400MP class a seismic chloride-corrosion-resistant reinforcing steel bar and manufacturing method thereof

A technology of ion corrosion and manufacturing method, applied in the field of metallurgy, can solve the problems of corrosion, reduce the durability of the structure, change the stress state of the structure, etc., and achieve the effect of good corrosion resistance, improved strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

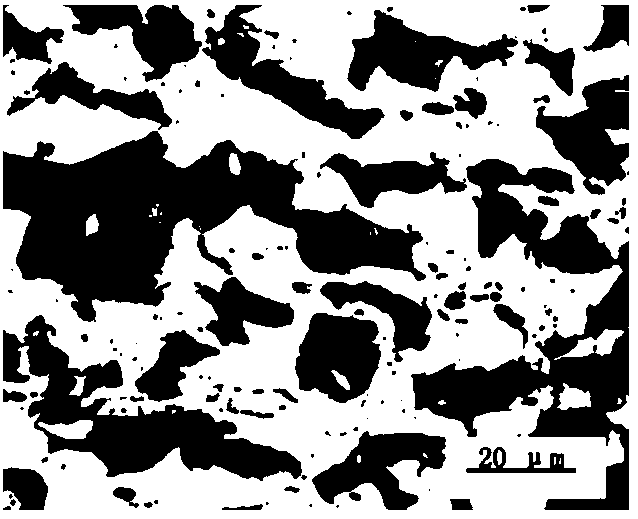

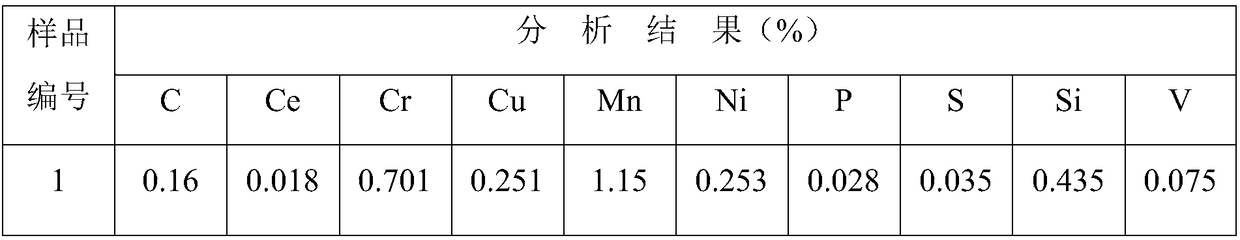

Embodiment 1

[0023]The chemical composition of the 400MPa grade earthquake-resistant chloride ion corrosion-resistant steel bars in this example is shown in Table 1. The main preparation process of the steel bar is: molten iron desulfurization-converter-LF refining-continuous casting-rolling. Hot metal desulfurization: Remove blast furnace slag before desulfurization to improve desulfurization efficiency; take iron ore and melt it into molten iron, and the molten iron is desulfurized by KR method. Lime powder and fluorite mixed with a desulfurizer at a mass ratio of 9:1, stirred for 10 minutes, and left to stand for 5 minutes. Remove the desulfurization slag after the molten iron is desulfurized to stabilize the desulfurization effect, prevent the desulfurization slag from entering the converter and cause the converter to return to sulfur, and ensure that the sulfur content in the steel is controlled below 0.01%. Converter: Decarburization and dephosphorization are carried out by top-bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com