Sodium myristate crystal form and preparation method thereof

A technology of sodium myristate and crystal form, applied in the field of sodium myristate crystal form and preparation thereof, can solve the problems of cumbersome post-processing and drying, difficult product purification and the like, and achieves easy large-scale preparation, good chemical stability, Solve the effect of solvent wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

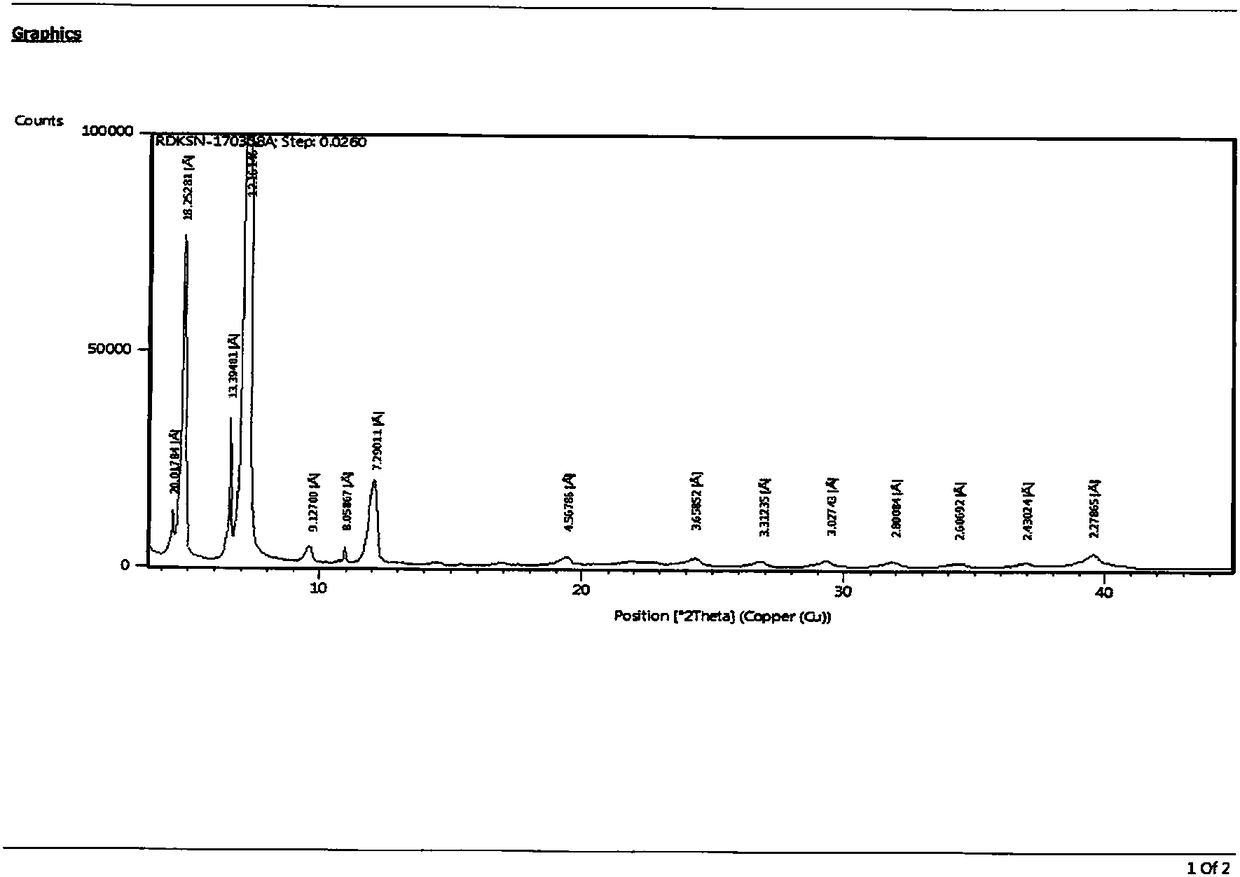

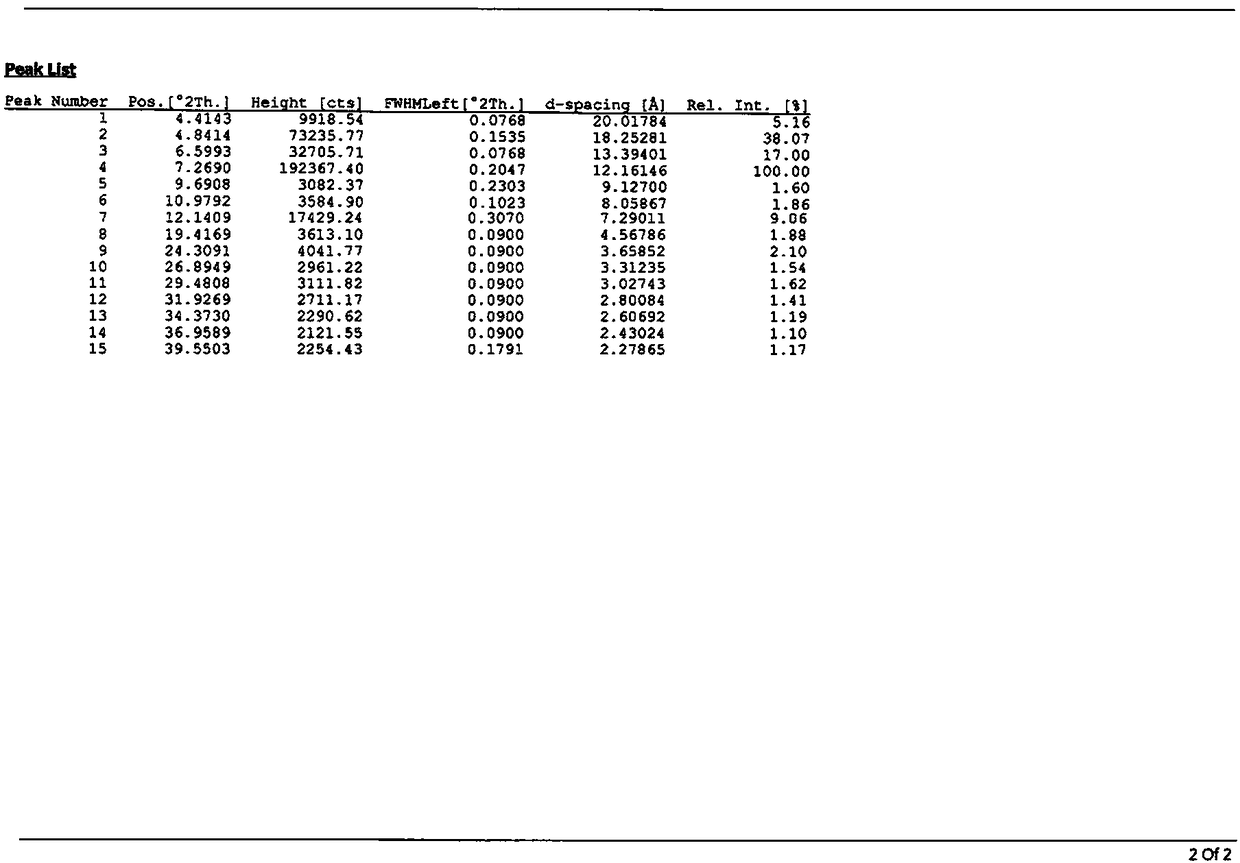

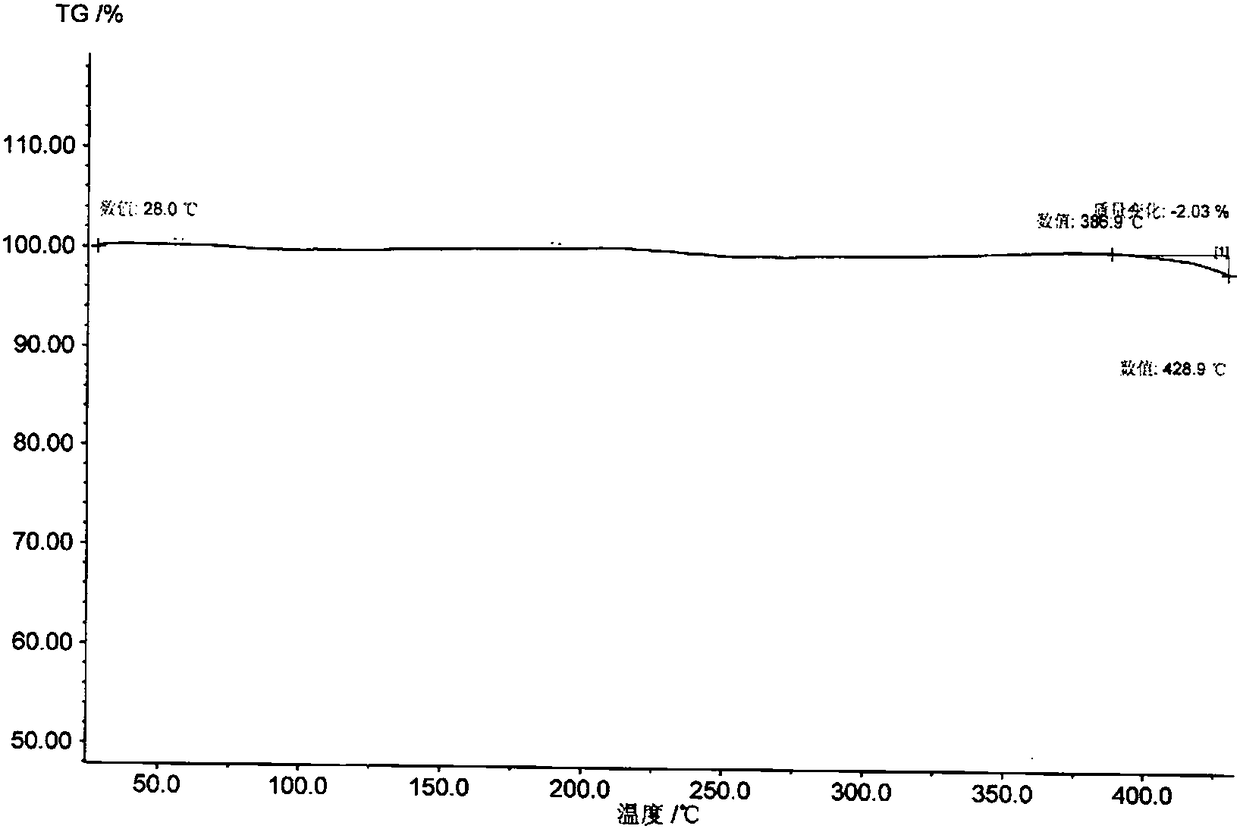

Image

Examples

Embodiment 1

[0019] Example 1: Add 5g of sodium myristate and 20ml of purified water to a 250ml reaction bottle equipped with a reflux device, heat up to 80°C, add 30ml of ethyl acetate, stir, pour the reaction solution into a 250ml beaker, and let it cool naturally 0.5h, then cool down to 5°C in an ice-water bath, stand for crystallization for 1h, collect the filter cake by suction filtration, and dry for 12h to obtain a needle-like solid in the crystal form of sodium myristate with a yield of 94.0% and a purity of 99.96%.

Embodiment 2

[0020] Example 2: Add 5g of sodium myristate and 25ml of purified water to a 250ml reaction bottle equipped with a reflux device, heat up to 70°C, add 30ml of ethyl acetate, stir, pour the reaction solution into a 250ml beaker, and let it cool naturally 0.5h, then cool down to 0°C in an ice-water bath, stand for crystallization for 1h, collect the filter cake by suction filtration, and dry for 12h to obtain a needle-like solid in the crystal form of sodium myristate, with a yield of 95.3% and a purity of 99.93%.

Embodiment 3

[0021] Example 3: Add 5g of sodium myristate and 10ml of ethanol to a 250ml reaction flask equipped with a reflux device, heat up to 80°C, add 20ml of ethyl acetate, stir, pour the reaction solution into a 250ml beaker, and let it cool naturally for 0.5 h, then cooled to 3°C in an ice-water bath, left to stand for crystallization for 1 h, collected the filter cake by suction filtration, and dried for 12 h to obtain a needle-like solid in the crystal form of sodium myristate with a yield of 94.6% and a purity of 99.91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com