Water-repellent oil-proof anti-static dust collecting bag material

A water-repellent, oil-repellent, anti-static technology, applied in the manufacture of conductive/antistatic filaments, conjugated synthetic polymer rayon, textiles and papermaking, etc. , good friction resistance, excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

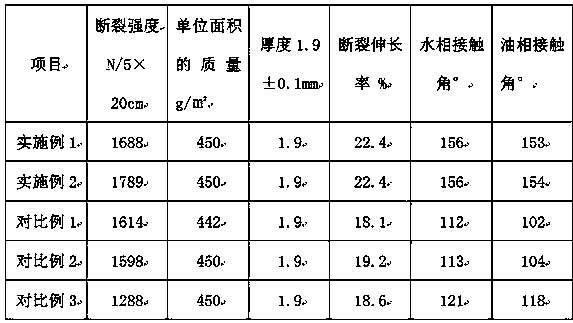

Examples

Embodiment 1

[0015] A water-repellent, oil-repellent, antistatic and dust-removing cloth bag material, comprising the following components: 80 parts of polyphenylene sulfide sulfone, 100 parts of soluble polytetrafluoroethylene, 20 parts of modified polyester, 2 parts of carbon nanotubes, chlorinated polytetrafluoroethylene 30 parts of ether, 5 parts of carbon fiber, 3 parts of silicon carbide short fiber, 1 part of calcium sulfate whisker, 2 parts of ion-modified clay, 1 part of coupling agent, 2 parts of antistatic agent, 2 parts of antiaging agent, water repellent 1 part of oil agent, 1 part of cleaning additive.

[0016] Further, the water and oil repellent agent is made by uniformly mixing fluorine-containing compound and alcohol in a weight ratio of 1:80~1:60, wherein the fluorine-containing compound is 1H, 1H, 2H, 2H-perfluorododecanethiol, One or more of heptafluorodecyltriethoxysilane and tridecafluorooctyltriethoxysilane.

[0017] Further, the cleaning additive is composed of 1 ...

Embodiment 2

[0021] A water-repellent, oil-proof, anti-static and dust-removing cloth bag material, comprising the following components: 80 parts of polyphenylene sulfide sulfone, 50 parts of soluble polytetrafluoroethylene, 20 parts of modified polyester, 2 parts of carbon nanotubes, chlorinated polytetrafluoroethylene 20 parts of ether, 5 parts of carbon fiber, 3 parts of silicon carbide short fiber, 1 part of calcium sulfate whisker, 2 parts of ion-modified clay, 1 part of coupling agent, 2 parts of antistatic agent, 2 parts of antiaging agent, water repellent 1 part of oil agent, 1 part of cleaning additive.

[0022] Further, the water and oil repellent agent is made by uniformly mixing fluorine-containing compound and alcohol in a weight ratio of 1:80~1:60, wherein the fluorine-containing compound is 1H, 1H, 2H, 2H-perfluorododecanethiol, One or more of heptafluorodecyltriethoxysilane and tridecafluorooctyltriethoxysilane.

[0023] Further, the cleaning additive is composed of 2 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com