Waste metal sorting-packaging system capable of compressing garbage, and sorting-packaging method

A technology for scrap metal and garbage, applied in combustion methods, garbage cleaning, garbage collection, etc., can solve the problems of inability to realize garbage trucks, single function, and no scrap metal compression, packaging and loading functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

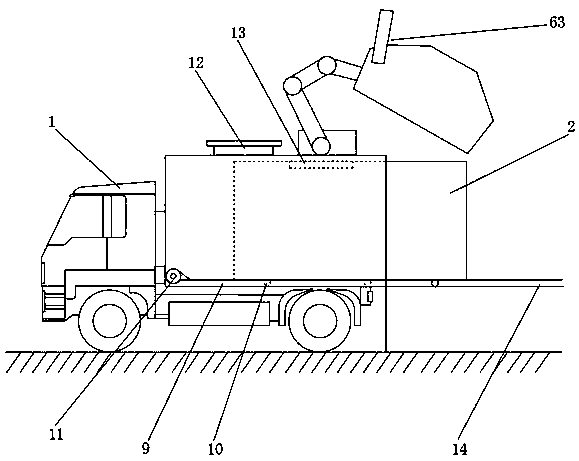

[0044] Embodiment 1: (no guide wheel 21; no return conveyor belt 60 and lifting baffle 61)

[0045] As shown in the accompanying drawings of the description, a scrap metal sorting and packaging system for compressible garbage includes a garbage recycling vehicle 1; it also includes a garbage truck inner tank 2, a dumping device 3, a breaking device 4, a shredding device 5, and non-ferrous metal Eddy current sorting machine 6, compression packaging equipment 7, loading device 8, liner cleaning and disinfection device 55 and control system; the inside of the compartment of the garbage recovery vehicle 1 is provided with an in-vehicle track 9; the interior tank of the garbage vehicle 2 The bottom of the bottom is provided with a pulley 10, and the top is provided with a garbage compression device 63; the inner tank 2 of the garbage truck is inserted into the compartment of the garbage recovery vehicle 1, and the pulley 10 is sleeved in the rail 9 in the car; the dumping device 3 ...

Embodiment 2

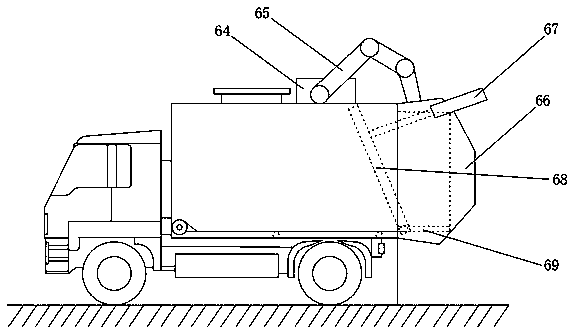

[0054] Embodiment 2: (with guide wheel 21; without return conveyor belt 60 and lifting baffle 61)

[0055] The second embodiment is basically the same in structure and principle as the first embodiment, except that the dumping device 3 also includes a guide wheel 21 . The traction cable 19 is connected to the inner container 2 of the garbage truck by bypassing two sets of guide wheels 21 . The guide wheel 21 plays a role in supporting and changing the direction of the traction rope 19 .

Embodiment 3

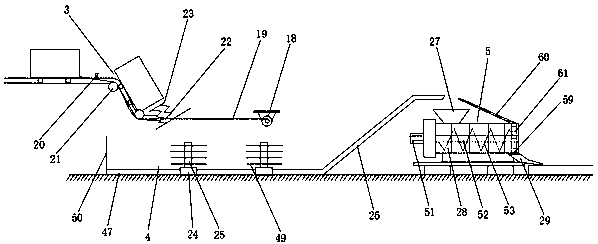

[0056] Embodiment 3: (without guide wheel 21; with return conveyor belt 60 and lifting baffle 61)

[0057] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, the difference is that said chopping device 5 also includes a return conveyor belt 60 and a lifting baffle 61; said return conveyor belt 60 is divided into a vertical lifting section and Inclined lifting section; the vertical lifting section is arranged in the chopping device 5 and passes upwards out of the chopping device 5; the inclined lifting section is arranged on the top of the chopping device 5, and one end is connected to the vertical lifting section, and the other end leads to the top of the feed hopper 27; the lifting baffle 61 is vertically distributed on the return conveyor belt 60. The rubbish whose size does not meet the requirements is brought back into the hopper by the return conveyor belt 60, and shredded again; the function of the lifting baffle 61 is to tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com