A kind of preparation method of polyaluminum calcium silicate-sodium alginate composite flocculant

A composite flocculant and sodium alginate technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve complex preparation process, general flocculation effect, and chemical residues and other problems, to achieve the effect of simple operation, good flocculation effect, and enhanced electric neutralization mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

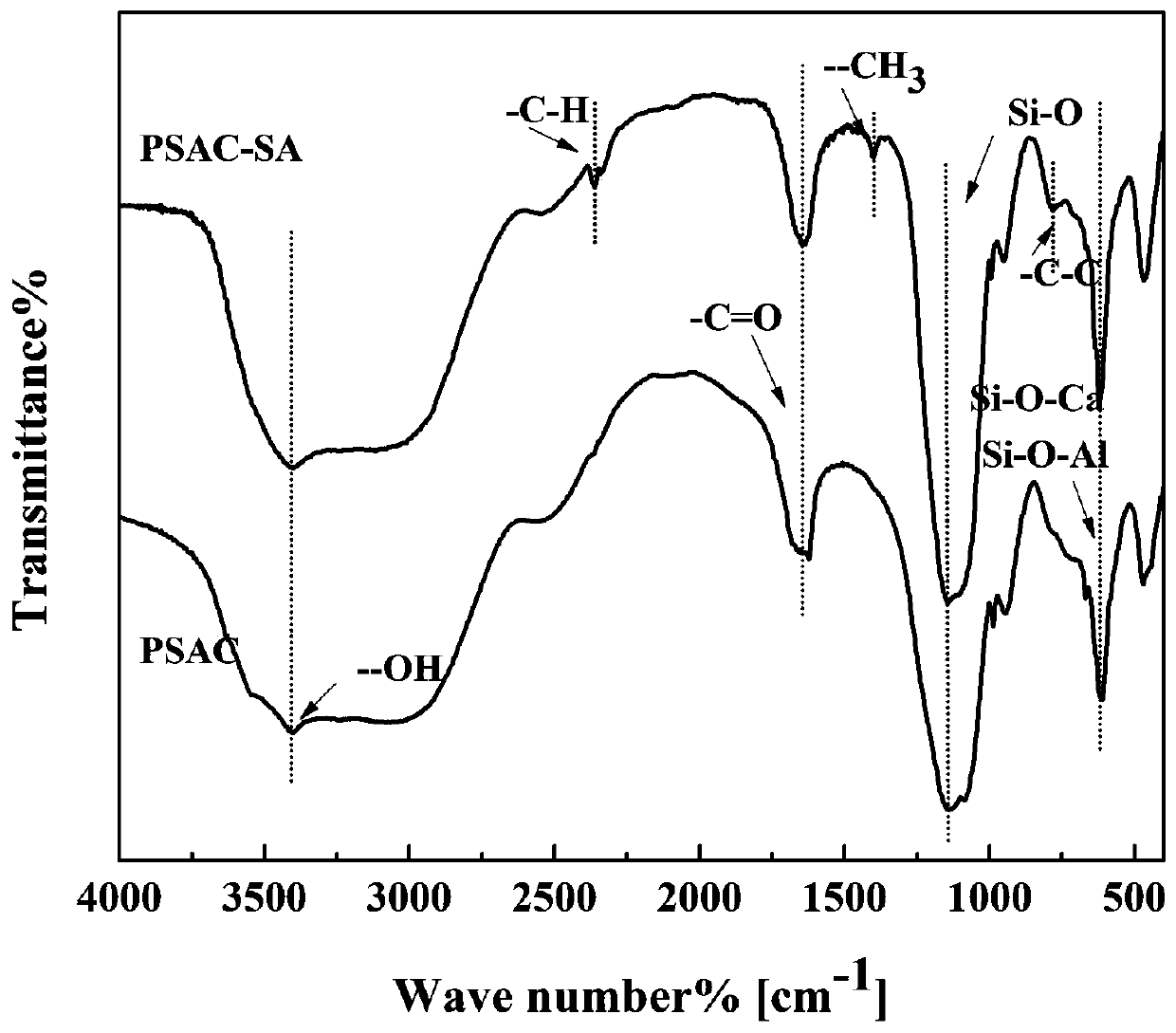

Image

Examples

Embodiment 1

[0043] Prepare 0.15mol / L sodium silicate solution and slowly add 20% H 2 SO 4 Adjust the pH to 3, stir in a water bath for 2 hours, let stand and mature for 24 hours to prepare polysilicic acid, add 6.6ml of 0.4mol / L aluminum salt, 1.7ml of 0.8mol / L calcium salt, stir in a water bath at 40°C for 2 hours, let stand and mature for 24 hours, Preparation of calcium aluminum silicate flocculant.

[0044] Use 1% acetic acid to pre-treat sodium alginate, prepare 7.5% sodium alginate solution, stir in a water bath at 60°C for 1.5 hours, take 8ml and add it to polyaluminum calcium silicate flocculant, stir and heat, let stand and mature for 24 hours to obtain Polyaluminum calcium silicate-sodium alginate composite flocculant.

[0045] Take an appropriate amount of polyaluminum calcium silicate-sodium alginate composite flocculant and add it to the simulated water sample. The flocculation efficiency is significantly improved, and the flocs are compact, and the effect is remarkable. Th...

Embodiment 2

[0047] Prepare 0.20mol / L sodium silicate solution and slowly add 20% H 2 SO 4 Adjust the pH to 4, stir in a water bath for 2 hours, let stand and mature for 12 hours to prepare polysilicic acid, add 7.4ml of 0.4mol / L aluminum salt, 0.8ml of 0.8mol / L calcium salt, stir in a water bath at 50°C for 2 hours, let stand and mature for 12 hours, Preparation of calcium aluminum silicate flocculant.

[0048] Pre-treat sodium alginate with 1% acetic acid, prepare a 6% sodium alginate solution, stir in a water bath at 50°C for 2 hours, take 6ml and add it to the polyaluminum calcium silicate flocculant, stir and heat, stand and mature for 12 hours to obtain Polyaluminum calcium silicate-sodium alginate composite flocculant.

[0049] Take an appropriate amount of polyaluminum calcium silicate-sodium alginate composite flocculant and add it to the simulated water sample. The flocculation efficiency is significantly improved, and the flocs are compact, and the effect is remarkable. The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com