Fixing device for ligament reconstruction and use method thereof

A technology for ligament reconstruction and fixation devices, which is applied in the direction of ligaments and muscles, which can solve the problems of increased contact area between the fixation device and the outer bone of the bone canal, small bone plate falling, etc., so as to improve the satisfaction of surgery and reduce the chance of revision , fixed effect, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Magnesium ingots with a purity greater than 99.9%, Mg-Ca master alloys with a purity greater than 99.9%, and zinc particles with a purity greater than 99.9% are mixed according to a certain ratio and treated as raw materials in a vacuum melting furnace. After vacuum melting, 0.92wt %Ca, 2.17wt%Zn, magnesium alloy with impurity content less than 0.01%. The obtained magnesium alloy is extruded into a Φ12mm bar after removing surface defects, and then swaged to obtain a Φ5mm bar. The measured mechanical properties of the magnesium-zinc-calcium bar obtained in this embodiment are: yield strength ≥ 250 MPa, tensile strength ≥ 320 MPa, and elongation ≥ 10%. Its grain diameter is ≤8μm.

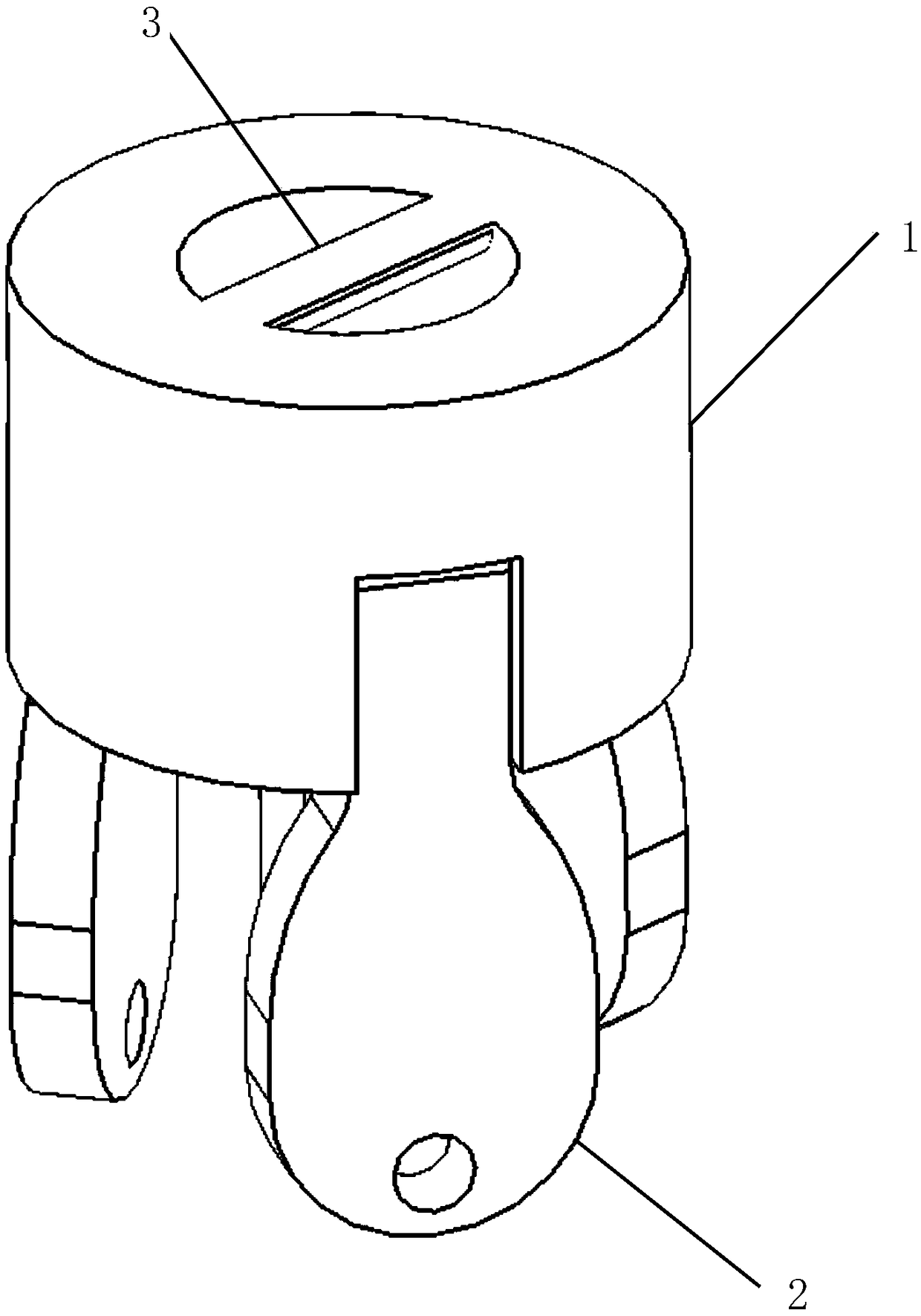

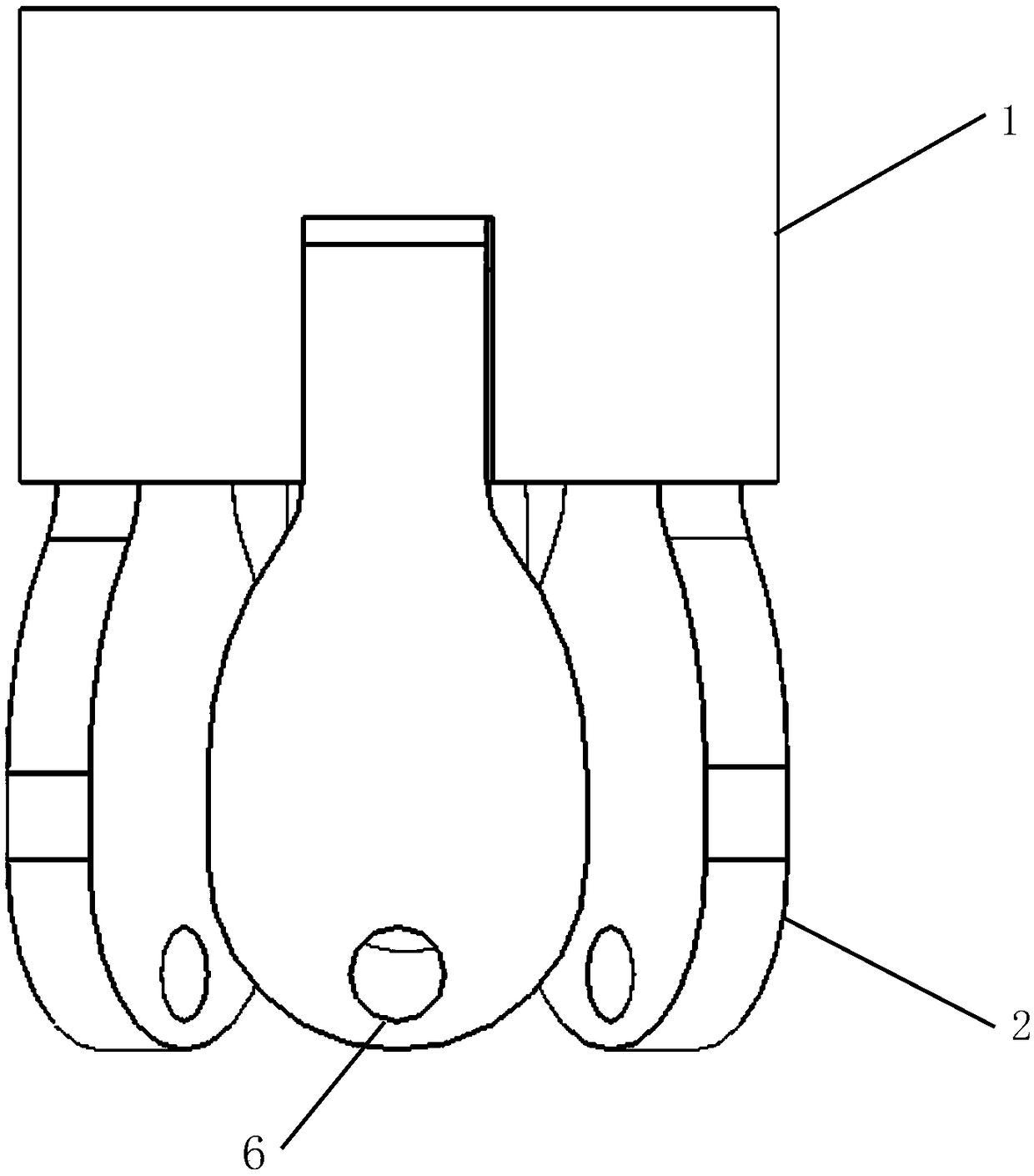

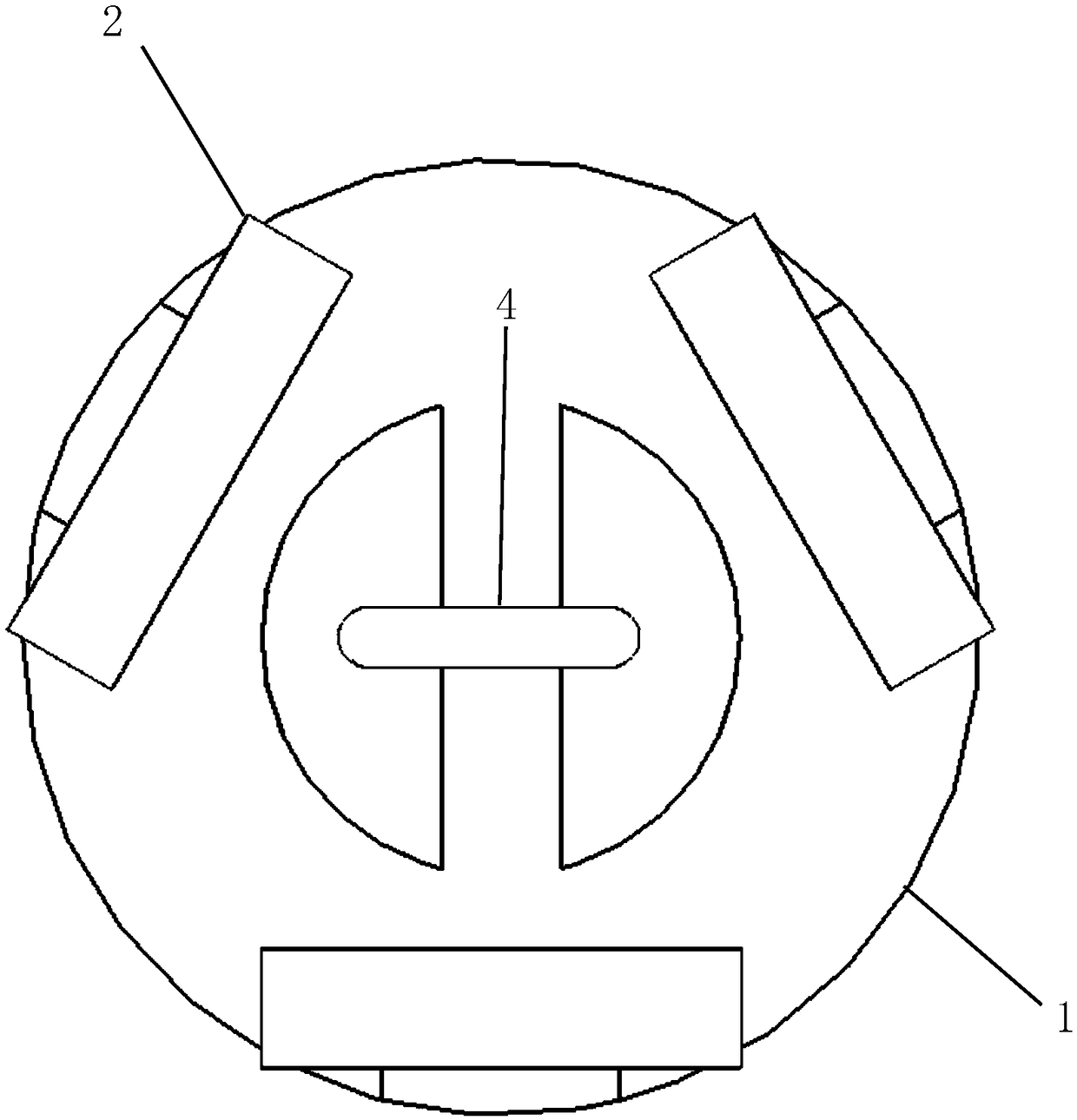

[0045] After the rough skin is removed by swaging the bar, the fixing parts and flaps are processed. After the processed fixing parts and flaps are polished with 400-800-2000 mesh sandpaper, they are polished in perchloric acid-absolute ethanol electrolytic polishing solution. The polished m...

Embodiment 2

[0049] The raw material of Example 1 is vacuum smelted in a vacuum smelting furnace to obtain a magnesium alloy with 0.45wt% Ca, 1.89wt% Zn and impurity content less than 0.01%. The obtained magnesium alloy is extruded into a Φ12mm rod after removing surface defects, and then swaged to obtain a Φ5.5mm rod. The measured mechanical properties of the magnesium-zinc-calcium bar material obtained in this embodiment are: yield strength ≥ 240 MPa, tensile strength ≥ 290 MPa, and elongation ≥ 15%. Its grain diameter is ≤10μm.

[0050] The swaged bar is ground and processed by the method in Example 1 to form a fixed piece and a flap, and then electropolished. Processing size: the size of the fixing piece is Φ4×4mm, the width of the beam of the fixing piece is 1mm; the width of the flap is 1mm, the length is 5mm, the thickness is 0.6mm, and the number is 5 pieces; the circumference of the fixing loop is 35mm (such as Figure 9 ). The total length of the prosthetic component prepared ...

Embodiment 3

[0054] The raw material of Example 1 is vacuum smelted in a vacuum smelting furnace to obtain a magnesium alloy with 0.29wt% Ca, 1.04wt% Zn and impurity content less than 0.01%. The obtained magnesium alloy is extruded into a Φ12mm rod after removing surface defects, and then swaged to obtain a Φ5.5mm rod. The measured mechanical properties of the magnesium-zinc-calcium bar material obtained in this embodiment are: yield strength ≥ 200 MPa, tensile strength ≥ 250 MPa, and elongation ≥ 25%. Its grain diameter is ≤10μm.

[0055] The swaged bar is ground and processed by the method in Example 1 to form a fixed piece and a flap, and then electropolished. Processing size: the size of the fixing piece is Φ5×4mm, the width of the beam of the fixing piece is 1.5mm; the widest part of the flap is 1.5mm, the length is 5mm, the thickness is 0.6mm, the shape is a long triangle, and the number is 6 pieces; the circumference of the fixing loop is 35mm ( Such as Figure 10 ). The total l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com