Method for achieving classified recovery of metals in circuit boards

A technology for circuit boards and metals, which is applied in the field of classified recycling of metals in circuit boards, to achieve the effects of improving efficiency and product purity, improving separation effects, and avoiding operational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

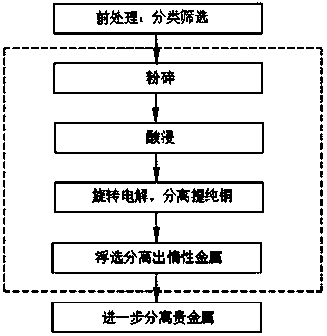

[0048] A method for sorting and recycling metals in circuit boards, comprising the following steps:

[0049] S1. Use a pulverizer to pulverize the circuit board and pass it through a 25-mesh screen;

[0050] S2. Add 20L 1mol / L dilute hydrochloric acid to the pulverized particles to react the active metal with the acid to elute, filter and separate to obtain the filtrate and filter residue, and reclaim the salt solution containing the active metal from the filtrate;

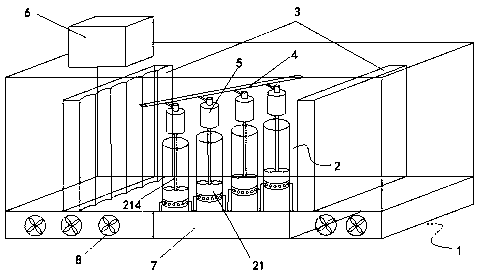

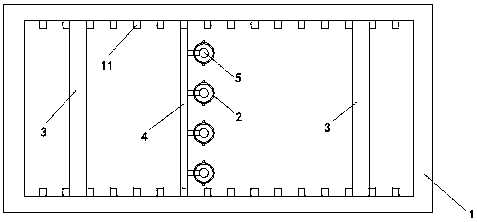

[0051] S3. Add the filter residue to the above-mentioned anode rotary mortar electrolysis device, electrolytically dissolve the copper particles on the substrate in the electrolyte, and make the precious metal deposited on the copper surface detach from the substrate, and at the same time recover the refined copper at the cathode;

[0052] S4. Transfer the precious metal and resin in the anode tank to CCl 4 In the flotation agent, the difference in density is used to precipitate the precious metal, the resin floa...

Embodiment 2

[0076] A method for sorting and recycling metals in circuit boards, comprising the following steps:

[0077] S1. Use a pulverizer to pulverize the circuit board and pass through a 100-mesh screen;

[0078] S2. Add 10L 3mol / L dilute sulfuric acid to the pulverized particles to dissolve the active metal and the acid, filter and separate to obtain the filtrate and filter residue, and reclaim the salt solution containing the active metal from the filtrate;

[0079] S3. Add the filter residue to the above-mentioned anode rotary mortar electrolysis device, electrolytically dissolve the copper particles on the substrate in the electrolyte, and make the precious metal deposited on the copper surface detach from the substrate, and at the same time recover the refined copper at the cathode;

[0080] S4. Transfer the precious metal and resin in the anode tank to CCl 4 In the flotation agent, the difference in density is used to precipitate the precious metal, the resin floats on the sol...

Embodiment 3

[0088] A method for sorting and recycling metals in circuit boards, comprising the following steps:

[0089] S1. Use a pulverizer to crush the circuit board and pass it through a 65-mesh screen;

[0090] S2. Add 18L 1.5mol / L dilute hydrochloric acid to the pulverized particles to react the active metal with the acid to elute, filter and separate to obtain the filtrate and filter residue, and reclaim the salt solution containing the active metal from the filtrate;

[0091] S3. Add the filter residue to the above-mentioned anode rotary mortar electrolysis device, electrolytically dissolve the copper particles on the substrate in the electrolyte, and make the precious metal deposited on the copper surface detach from the substrate, and at the same time recover the refined copper at the cathode;

[0092] S4. Transfer the precious metal and resin in the anode tank to CCl 4 In the flotation agent, the difference in density is used to precipitate the precious metal, the resin floats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com