Spherical suspended bio-filler

A bio-filler, spherical technology, applied in the field of fillers, can solve the problems of not easy to hang the film, increase the cost of sewage treatment, small specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

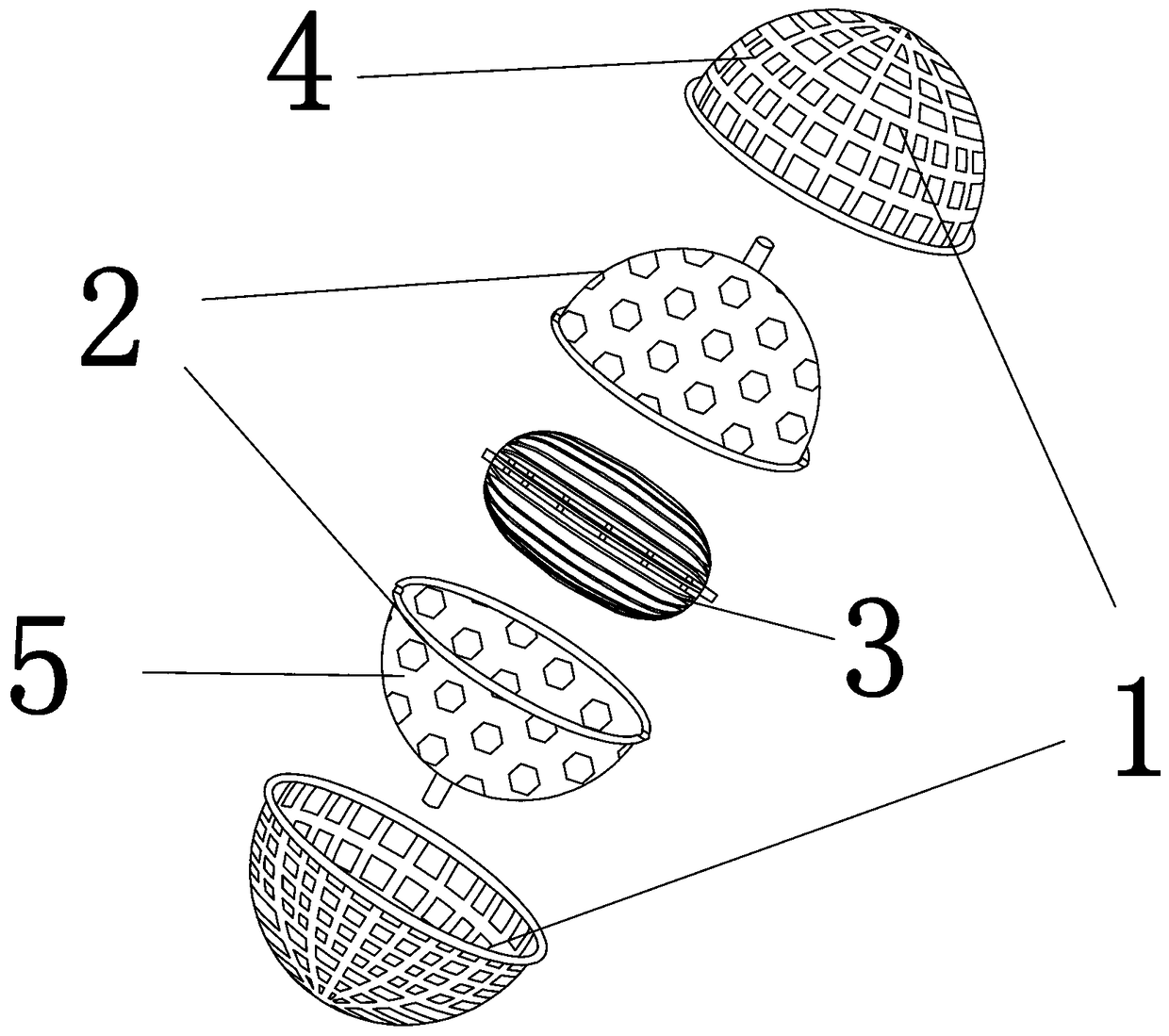

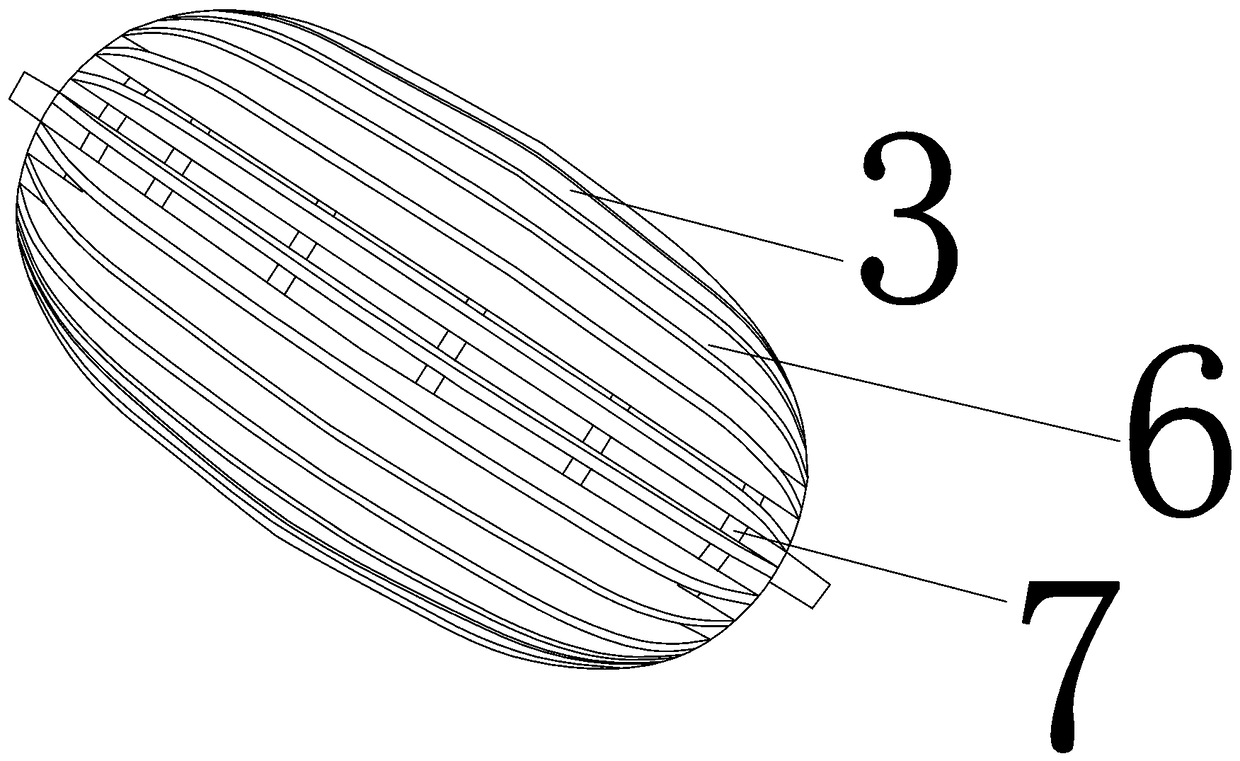

[0022] Such as Figure 1-Figure 2 As shown, a spherical suspended biological filler provided in this embodiment includes a spherical suspended biological filler, including a spherical shell 1, and a spherical body 2 that can rotate longitudinally is sleeved in the shell 1, and the The sphere 2 is sleeved with an ellipsoid 3 that can rotate laterally; the shell 1 is provided with hollow holes 4 , the sphere 2 is provided with hollow holes 5 , and the ellipsoid 3 is provided with fins. fins 6, and through grooves 7 are distributed between each fin 6.

[0023] The material of the shell 1, the spherical body 2 and the ellipsoid 3 is modified polypropylene.

[0024] The modified polypropylene is prepared by coating the surface of the polypropylene with a hydrophilic agent, and the hydrophilic agent includes 5 parts of nano silicon dioxide, 10 parts of alkylphenol polyoxyethylene ether, carbon nano 1 part of tube, 10 parts of polyvinyl chloride, 50 parts of ethanol, 10 parts of is...

Embodiment 2

[0028] The general structure of the spherical suspended biological filler provided in this embodiment is the same as that of the embodiment, the difference being that the material of the shell 1, the spherical body 2 and the ellipsoid 3 is modified polyethylene.

[0029] The modified polyethylene includes 95 parts of polyethylene and 5 parts of modifying agent by weight, and the modifier includes 50 parts of polyacrylate, 20 parts of polyethylene glycol, 10 parts of polyvinylidene fluoride, 5 parts of polyurethane, 2 parts of zirconium phosphate, and 1 part of rare earth.

[0030] The preparation method of the modifier is to put 50 parts of polyacrylate, 20 parts of polyethylene glycol, 10 parts of polyvinylidene fluoride, 5 parts of polyurethane, 2 parts of zirconium phosphate and 1 part of rare earth into 200-240 parts by weight. In a high-temperature reaction furnace at ℃, heat for 1-2 hours under the protection of nitrogen, and grind it into powder after cooling.

[0031]...

Embodiment 3

[0034] A spherical suspended biological filler provided in this embodiment has the same general structure as that of the embodiment, the difference being that the material of the shell 1 and the spherical body 2 is modified polypropylene, and the material of the ellipsoid 3 is modified polyethylene .

[0035] The modified polypropylene is prepared by coating the surface of the polypropylene with a hydrophilic agent, and the hydrophilic agent includes 10 parts by weight of nano silicon dioxide, 15 parts of alkylphenol polyoxyethylene ether, carbon nano 5 parts of tube, 15 parts of polyvinyl chloride, 60 parts of ethanol, 15 parts of isopropanol, and 40 parts of water.

[0036] The modified polyethylene includes 95 parts of polyethylene and 5 parts of modifying agent by weight, and the modifier includes 60 parts of polyacrylate, 30 parts of polyethylene glycol, 15 parts of polyvinylidene fluoride, 8 parts of polyurethane, 3 parts of zirconium phosphate, and 3 parts of rare eart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com