Method for recovering organic tin from organic tin distillation waste

A technology of organotin and organic materials, applied in the fields of organic chemistry, tin-organic compounds, chemical instruments and methods, etc., can solve the problems of not effectively guaranteeing the accuracy of heating temperature, harm to the environment and health of staff, waste of raw materials, etc. Improve economic efficiency and environmental protection concept, simple and feasible operation, and avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

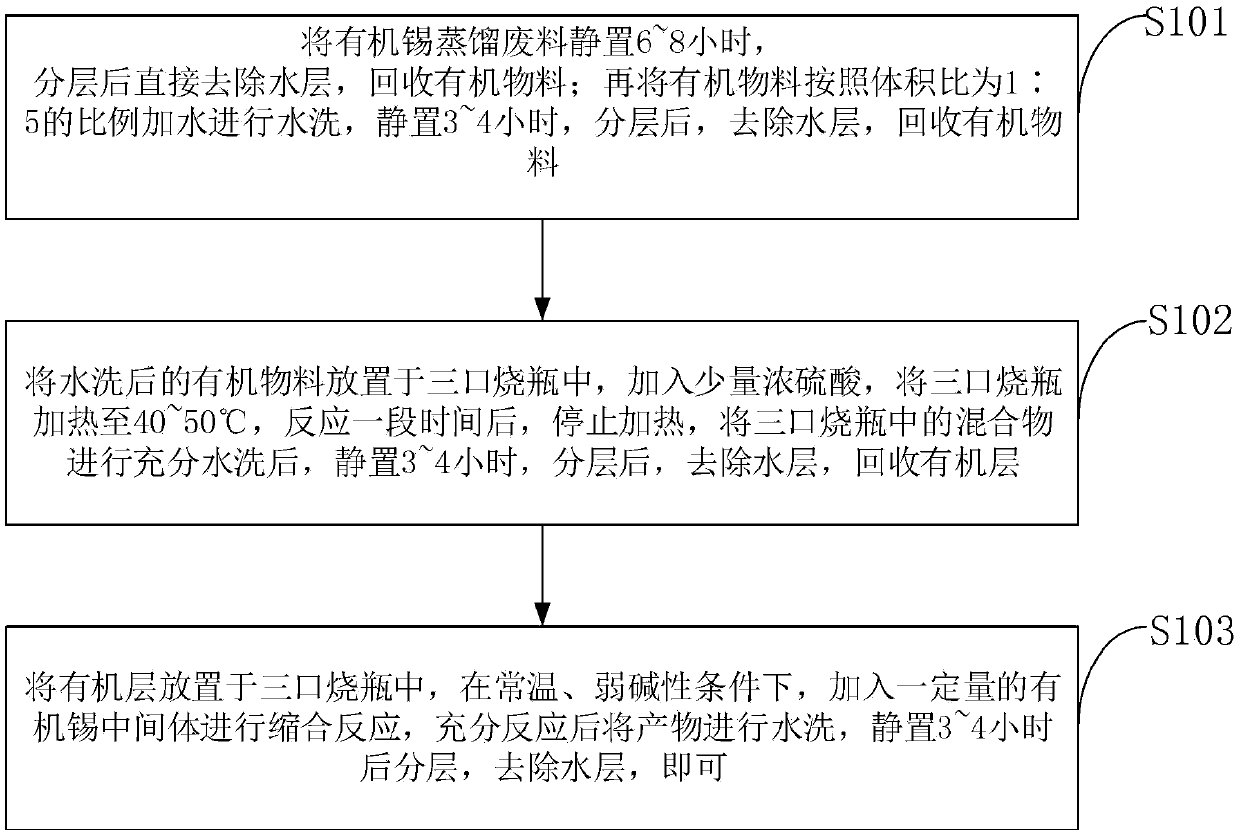

[0146] A method of reclaiming organotin from organotin distillation waste is:

[0147] Step 1: Put the distillation waste of isooctyl tin dimethyl dimercaptoacetate to stand for 6 hours, remove the water layer directly after layering, and recycle the organic material; then add water to the organic material according to the volume ratio of 1:5 for washing , stand still for 3 hours, after stratification, remove the water layer, and recycle the organic material;

[0148] Step 2: Place the washed distillation waste of isooctyl tin dimethyldithioglycolate in a three-necked flask, add a small amount of concentrated sulfuric acid, and heat the three-necked flask to 40°C. After a period of reaction, stop heating, and place the three-necked flask After the mixture in is fully washed with water, let it stand for 3 hours, after layering, remove the water layer, and recover the organic layer;

[0149] Step 3: Condensation reaction: Place the organic layer in a three-necked flask, add a c...

Embodiment 2

[0151] A method of reclaiming organotin from organotin distillation waste is:

[0152] Step 1: Put the distillation waste of isooctyl tin dimethyl dimercaptoacetate to stand for 7 hours, remove the water layer directly after layering, and recycle the organic material; then add water to the organic material according to the volume ratio of 1:5 for washing , stand still for 3.5 hours, after stratification, remove the water layer, and recycle the organic material;

[0153] Step 2: Place the washed distillation waste of isooctyl tin dimethyldithioglycolate in a three-necked flask, add a small amount of concentrated sulfuric acid, and heat the three-necked flask to 45°C. After a period of reaction, stop heating, and place the three-necked flask After the mixture in was fully washed with water, it was left to stand for 3.5 hours. After the layers were separated, the water layer was removed and the organic layer was recovered;

[0154] Step 3: Condensation reaction: Place the organi...

Embodiment 3

[0156] A method of reclaiming organotin from organotin distillation waste is:

[0157] Step 1: Put the distillation waste of isooctyl tin dimethyl dimercaptoacetate to stand for 8 hours, remove the water layer directly after layering, and recycle the organic material; then add water to the organic material according to the volume ratio of 1:5 for washing , stand still for 4 hours, after stratification, remove the water layer, and recycle the organic material;

[0158] Step 2: Place the distillation waste of isooctyl tin dimethyl dimercaptoacetate after washing in water into a three-necked flask, add a small amount of concentrated sulfuric acid, and heat the three-necked flask to 50°C. After a period of reaction, stop heating, and put the three-necked flask After the mixture in is fully washed with water, let it stand for 4 hours, after layering, remove the water layer, and recover the organic layer;

[0159]Step 3: Condensation reaction: Place the organic layer in a three-nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com