Novel air-breathing pulse detonation engine system on basis of two-stage detonation

An engine system and pulse detonation technology, which is applied in the direction of engine components, charging system, turbine/propulsion device air intake, etc., can solve the problem of difficult performance guarantee, long-term stable operation of the engine, and failure to effectively prevent detonation. High-temperature and high-pressure air flow reverse transmission and other problems, to achieve the effect of increasing the single intake air volume, simple system structure, and strong flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

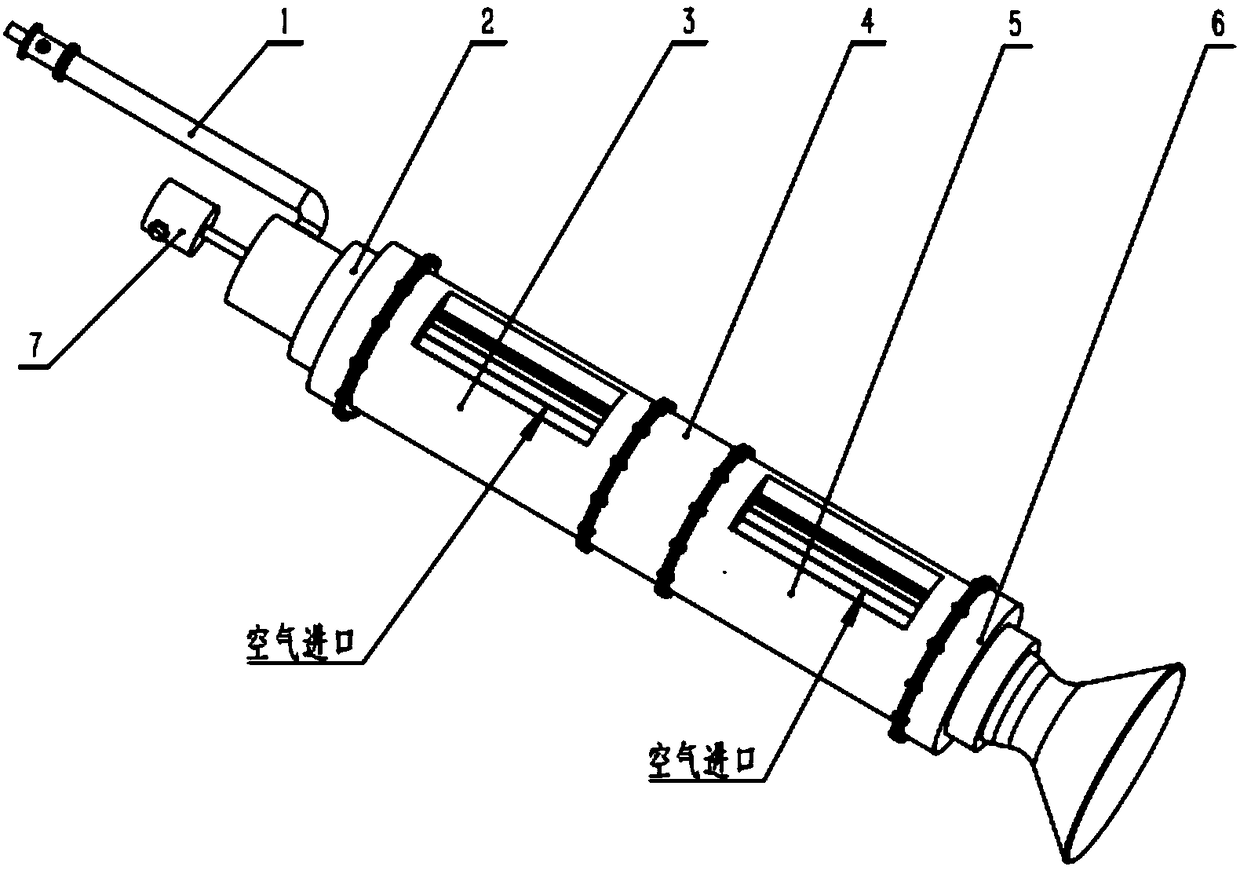

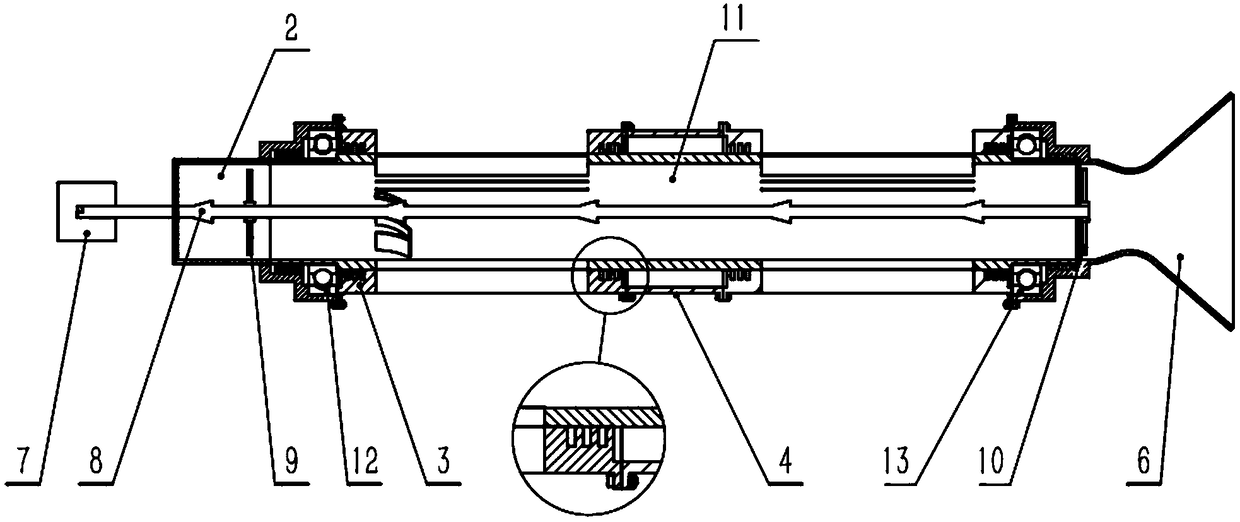

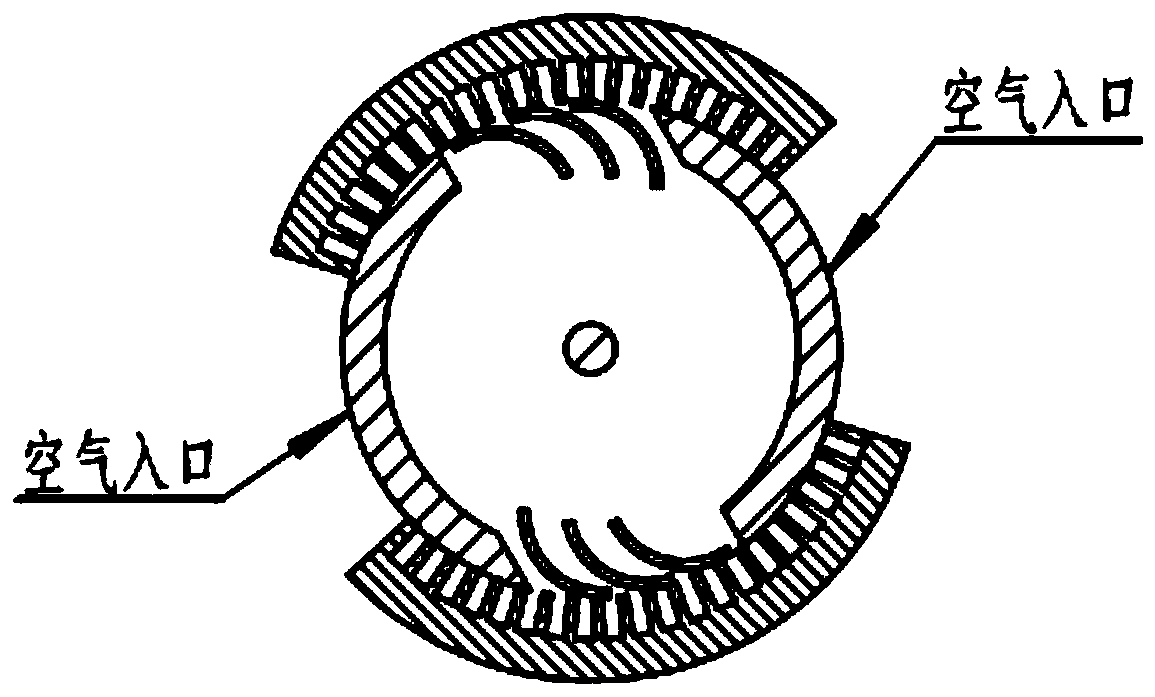

[0027] see figure 1 — Figure 9 , a new air-breathing pulse detonation engine system, including air supply system, detonation system, detonation chamber system, fuel supply system, each component such as figure 1 with figure 2 Assembled as shown, the rest of the system is as Figure 8 Connect as shown. The number and arrangement of the detonation chamber system are determined according to the power required by the aircraft and the structure of the aircraft. The air required for each detonation chamber is provided by an air intake distributor; the air intake distributor connects two air intake systems and sealed pipes- The air inlets of 3 and 5; the main detonation chamber-11 is supported by bearings-12 and 13 installed at both ends of the main detonation chamber, the head of the main detonation chamber-2 is connected with the stationary outer ring of the bearing-12, and detonation Pipe-1 is installed on the head of the main detonation chamber-2, tail nozzle-6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com