyether polyol, 1 part by weight of catalyst, and 30 parts by weight of isocyanate are mixed, and the temperature is raised to 70° C. to obtain a mixed solution, and 10 parts by weight of composite fibers are added to the mixed solution. and 10 parts by weight of chain extender, heat up to 80 ° C, and react for 7 h to obtain a polyurethane prepolymer;

[0060] (2) Preparation of coating: adding 20 parts by weight of composite fibers, 25 parts by weight of reactive diluent monomers, 2 parts by weight of photoinitiator and the polyurethane prepolymer obtained in step (1) into 20 parts by weight of deionized water, After stirring at 1400rpm for 15min, 10 parts by weight of leveling agent was added, and the mixture was stirred at 600rpm for 10min to obtain the waterproof polyurethane coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com