Radiant syngas cooler for entrained-flow bed gasification and cooling method

An entrained flow bed and waste boiler technology, which is applied in gasification process, granular/powder fuel gasification, production of combustible gas, etc., can solve problems such as unreasonable setting of fin water-cooling wall, affecting heat transfer effect, and massive deposition of particles. , to improve the local heat transfer effect, optimize the flow field structure, and reduce the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Radiation waste pot

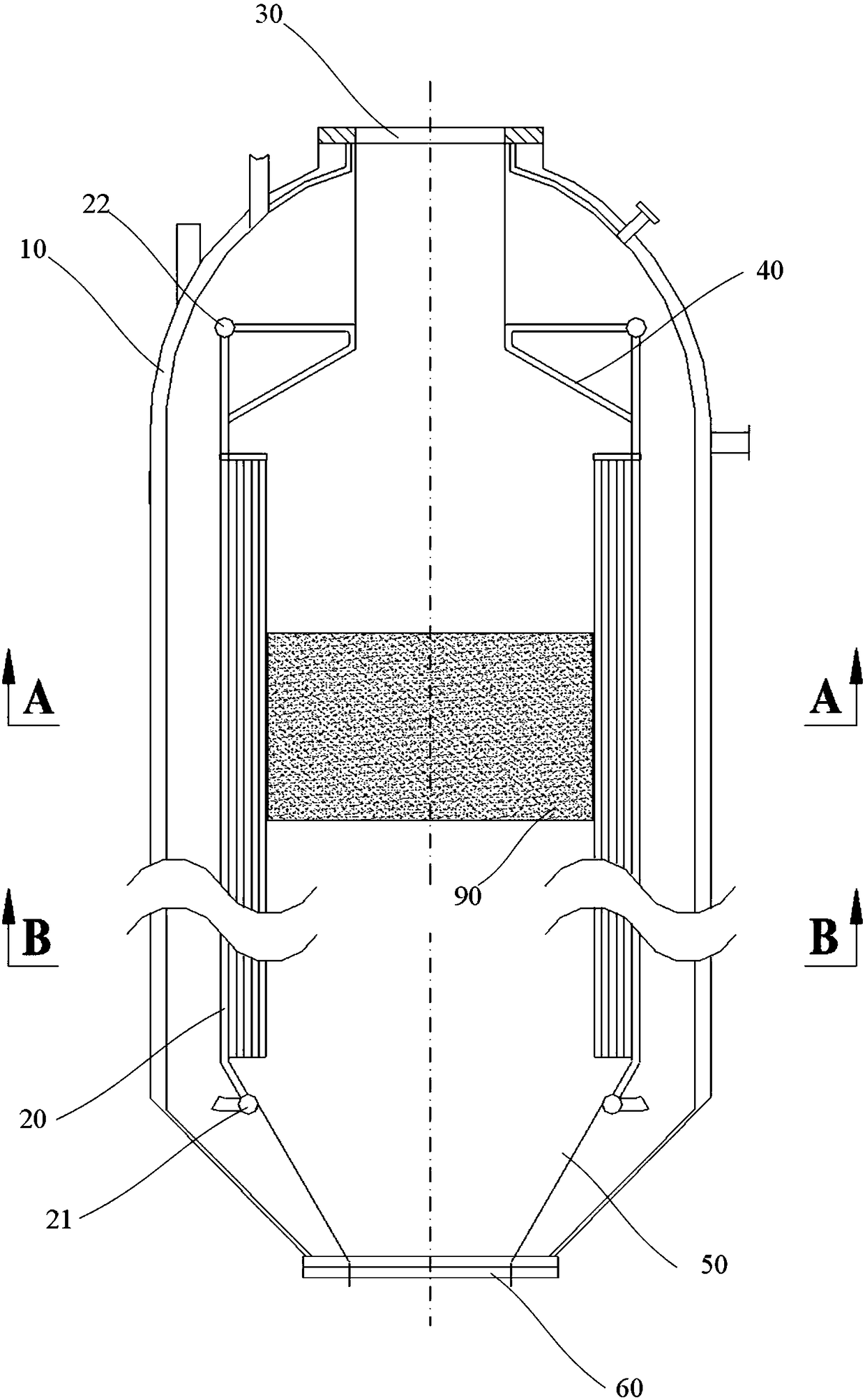

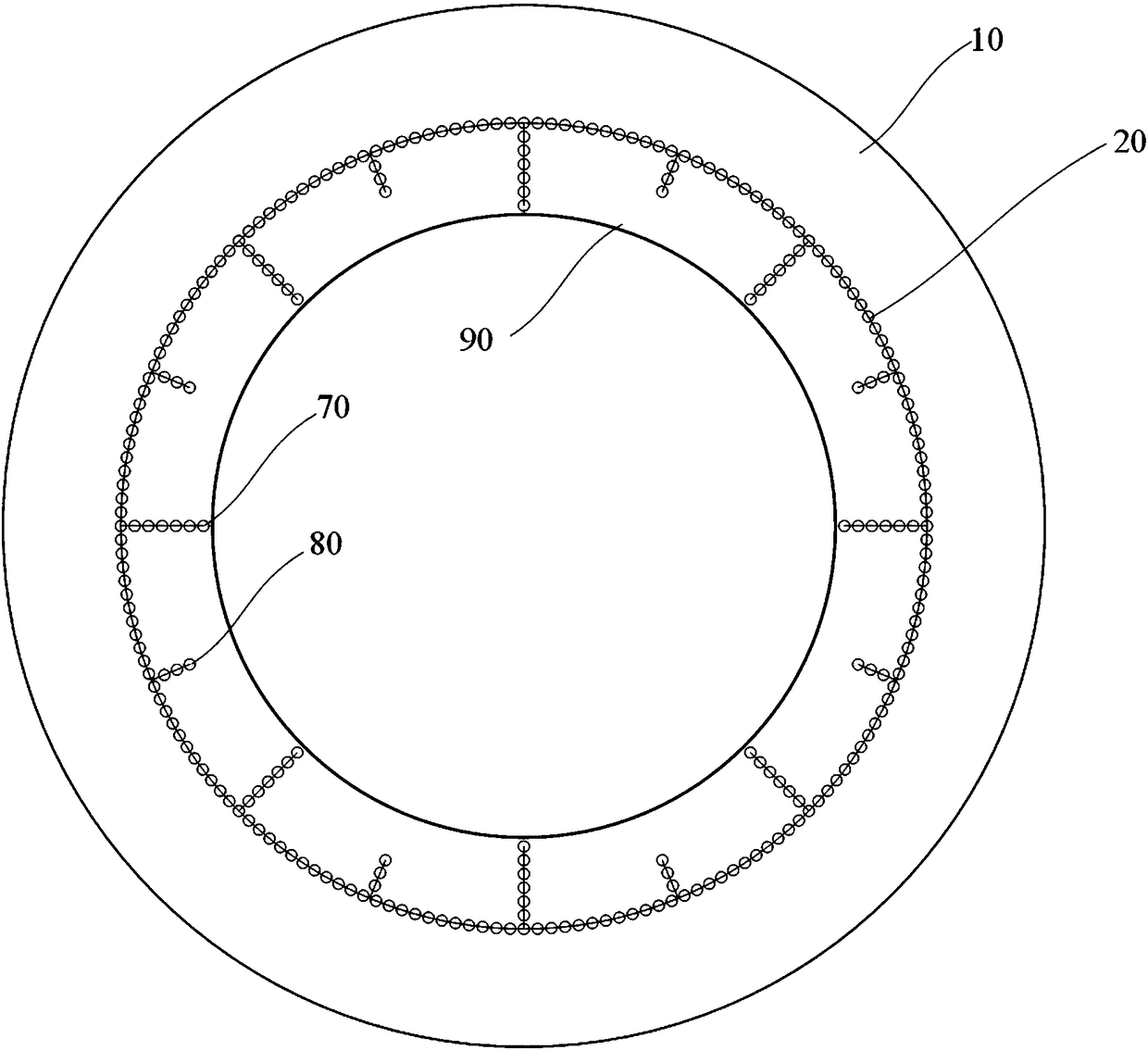

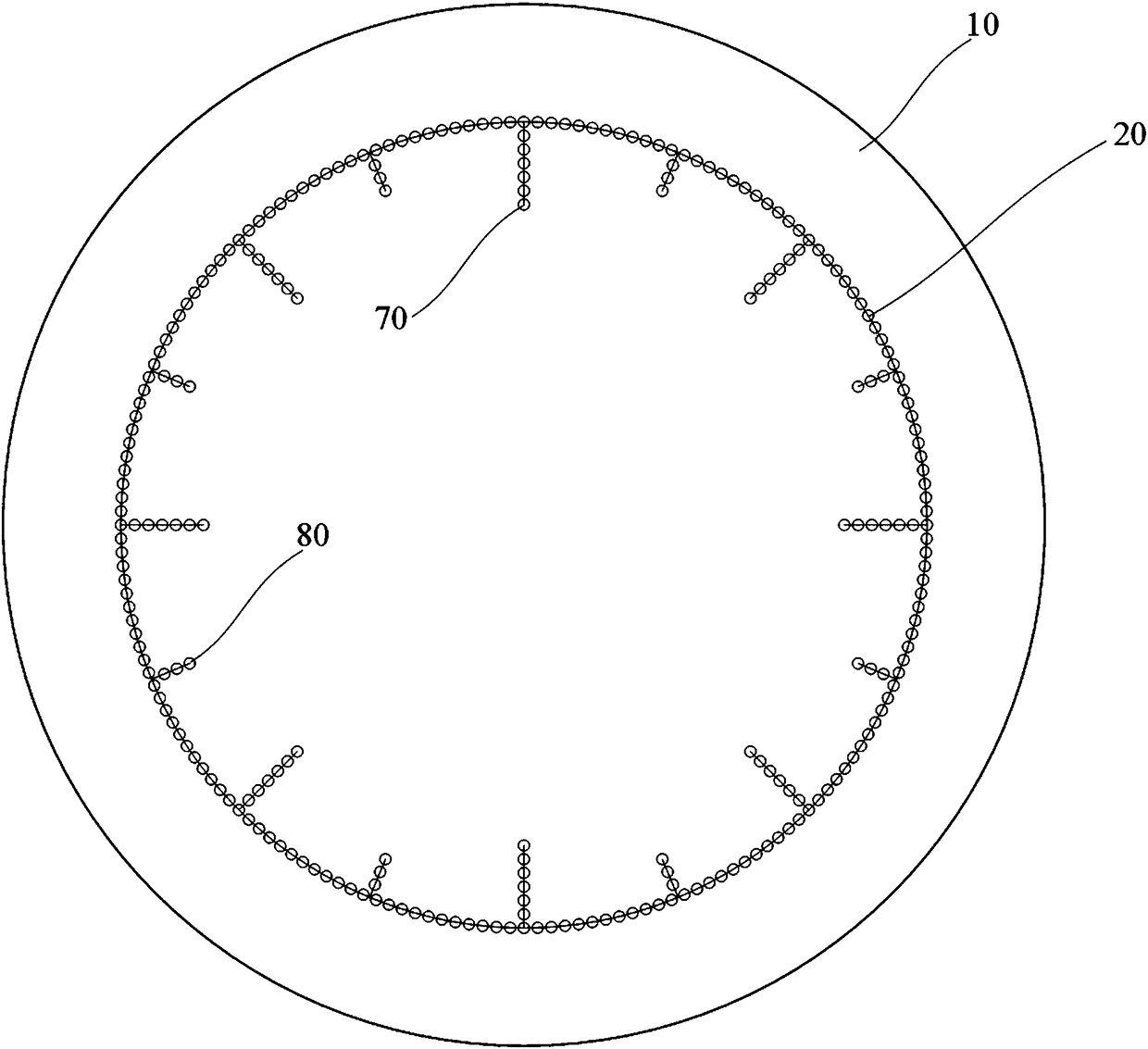

[0064] like figure 1 As shown in the radiation waste pot, the radiation waste pot has a metal shell 10 that can withstand a high pressure of no more than 10 MPa, and a cylindrical water-cooled wall 20 is provided inside. The radiation waste boiler inlet 30 is set on the top with a diameter of 1.5m, and it is connected with the high-temperature synthesis gas outlet of the gasifier. Below the radiation waste boiler inlet 30 is a radiation waste boiler interface 40 with a flared structure. The cylinder water cooling wall 20 is a cylinder structure surrounded by a circle of tubular water cooling tubes and the fins in the middle. The water supply inlet 21 of the cylinder water cooling wall 20 is located at the bottom of the cylinder water cooling wall 20. The cylinder water cooling wall The steam-water mixture outlet 22 of 20 is arranged on the top of the cylinder water wall 20, and the diameter of the cylinder water wall 20 is 3.2m.

[0065] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com