Oil extraction method for vegetable oil microcapsule powder

An extraction method and oil extraction technology, which are applied in the production of fat/fat and fat production, can solve the problems of complex process, large consumption of reagents, long time, etc., and achieve mild extraction conditions, good application prospects, and reduced usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

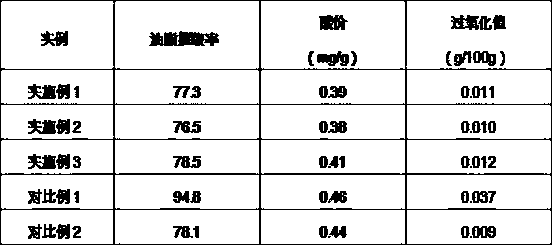

Examples

Embodiment 1

[0019] a) Weigh 15 g of linseed oil powder (Dalian Yinuo Biological Co., Ltd., oil content 52%) into a centrifuge cup, add 15 mL of water and stir with a glass rod to dissolve and form an emulsion, then add 30 mL of absolute ethanol and stir Mix evenly, then add 60 mL of petroleum ether at 30-60°C, mix well, cover the mouth of the cup with plastic wrap, and seal it with a rubber band;

[0020] b) Sonicate at 1000W, 80KHz for 15 minutes, centrifuge the ultrasonically processed sample at 3000 rpm for 10 minutes, use a separatory funnel to separate layers, discard the lower layer solution, and pass the upper layer liquid through a bath filled with a little anhydrous sodium sulfate. After filtering through the funnel, transfer it to an evaporating flask, absorb 25mL of petroleum ether at 30-60°C to wash the funnel to absorb grease, pour the eluent into the evaporating flask, and evaporate the solvent to dryness with a rotary evaporator in a water bath below 40°C, that is 6.1g of o...

Embodiment 2

[0022] a) Weigh 15 g of the same batch of linseed oil powder as in Example 1 into a centrifuge cup, add 25 mL of water and stir with a glass rod to dissolve and form an emulsion, then add 45 mL of ethanol with a volume fraction of 95% and stir evenly, and then Add 90 mL of petroleum ether at 30-60°C, mix well, cover the mouth of the cup with plastic wrap, and seal it with a rubber band;

[0023] b) Sonicate for 10 min at 1000W, 80KHz, centrifuge the ultrasonically processed sample at 3000 rpm for 5min, separate layers with a separatory funnel, discard the lower layer solution, and pass the upper layer liquid through a funnel filled with a little anhydrous sodium sulfate After filtering, transfer it to an evaporating flask, draw 25mL of petroleum ether at 30-60°C to absorb the oil in the rinsing funnel, put the eluent into the evaporating flask, and evaporate the solvent to dryness with a rotary evaporator in a water bath below 40°C to obtain Oil 6.0g, oil extraction rate 76.5%...

Embodiment 3

[0025] a) Weigh 20 g of the same batch of linseed oil powder as in Example 1 into a centrifuge cup, add 30 mL of water and stir with a glass rod to dissolve and form an emulsion, then add 60 mL of ethanol with a volume fraction of 90% and stir evenly. Then add 90mL of petroleum ether at 30-60°C, mix well, cover the mouth of the cup with plastic wrap, and seal it with a rubber band;

[0026] b) Sonicate at 1000W, 37KHz for 10min, centrifuge the sonicated sample at 3000 rpm for 5min, separate layers with a separatory funnel, discard the lower layer solution, and filter the upper layer liquid through a funnel filled with a little anhydrous sodium sulfate Then transfer to the evaporating flask, draw 25mL of petroleum ether at 30-60°C to absorb the oil in the rinsing funnel, pour the eluent into the evaporating flask, evaporate the solvent to dryness with a rotary evaporator in a water bath below 40°C, and obtain the oil 8.2g, the oil extraction rate is 78.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com