Attapulgite-based polymer material additive as well as preparation method thereof and application thereof in preparation of flame-retardant polymer materials

A technology of polymer materials and flame-retardant polymers, applied in the field of flame-retardant materials, can solve the problems of composite materials such as new energy decline and sacrifice performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

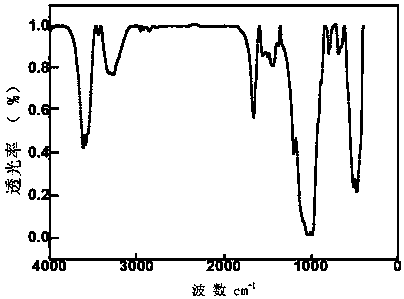

Image

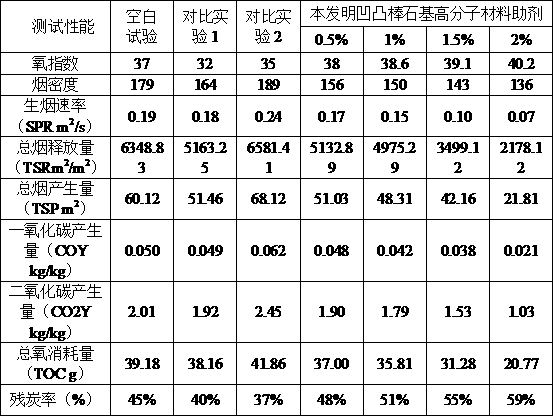

Examples

preparation example Construction

[0025] (1) The preparation process of attapulgite-based polymer additives is as follows:

[0026] Activation of attapulgite: Add attapulgite powder into 10wt% sodium hydroxide solution, prepare a slurry with a concentration of 15wt%~35wt%, stir and react at 80~100°C for 5~10h, then centrifuge and wash until Neutral, dry at 100-150°C for 5 hours, and crush to more than 2000 mesh.

[0027] Modification: add activated attapulgite powder into absolute ethanol, control the mass concentration at 15% to 35%, and add dibutyltin diacetate with a mass fraction of attapulgite powder of 1 to 20%, 60 to Stir the reaction at 100°C for 1-5 hours, and then centrifuge.

[0028] Purification: Soxhlet extraction of the centrifuged product with acetone, dichloromethane, and chloroform for 10-15 hours, and finally vacuum-drying at 100-120°C for 10-15 hours, airflow crushing to more than 2500 mesh to obtain attapulgite Additives for polymer-based materials.

[0029] The attapulgite-based polymer...

Embodiment 1

[0038] Add attapulgite powder into 10wt% sodium hydroxide solution, prepare a slurry with a concentration of 15wt%, stir and react at 80°C for 10h, then centrifugally wash until neutral, dry at 100-150°C for 5h, and pulverize To more than 2000 mesh. The powder was added to absolute ethanol, the mass concentration was controlled at 15% to 35%, and dibutyltin diacetate with a mass fraction of attapulgite powder of 1% was added, stirred and reacted at 60°C for 5 h, and then centrifuged. The centrifuged product is sequentially extracted with acetone, dichloromethane, and chloroform for 10-15 hours, and finally vacuum-dried at 100-120°C for 10-15 hours, and air-jet crushed to a size above 2500 mesh to obtain attapulgite-based high Additives for molecular materials.

Embodiment 2

[0040] Add attapulgite powder into 10wt% sodium hydroxide solution, prepare a slurry with a concentration of 20wt%, stir and react at 90°C for 8h, then centrifugally wash until neutral, dry at 100-150°C for 5h, and pulverize To more than 2000 mesh. The powder was added to absolute ethanol, the mass concentration was controlled at 15% to 35%, and dibutyltin diacetate with a mass fraction of attapulgite powder of 5% was added, stirred and reacted at 70°C for 4 h, and then centrifuged. The centrifuged product is sequentially extracted with acetone, dichloromethane, and chloroform for 10-15 hours, and finally vacuum-dried at 100-120°C for 10-15 hours, and air-jet crushed to a size above 2500 mesh to obtain attapulgite-based high Additives for molecular materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com