Liquid magnesium chloride granulation and particle classification collection equipment and method

A particle classification and collection equipment technology, applied in the direction of granulating raw materials, chemical instruments and methods, lighting and heating equipment, etc., can solve the difficulty of waste heat recovery, small thermal conductivity, latent heat and sensible heat have not been recycled and other issues to achieve the effect of increasing the added value of products and realizing hierarchical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

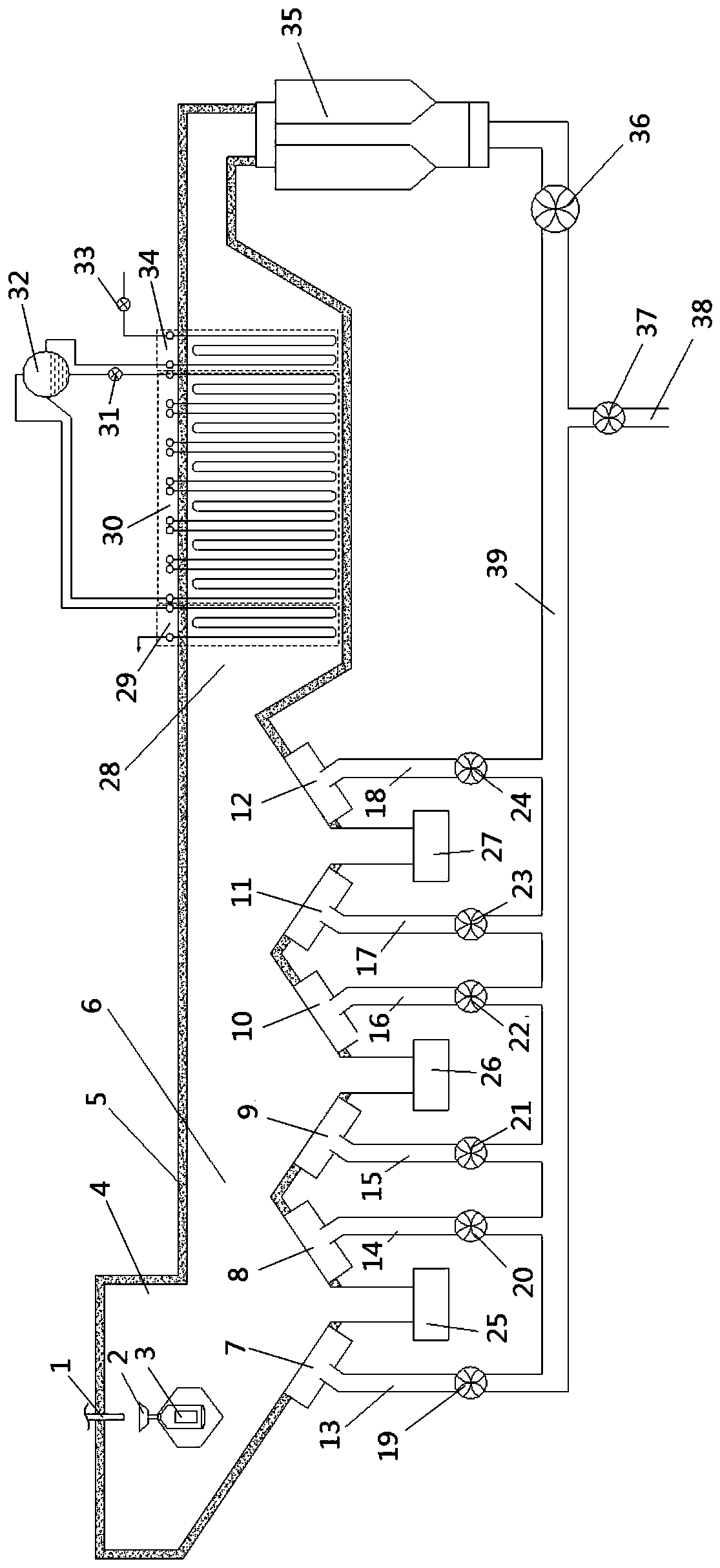

[0022] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The directional nouns such as "up" and "down" mentioned in this article are based on figure 1 For reference.

[0023] refer to figure 1 , a liquid magnesium chloride granulation and particle classification collection equipment is provided in this embodiment, the granulation and particle classification collection equipment includes a granulation channel 4, a granulator 2, a driver 3, a classification collection channel 6 and at least two fluidized unit.

[0024]Wherein, the granulation channel 4 is connected with the feed port 1, and the liquid magnesium chloride enters the granulation channel 4 from the feed port 1. The granulator 2 and the driver 3 are arranged in the granulation channel 4 , the top surface of the granulator 2 is a plane or has a concave cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com