Compound water-retaining agent for Chinese-style meat dishes, preparation method thereof and application thereof

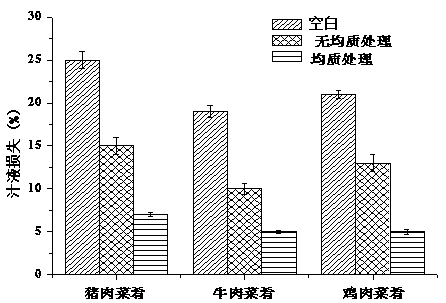

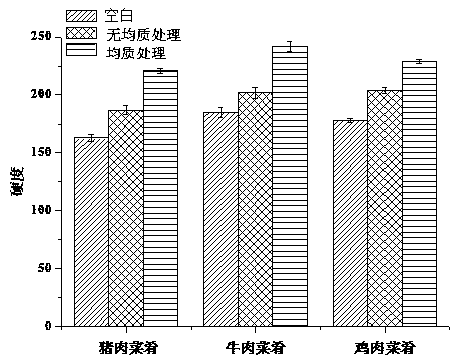

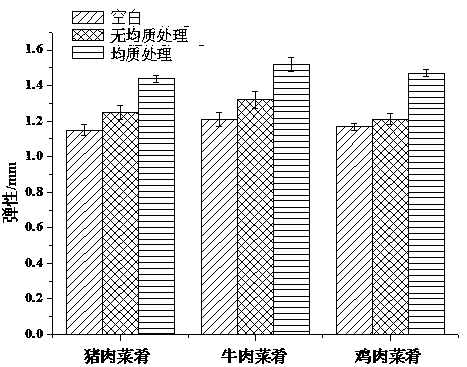

The technology of a water-retaining agent and meat is applied in the field of compound water-retaining agent for Chinese-style meat dishes and its preparation to achieve the effects of improving whiteness, improving structural quality and improving water-holding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Carrageenan oligosaccharide nano-liposome: mix soybean lecithin and cholesterol according to the mass ratio of 1:3, and dissolve it in the external aqueous phase ether solvent, and take a carrageenan oligosaccharide solution with a concentration of 10 mg / mL As the inner water phase, mix according to the volume ratio of the outer and inner water phases of 4:1.25, homogenize once in a dynamic high-pressure micro-fluidizer at 80MPa and 45°C for 5 minutes to form a stable emulsion, and transfer the emulsion into an evaporating bottle 35°C rotary evaporation until ether evaporates to dryness, then add 300~500mL PBS buffer solution and Tween 80 with 1% solution volume, continue rotary evaporation to evaporate all organic solvents, and then ultrasonic treatment for 20 min to obtain carrageenan oligoglycolipid plastid.

[0029] 2. Secondary homogenization: add 0.2% carrageenan oligosaccharide nanoliposome, 0.2% soybean protein isolate, 0.1% trisodium citrate, 0.4% sodium cas...

Embodiment 2

[0033] 1. Carrageenan oligosaccharide nano-liposome: mix soybean lecithin and cholesterol according to the mass ratio of 1:3, and dissolve it in the external aqueous phase ether solvent, and take a carrageenan oligosaccharide solution with a concentration of 10 mg / mL As the inner water phase, mix according to the volume ratio of the outer and inner water phases of 4:1.25, homogenize once in a dynamic high-pressure micro-fluidizer at 80MPa and 45°C for 5 minutes to form a stable emulsion, and transfer the emulsion into an evaporating bottle 35°C rotary evaporation until ether evaporates to dryness, then add 300~500mL PBS buffer solution and Tween 80 with 1% solution volume, continue rotary evaporation to evaporate all organic solvents, and then ultrasonic treatment for 20 min to obtain carrageenan oligoglycolipid plastid.

[0034] 2. Secondary homogenization: Add 0.4% carrageenan oligosaccharide nanoliposomes, 0.3% soybean protein isolate, 0.2% trisodium citrate, 0.6% sodium ca...

Embodiment 3

[0038] 1. Carrageenan oligosaccharide nano-liposome: mix soybean lecithin and cholesterol according to the mass ratio of 1:3, and dissolve it in the external aqueous phase ether solvent, and take a carrageenan oligosaccharide solution with a concentration of 10 mg / mL As the inner water phase, mix according to the volume ratio of the outer and inner water phases of 4:1.25, homogenize once in a dynamic high-pressure micro-fluidizer at 80MPa and 45°C for 5 minutes to form a stable emulsion, and transfer the emulsion into an evaporating bottle 35°C rotary evaporation until ether evaporates to dryness, then add 300~500mL PBS buffer solution and Tween 80 with 1% solution volume, continue rotary evaporation to evaporate all organic solvents, and then ultrasonic treatment for 20 min to obtain carrageenan oligoglycolipid plastid.

[0039] 2. Secondary homogenization: add 0.5% carrageenan oligosaccharide nanoliposomes, 0.3% soybean protein isolate, 0.2% trisodium citrate, 0.5% sodium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com