Preparation method of amphiphilic affinity polymer microspheres with core-shell structure

A core-shell structure and polymer technology, applied in the field of amphiphilic affinity microsphere technology and protein protection research, can solve the problems of difficult dispersion, difficult denaturation mechanism, weakened ability of protection and refolding, etc., and achieve the effect of overcoming the difficulty of removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Preparation of an amphiphilic polymer with a core-shell structure

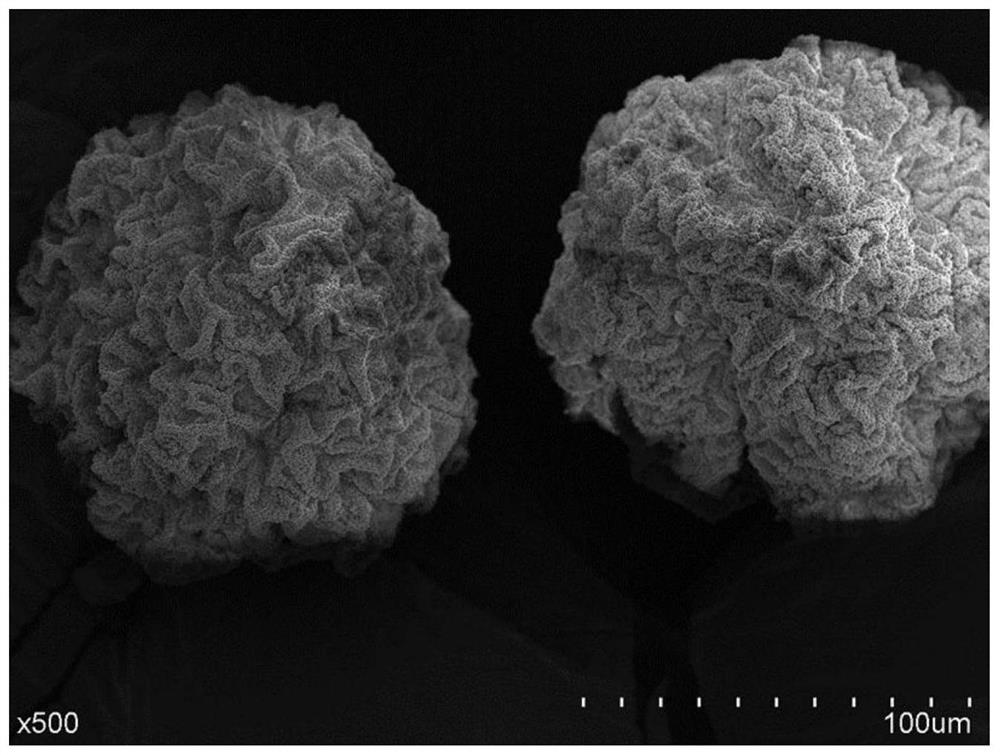

[0038] (1) Preparation of hydrophobic particles poly(divinylbenzene-co-4-vinylphenylboronic acid) microspheres, 10mmol of 4-vinylbenzeneboronic acid, 10mmol of divinylbenzene, dissolved in 160mL of acetonitrile, added 10mg of initiator ammonium persulfate, sealed after passing nitrogen gas. Oil bath at 70°C, polymerize for 30 minutes, after the solution becomes turbid, connect to distillation equipment, increase the temperature of oil bath to 110°C, continue the reaction until half of the volume of acetonitrile is evaporated, and the time is controlled within 2 hours. After the polymerization reaction, use a G5 sand core funnel to carry out suction filtration, then wash with acetone, tetrahydrofuran, and methanol in sequence, and vacuum-dry it for later use.

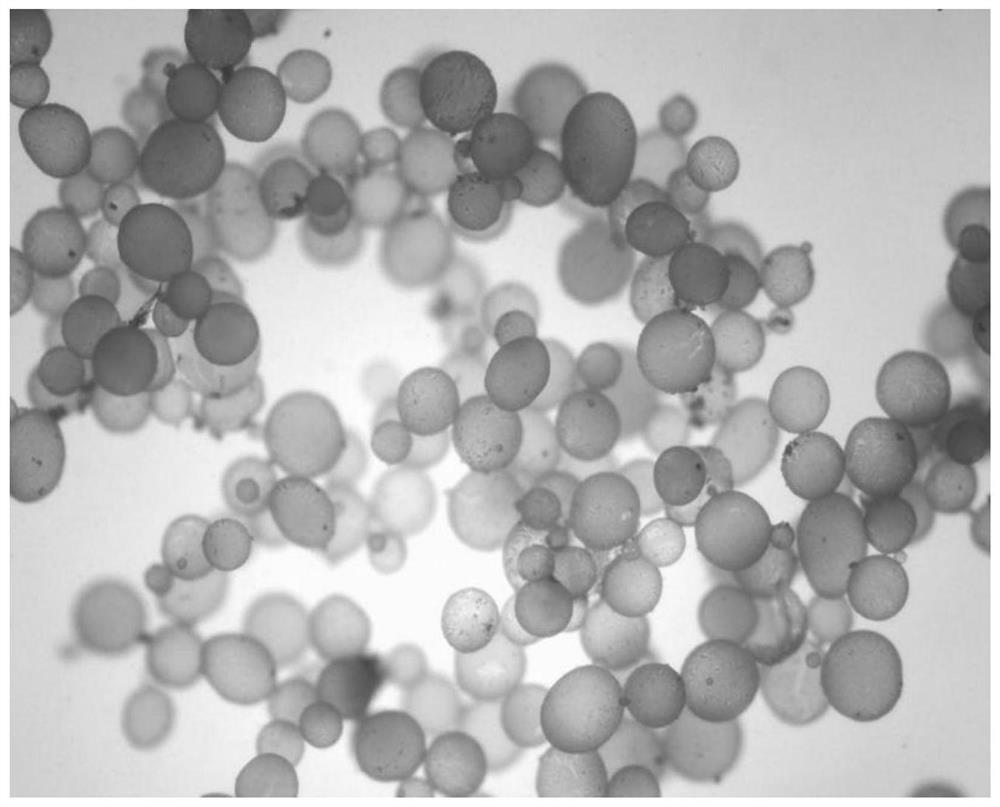

[0039] (2) Preparation of Amphoteric Core-Shell Polymer Microspheres by Pickering Emulsion Polymerization

[0040] Add 120 mg of t...

Embodiment 2

[0042] Thermostability test of horseradish peroxidase maintained by amphiphilic polymer microspheres with core-shell structure

[0043] Take 5mg of amphoteric core-shell polymer microspheres and add to 2mL to a concentration of 0.5mg mL -1 horseradish peroxidase in aqueous solution. This aqueous horseradish peroxidase solution was heated at 70° C. for 1 hour. After the supernatant was removed by centrifugation, 100 μL of DAB horseradish peroxidase chromogenic reagent was added. The material was observed under an ordinary optical microscope, and it was found that the interior of the microspheres changed from colorless to red, which indicated that the amphiphilic polymer microspheres with the core-shell structure could immobilize the horseradish peroxidase in the interior under high temperature conditions. Hydrophilic core while maintaining the activity of horseradish peroxidase.

[0044] The control group was the above solution without adding amphoteric core-shell polymer mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com