A kind of concrete material for 3D printing and preparation method

A technology for concrete and cementitious materials, applied in the fields of concrete materials, concrete composite materials, concrete components and their preparation, can solve the problems of poor overall performance of 3D printing products, low material performance, low bonding strength and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

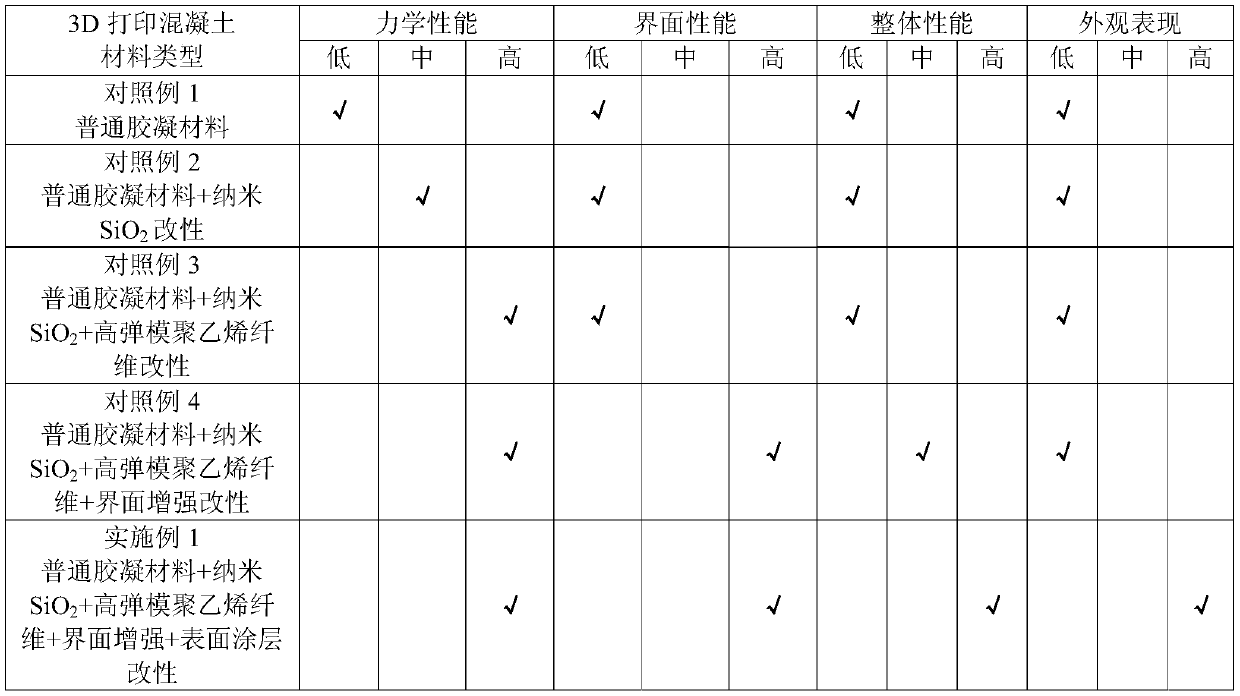

Examples

Embodiment 1

[0127] According to the formula ratio of concrete materials, measure 1.0 part of cementitious material, 2.0 parts of natural fine aggregate, 0.012 parts of nano silica, 0.025 parts of high elastic modulus polyethylene fiber, 0.01 part of redispersible latex powder, and 0.0005 part of lignocellulose. Mix for the first time for 2 minutes to obtain a ready-mix; measure 0.4 parts of water and 0.012 parts of thickening and water-reducing agent at the same time, stir and mix for 2 minutes to obtain a mixture; then add the mixture to the ready-mix Stir for the second time for 3 minutes to obtain the final mixture. The slump of the final mixture is 25mm, which is the concrete material sample 1# required for 3D printing. Among them, the cementitious material is a mixture of cement and fly ash, and the mass ratio of cement to fly ash is 1:1. The cement is selected from any of Portland cement or ordinary Portland cement, and the strength grade of the cement is 42.5. The classification of...

Embodiment 2

[0131] According to the formula ratio of concrete materials, measure 1.0 part of cementing material, 1.5 parts of natural fine aggregate, 0.015 parts of nano silica, 0.03 parts of high elastic modulus polyethylene fiber, 0.008 parts of redispersible latex powder, and 0.0008 parts of lignocellulose. Stir for the first time for 3 minutes to obtain a ready-mix; measure 0.5 parts of water and 0.009 parts of thickening and water-reducing agent at the same time and stir and mix for 3 minutes to obtain the mixture; then add the mixture to the ready-mix Stir for the second time for 2 minutes to obtain the final mixture. The slump of the final mixture is 30mm, which is the concrete material sample 2# required for 3D printing. Among them, the cementitious material is a mixture of cement and fly ash, and the mass ratio of cement to fly ash is 1:1.2. The cement is selected from any of Portland cement or ordinary Portland cement, and the strength grade of the cement is 42.5. The classifica...

Embodiment 3

[0135] According to the formula ratio of concrete materials, measure 1.0 part of cementitious material, 2.5 parts of natural fine aggregate, 0.01 part of nano silica, 0.02 part of high elastic modulus polyethylene fiber, 0.012 part of redispersible latex powder, and 0.001 part of lignocellulose. Mix for the first time for 1 minute to obtain a ready-mix; at the same time, measure 0.60 parts of water and 0.005 parts of thickening and water-reducing agent and stir and mix for 1 minute to obtain a mixture; then add the mixture to the ready-mix Perform the second mixing for 3 minutes to obtain the final mixture. The slump of the final mixture is 20mm, which is the concrete material sample 3# required for 3D printing. Among them, the cementitious material is a mixture of cement and fly ash, and the mass ratio of cement to fly ash is 1:0.8. The cement is selected from any of Portland cement or ordinary Portland cement, and the strength grade of the cement is 42.5. The classification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com