Catalyst capable of efficiently decomposing formaldehyde as well as preparation method and application thereof

A catalyst and formaldehyde technology, applied in the field of air purification, can solve the problems of high working temperature, hinder practical application, etc., and achieve the effects of easy operation, easy recovery and immobilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the embodiment of the present invention provides the preparation method of the aforementioned high-efficiency formaldehyde decomposition catalyst, which includes (1) synthesizing a metal complex as an active component; (2) loading the metal complex on a porous carrier. Specifically, the preparation method includes:

[0034] The metal complex and the porous carrier are uniformly mixed in a solvent and reacted at 10-100°C to obtain a catalyst for efficiently decomposing formaldehyde; the metal complex includes [IrCp * Cl 2 ] 2 , [RhCp * Cl 2 ] 2 , [Ir(COD)Cl 2 ] 2 and [Rh(COD)Cl 2 ] 2 Any one or a combination of two or more of them, where Cp * is pentamethylcyclopentadienyl, and COD is 1,5-cyclooctadienyl.

[0035] In some embodiments, the preparation method of the metal complex comprises:

[0036] Appropriate amount of Cp *H (pentamethylcyclopentadiene) and / or 1,5-cyclooctadiene was added to H 2 IrCl 6 and / or RhCl 3 solution, reflux for 3...

Embodiment 1

[0063] 1. the method for preparing described catalyst in the present embodiment is:

[0064] Add the carrier polypyrrole to ethanol, heat and stir, and then add [IrCp * Cl 2 ] 2 , and then stirred at 20-100° C. overnight. After the reaction, the resulting precipitate was filtered, washed, and dried in sequence to obtain an iridium complex catalyst.

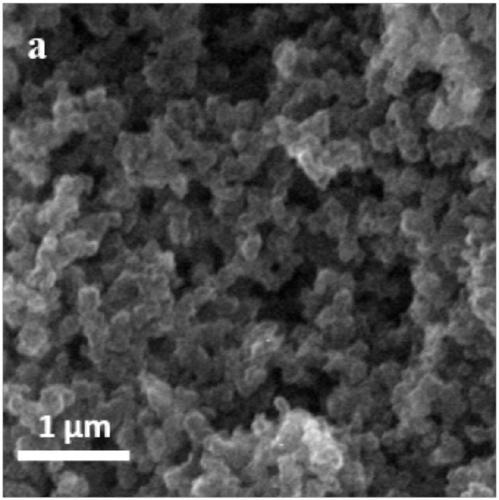

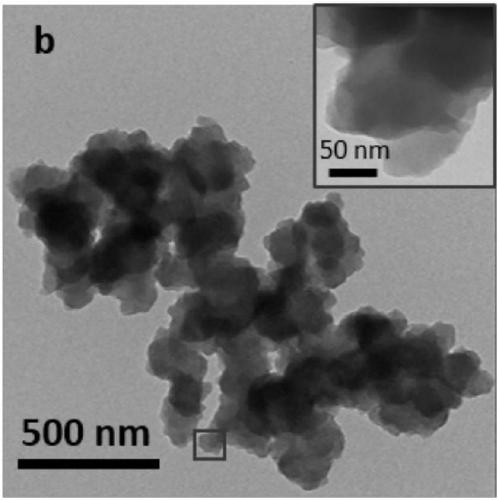

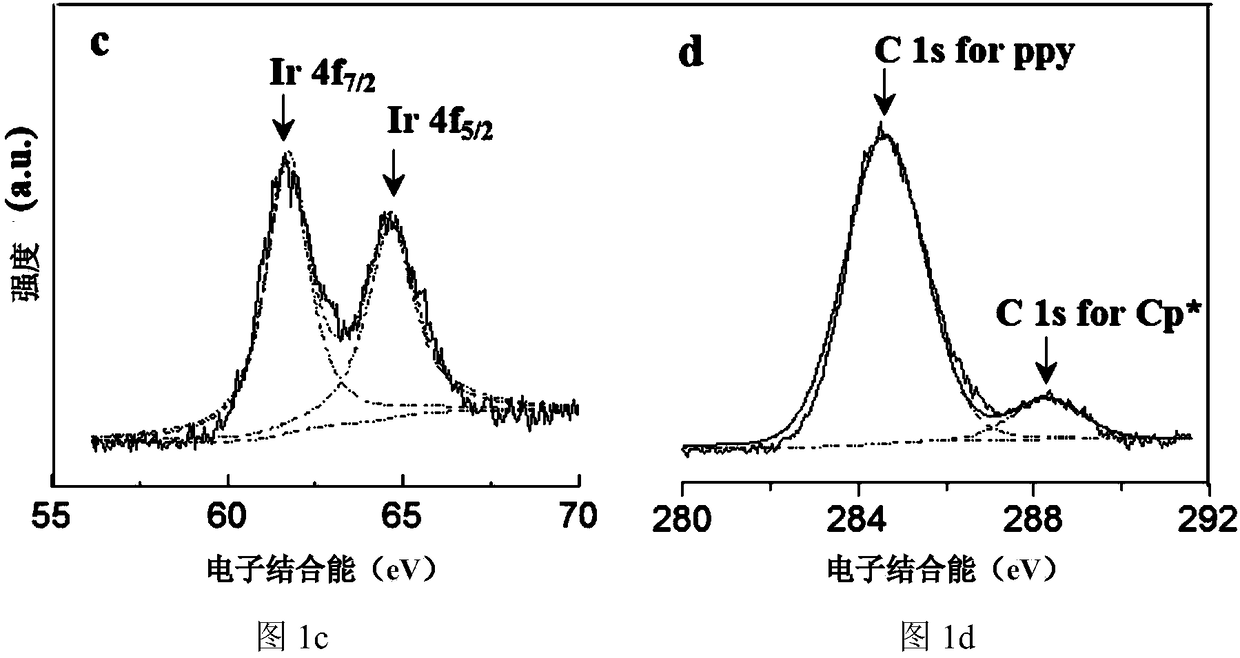

[0065] 2. The characterization of the iridium complex catalyst obtained in the present embodiment

[0066] Adopt transmission electron microscope (TEM), scanning electron microscope (SEM) and X-ray photoelectron spectrum (XPS) to characterize the morphology of the iridium complex catalyst obtained in this embodiment, the results refer to Figure 1a to Figure 1d shown. Depend on Figure 1a and Figure 1b It can be seen that the surface of the catalyst provided by this example is distributed with a lot of clustered substances, the shape is similar to that of coral, and the specific surface area is large, which provides a suffic...

Embodiment 2

[0081] The preparation method of the catalyst in this embodiment 2 is basically the same as that of embodiment 1, the difference is that the raw materials used are different, for example, the metal complex can be [RhCp * Cl 2 ] 2 , the porous carrier is polypyrrole.

[0082].The method for preparing described catalyst in the present embodiment is:

[0083] Put the carrier polypyrrole into a solvent, the solvent is one or more combinations of methanol, ethanol, propanol, isopropanol, butanol and water, heat and stir, and then add [RhCp * Cl 2 ] 2 , and then stirred at 20-100° C. overnight. After the reaction, the obtained precipitate was filtered, washed and dried in sequence to obtain a rhodium complex catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com