Low VOC waterborne polyurethane floor paint and preparation method thereof

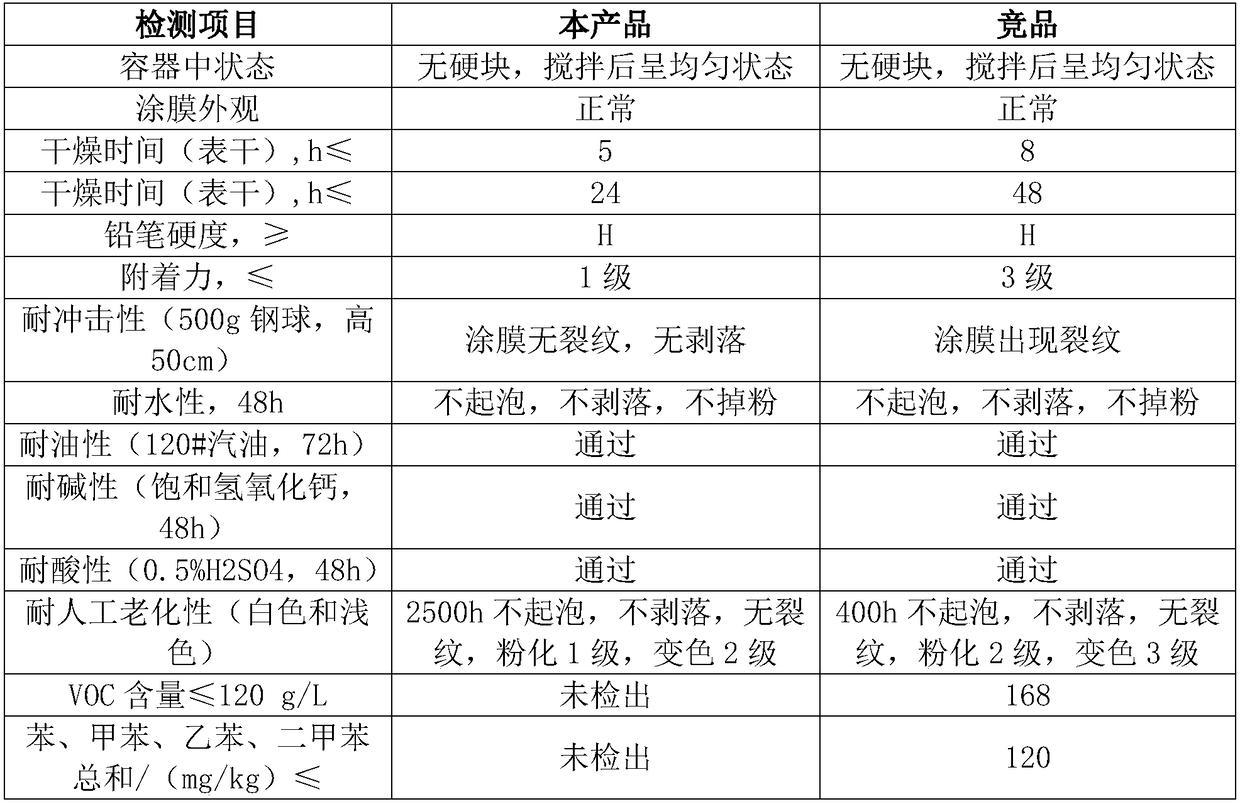

A water-based polyurethane and floor coating technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of unsafe, high VOC content, not environmental protection, etc., and achieve excellent performance, low VOC, resistance to The effect of acid and alkali resistance to chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of low VOC waterborne polyurethane floor coating of the present invention, it may further comprise the steps:

[0035] A pre-mixing stage: Add pure water, start the disperser, adjust the speed to 500r / min, add wetting dispersant, and pH regulator, stir for 3 minutes, then add thickener, stir for 3 minutes, and confirm that the solution is slurry Finally, adjust the rotating speed to 1200r / min, and then add the pigment rutile titanium dioxide (preferably imported rutile titanium dioxide R706, Table 1 takes imported rutile titanium dioxide R706 as an example), and under the condition that the powder does not accumulate, Adjust the rotation speed to 1500r / min, disperse at high speed for 15 minutes, take a sample and add the emulsion to test the fineness, when the particle size is below 50μm, it can be thinned;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com