Staged porous charcoal, and preparing method and applications thereof

A hierarchical porous, raw material technology, which is applied in the preparation/purification of carbon, general water supply saving, testing water, etc., can solve the problems of cumbersome preparation method steps, unfriendly environment, high cost, short cycle, omit preparation steps, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Synthetic raw materials:

[0049] Raw material A is potassium citrate;

[0050] Raw material B is calcium citrate;

[0051] Weigh raw material A and raw material B with a mass ratio of 5:2 and mix them evenly, place them in a tubular muffle furnace, and raise the temperature to 850°C under nitrogen protection (gas flow rate: 100mL / min), with a heating rate of 5°C / min , the holding time is 1h, after the reaction is completed, the temperature is lowered to room temperature, and the sample is taken out. Utilize 10% hydrochloric acid solution to pickle the sample, then dry it in an oven at 120°C, and pulverize it to obtain a graded porous carbon material (MPC 5 / 2 ).

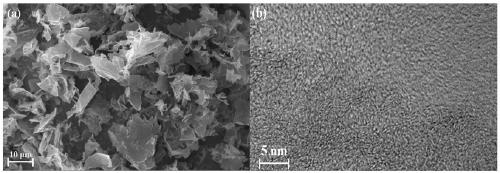

[0052] Such as figure 1 a and figure 1 As shown in b, the prepared MPC 5 / 2 It is a flaky structure with partial graphitization, and an obvious and widely distributed pore structure can be seen.

Embodiment 2

[0054] Synthetic raw materials:

[0055] Raw material A is potassium citrate;

[0056] Raw material B is calcium citrate;

[0057] Weigh raw materials A and raw materials B with a mass ratio of 5:0.5 and mix them evenly, place them in a tubular muffle furnace, and raise the temperature to 850°C under nitrogen protection (gas flow rate 100mL / min), with a heating rate of 5°C / min , the holding time is 1h, after the reaction is completed, the temperature is lowered to room temperature, and the sample is taken out. Utilize 10% hydrochloric acid solution to pickle the sample, then dry it in an oven at 120°C, and pulverize it to obtain a graded porous carbon material (MPC 5 / 0.5 ).

Embodiment 3

[0059] Synthetic raw materials:

[0060] Raw material A is potassium citrate;

[0061] Raw material B is calcium citrate;

[0062] Weigh raw materials A and raw materials B with a mass ratio of 5:1 and mix them evenly, place them in a tubular muffle furnace, and raise the temperature to 850°C under nitrogen protection (gas flow rate 100mL / min), with a heating rate of 5°C / min , the holding time is 1h, after the reaction is completed, the temperature is lowered to room temperature, and the sample is taken out. Utilize 10% hydrochloric acid solution to pickle the sample, then dry it in an oven at 120°C, and pulverize it to obtain a graded porous carbon material (MPC 5 / 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com