An electrospinning device and electrospinning method for realizing carbon material nitrogen doping

An electrospinning, carbon material technology, used in textiles and papermaking, filament/thread forming, non-woven fabrics, etc., can solve problems such as performance needs to be improved, achieve excellent structure and performance, increase nitrogen content, and excellent pores effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

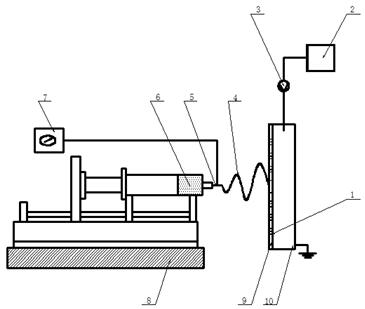

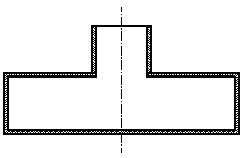

[0020] This embodiment realizes the electrospinning device of carbon material nitrogen doping, such as figure 1 As shown, it includes a micro liquid supply pump 8 and a power supply device 7, and a liquid supply device 6 communicated with the micro liquid supply pump 8 is provided above the micro liquid supply pump 8. The needle point 5 of the liquid supply device 6 and the power supply device 7 and the direct current The high-voltage positive electrode is connected, and a receiving device connected to the DC high-voltage negative electrode is placed at a distance of 10-20 cm from the needle point 5 of the liquid supply device 6 in the vertical direction. The receiving device includes a receiving gas collecting plate 10, and a heating element is installed inside the receiving gas collecting plate 10; Several exhaust holes are distributed on the upper surface of the receiving gas collecting plate 10 , and the receiving gas collecting plate 10 is fixed with a receiving foil 9 , a...

Embodiment 2

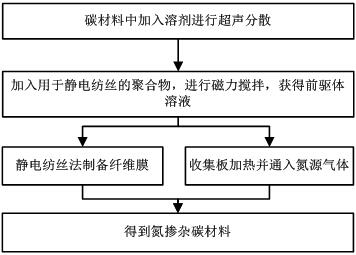

[0025] This embodiment realizes the electrospinning method of carbon material nitrogen-doped electrospinning device, such as image 3 shown, including the following steps:

[0026] (1) Add 9 g of dimethylformamide to 0.02 g of graphite oxide, and ultrasonically disperse for 45 minutes to obtain a gray-black suspension.

[0027] (2) Add 0.7 g of polyacrylonitrile to the suspension, place it on a magnetic stirrer and continue to stir for 2 hours while keeping the temperature at 60° C. until all of the solution dissolves and turns into a black sol to obtain a spinning precursor solution.

[0028] (3) Attach the aluminum foil to the receiving device and connect the DC high-voltage negative electrode to heat the receiving gas collecting plate to 600°C, and continuously blow in nitrogen gas.

[0029] (4) Place the liquid supply device 6 with the precursor solution on the positive electrode position, keep the distance from the receiving gas collecting plate 10 at 17cm, the voltage i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com