High efficiency pneumatic pipe bundle dedusting and defogging parallel device for N furnaces with one towerand application

A defogging device and high-efficiency technology, used in the fields of chemical industry and environmental protection, can solve the problems of undiscovered patent publications, harsh installation site requirements, and high wet power consumption, and achieve the effect of increasing the processing range, increasing the centrifugal effect, and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0046] Structures not described in detail in the present invention can be understood as conventional structures in the art.

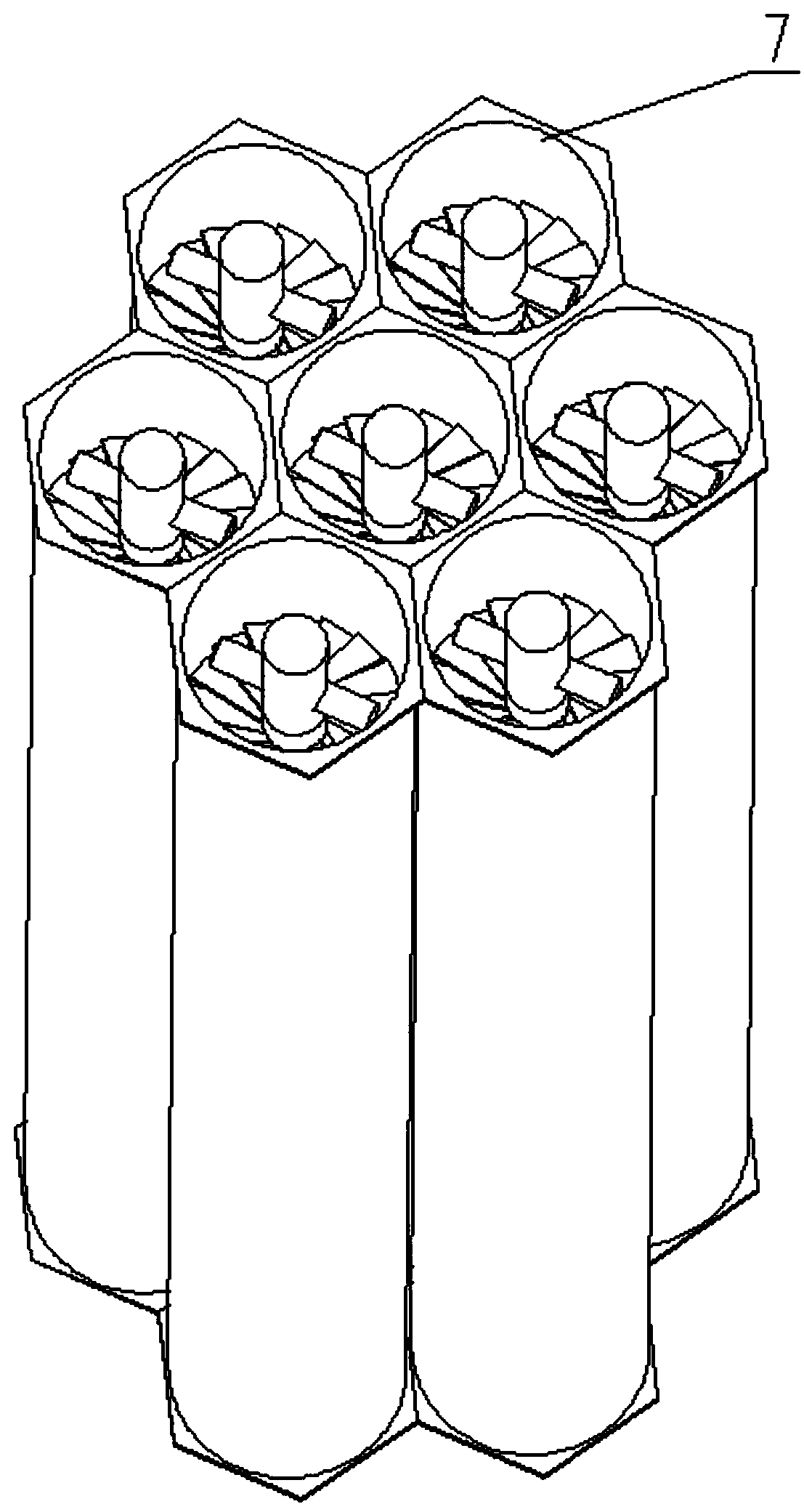

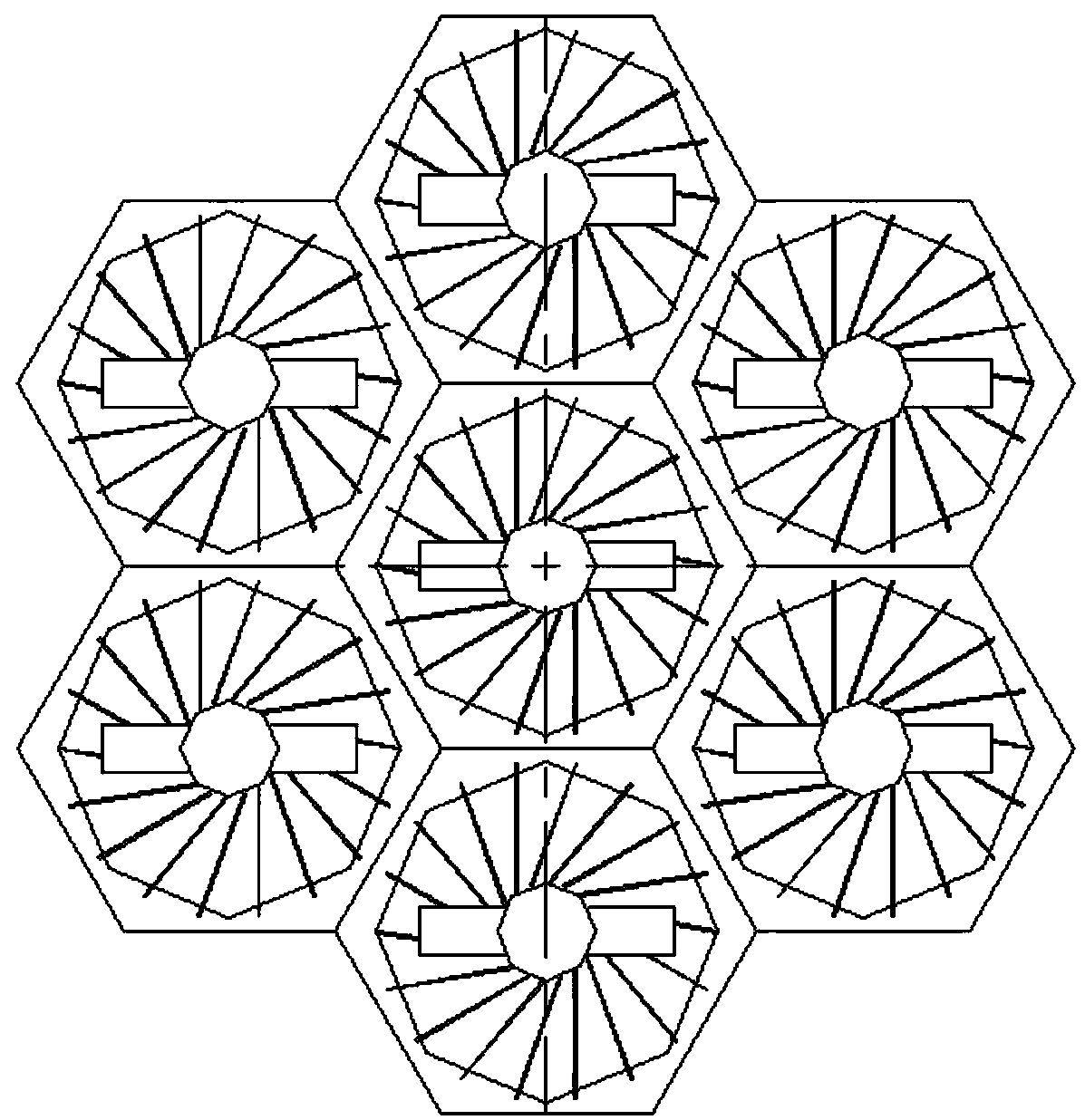

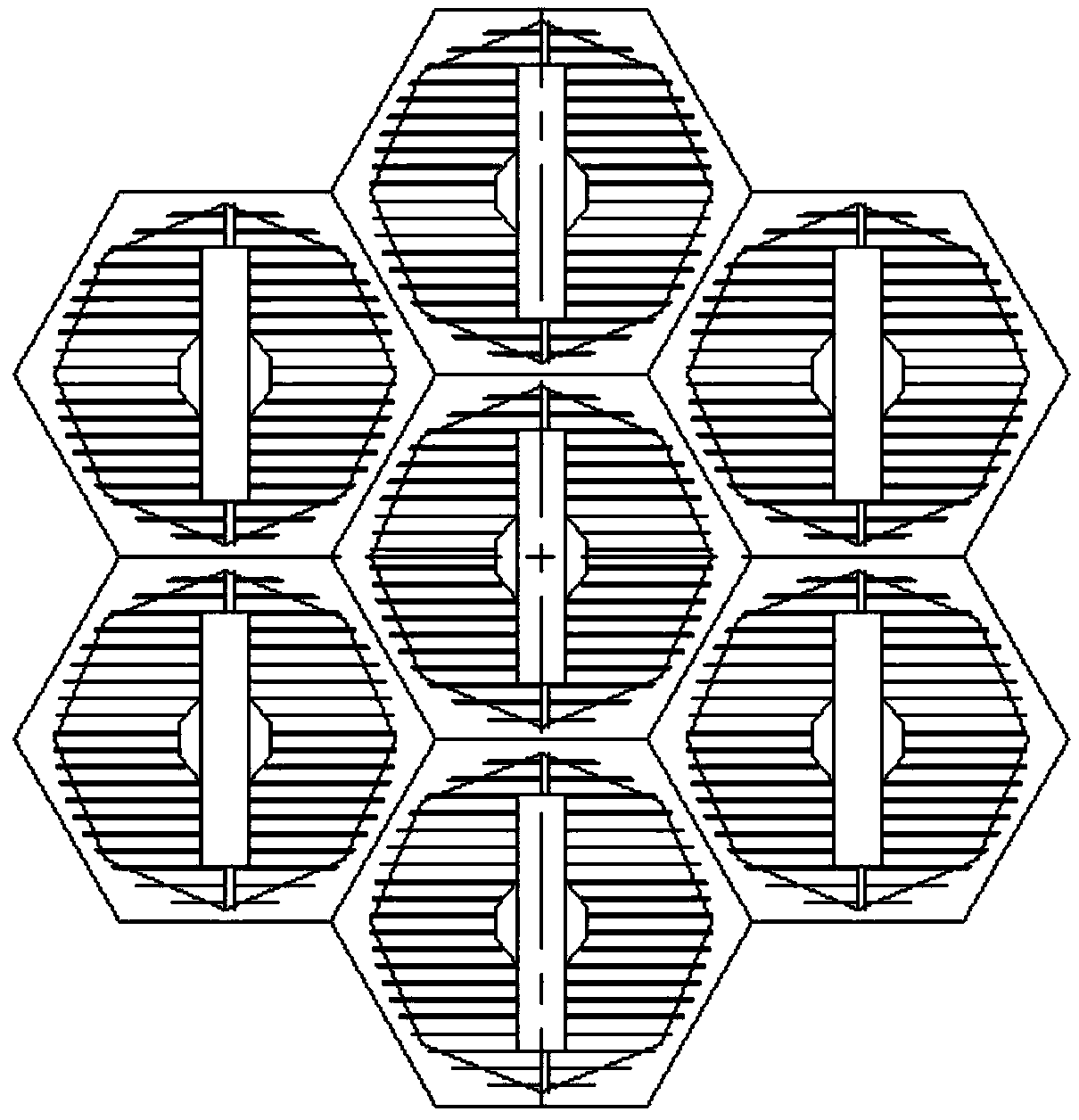

[0047] A kind of high-efficiency pneumatic tube bundle dedusting and demisting parallel device under the condition of N furnace and one tower, such as figure 1 , figure 2 and image 3 As shown, the device includes a plurality of high-efficiency pneumatic tube bundle dedusting and demisting parallel devices 7 connected in parallel. When in use, the high-efficiency pneumatic tube bundle dedusting and demisting parallel device can be sealed and connected with the inner wall of the exhaust gas treatment device.

[0048] In this embodiment, two adjacent high-efficiency pneumatic tube bundle dedusting and demisting paralle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com