Green preparation method of high-purity tea saponin

A tea saponin, green technology, applied in the field of green preparation of high-purity tea saponin, can solve the problems of low extraction rate and poor purity of the product, and achieve the effects of high product purity, greenness, and less dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

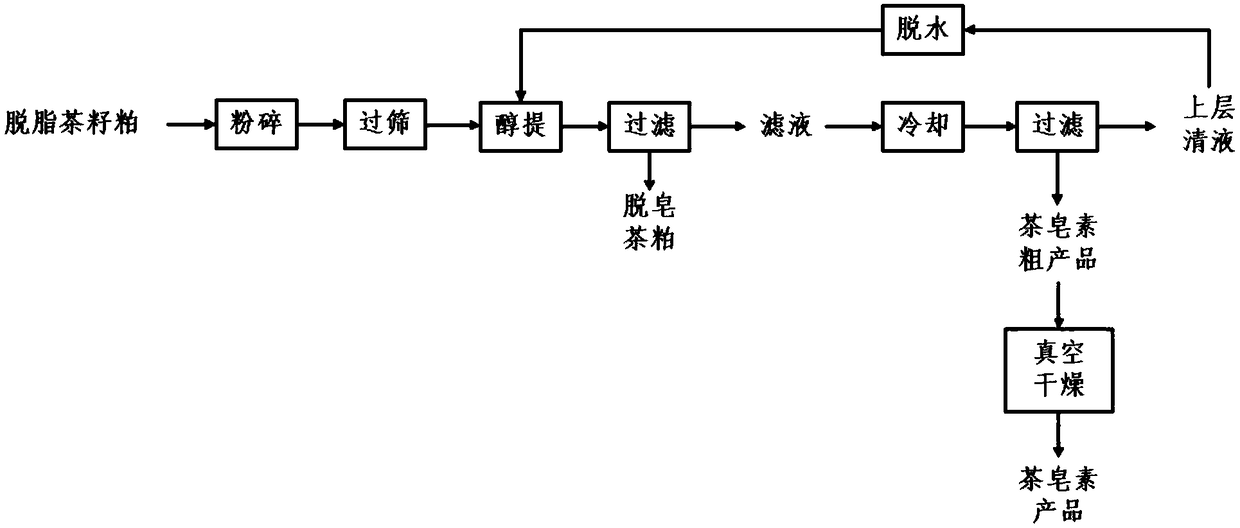

[0023] Embodiment 1. below in conjunction with attached figure 1 The green preparation method of high-purity tea saponin described in the present invention is described. The organic solvent described in this implementation is a mixture of two different polar solvents: absolute ethanol and camellia seed oil.

[0024] (1) Raw material pretreatment: take the defatted camellia oleifera seed meal, wherein the residual oil content is 2% of the mass of the camellia oleifera seed meal, grind and sieve after drying, take the camellia oleifera seed meal powder of 50 mesh below 60 mesh, and set aside.

[0025] (2) Take 10 g of Camellia oleifera seed meal powder obtained in step (1), add 95 mL of absolute ethanol and 5 mL of camellia seed oil, and stir evenly.

[0026] (3) Adjust the temperature of the feed solution in step (2) to 80° C., heat preservation and pretreatment for 4 hours, and carry out alcohol extraction.

[0027] (4) Filtrate the feed liquid obtained in step (3) while it i...

Embodiment 2

[0029] Embodiment 2. The green preparation method of high-purity tea saponin.

[0030] Repeat embodiment 1, the difference between this embodiment and embodiment 1 is that the lower layer precipitation described in step (4) in the present embodiment first passes through cold ethanol (cold ethanol refers to the ethanol identical with cooling temperature, refers to 4 here. ℃ of absolute ethanol, the same below), and then the precipitate is vacuum-dried to obtain a white tea saponin product. In this embodiment, by increasing the processing steps of cold ethanol cleaning, the yield of the final product is 82%, and the purity is 96%. .

Embodiment 3

[0031] Embodiment 3. repeat embodiment 1, the difference with embodiment 1 is, the degreased camellia oleifera seed dregs described in step (1) in the present embodiment, wherein residual grease amount is 10% of the camellia oleifera seed dregs quality.

[0032] This example examines that when the camellia oleifera seed meal contains relatively high oil residue, gray-white tea saponin with high yield and purity can still be obtained through the extraction method. The yield of the final product is 85%, and the purity is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com