A kind of method that reclaims dimethyl sulfate from vacuum

A technology of dimethyl sulfate and vacuum air, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve material waste, increase difficulty of alcohol sewage treatment, reduce recovery rate of dimethyl sulfate refining, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

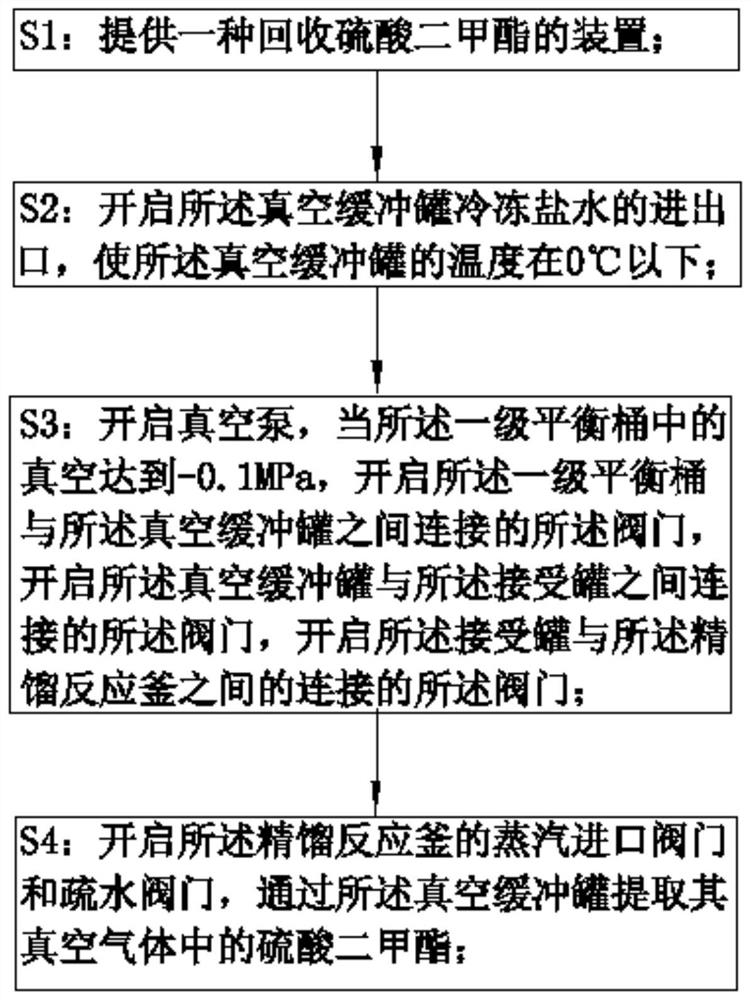

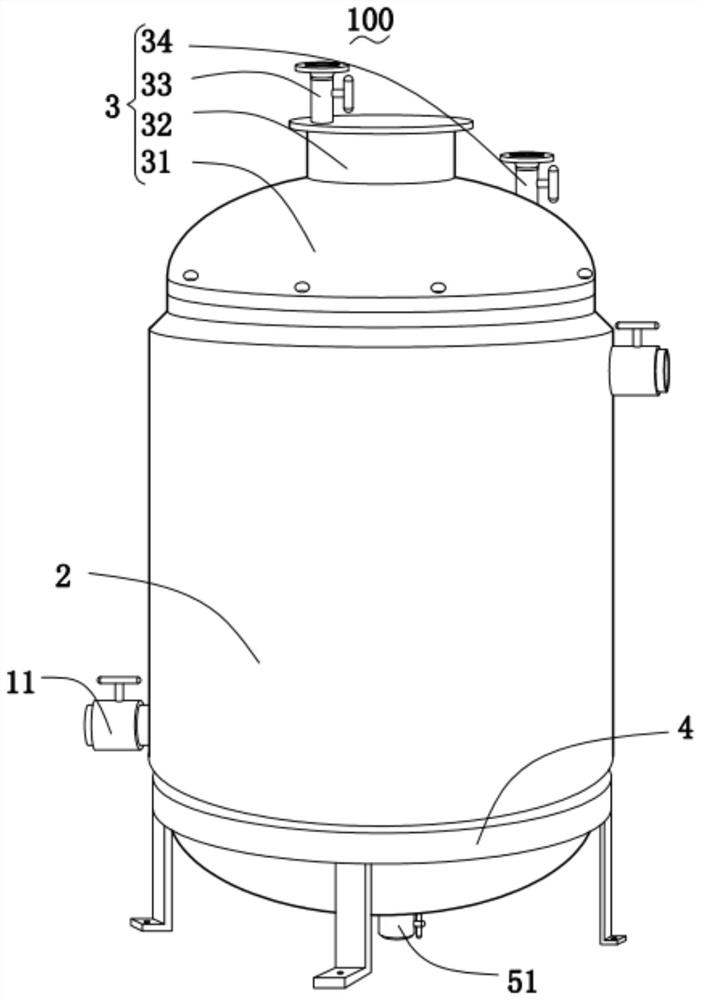

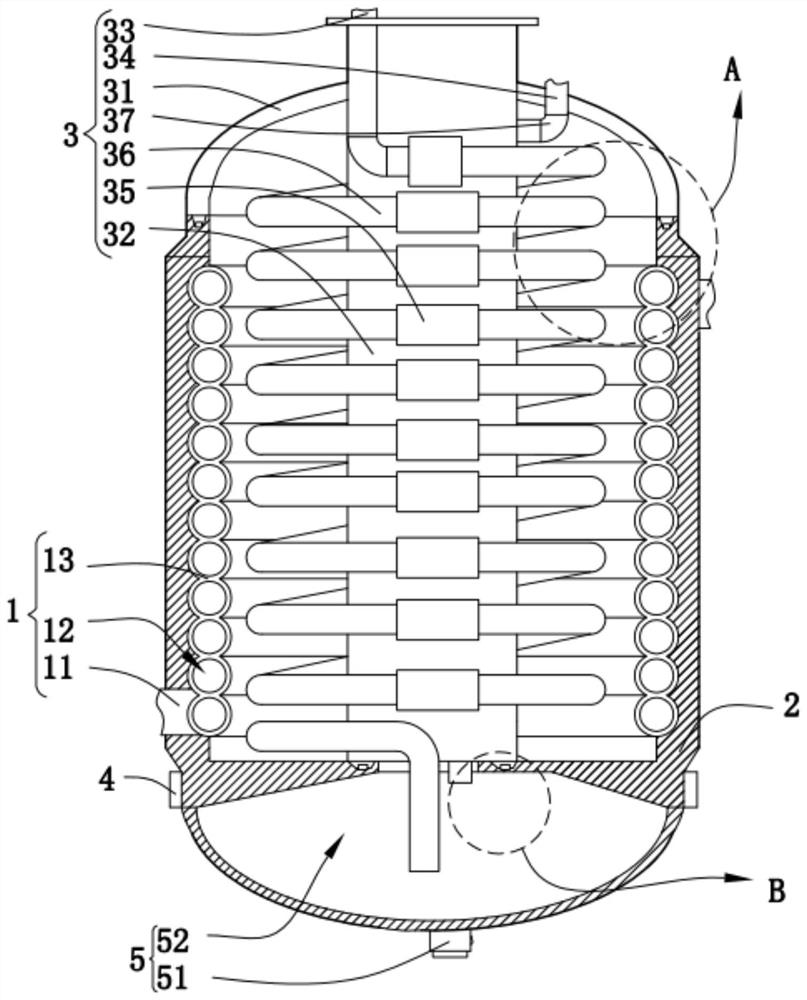

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 ,in, figure 1 A flow chart of a preferred embodiment of the method for reclaiming dimethyl sulfate from vacuum provided by the invention; figure 2 for figure 1 The overall structure schematic diagram of a kind of device that reclaims dimethyl sulfate provided as shown; image 3 for figure 2 The schematic diagram of the connection structure between the buffer structure and the storage tank shown; Figure 4 for image 3 The enlarged schematic diagram of part A shown; Figure 5 for image 3 The enlarged schematic diagram of part B shown; Image 6 for figure 2 A flow chart of a device for reclaiming dimethyl sulfate shown. The method for reclaiming dimethyl sulfate from vacuum comprises the following steps:

[0030]Step 1: provide a kind of device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com