A functional interlayer of lithium-sulfur battery and preparation method thereof

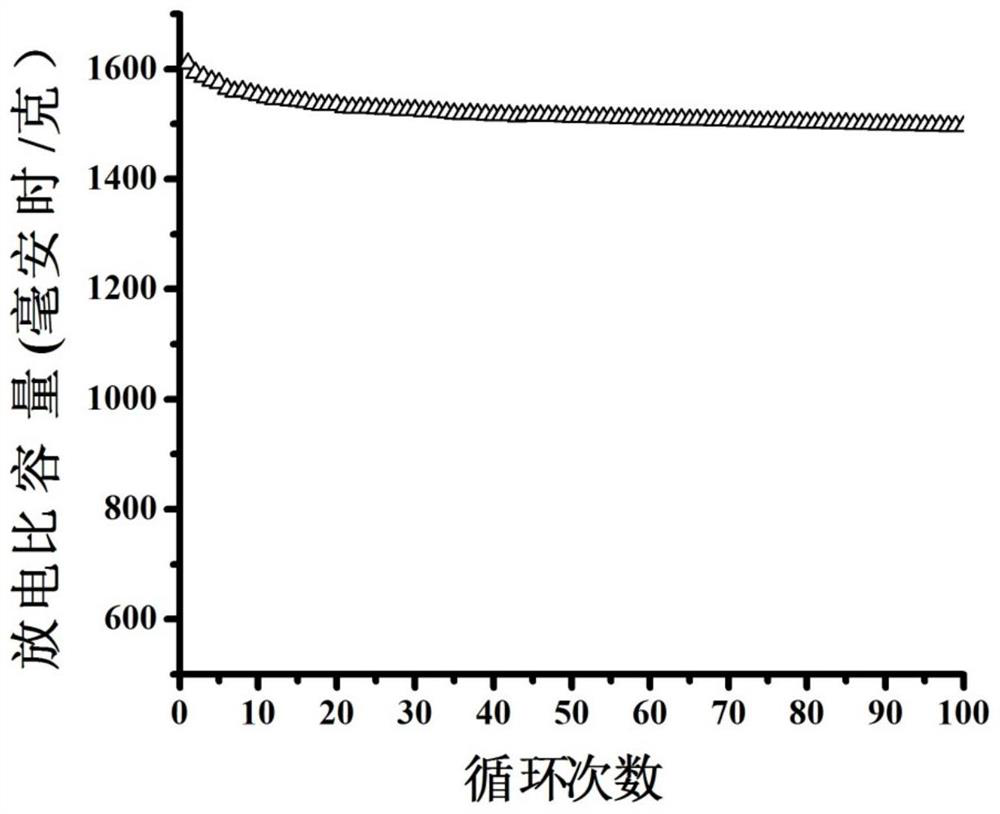

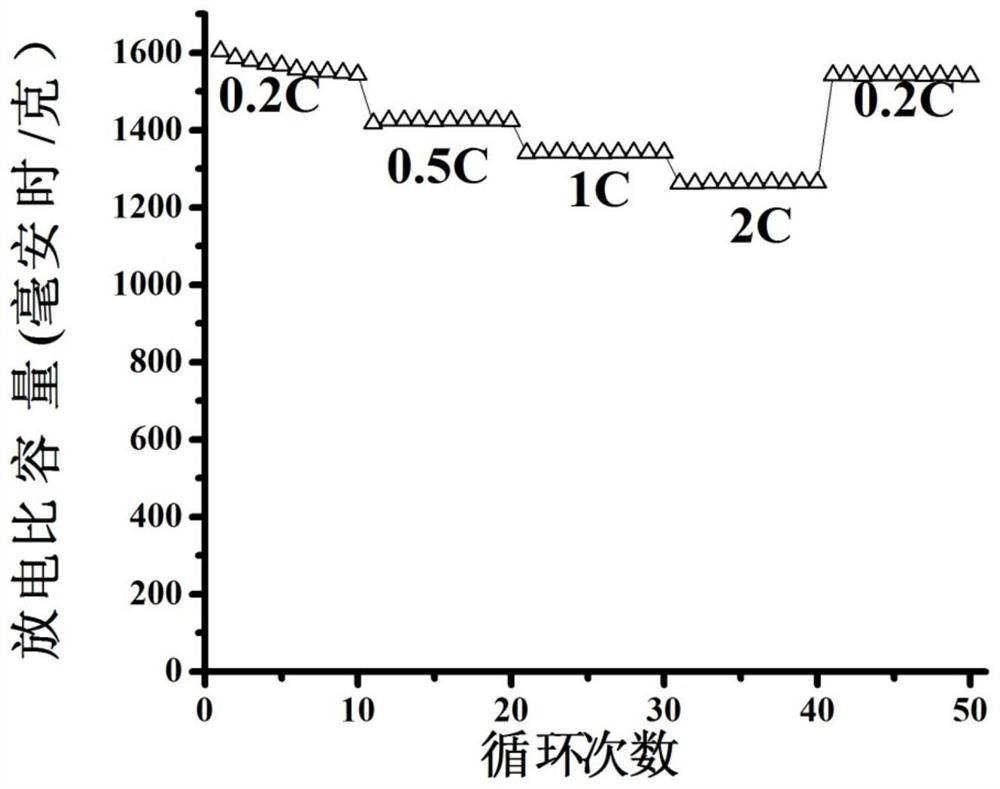

A lithium-sulfur battery, functional technology, applied in the field of material chemistry, can solve the problems of undesignable molecular structure and unadjustable chemical function, etc., achieve effective and stable temperature control, improve cycle stability, and obvious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

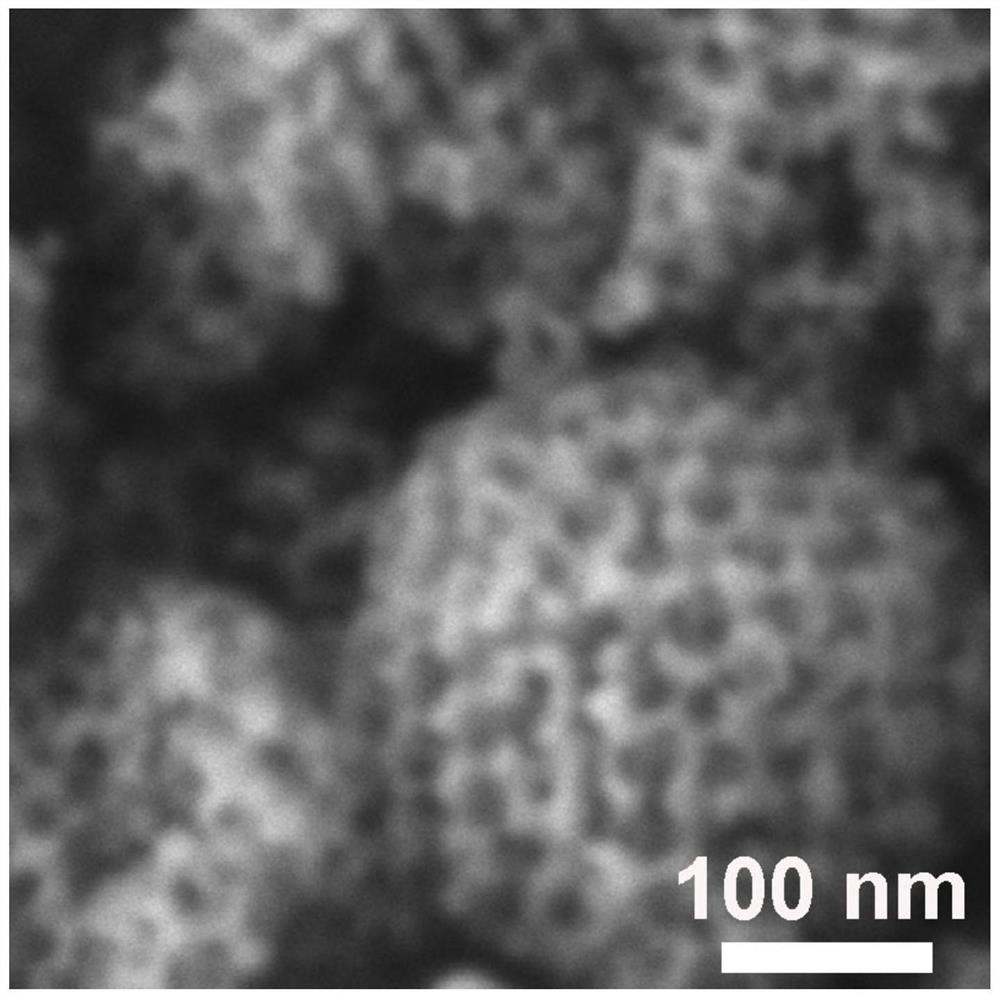

[0027] (1) Preparation of polyurea porous material:

[0028] Take 40 mL of acetone and 40 mL of deionized water, mix them evenly, add 15 mL of toluene diisocyanate dropwise to it under stirring, and the drop rate is 0.2 mL / s. After completion, centrifuge, wash, and dry to obtain a powdered polyurea porous material.

[0029] (2) Carbonized polyurea porous material:

[0030] The polyurea porous material prepared in step (1) was placed in a tube furnace, heated to 600 °C at a rate of 3 °C / min in an argon atmosphere, kept for 2 hours, and then cooled with the furnace still in an argon atmosphere, The carbonized polyurea porous material powder was obtained.

[0031] (3) Preparation of functional separator:

[0032] The carbonized polyurea porous material prepared in the step (2), the conductive agent super p, and the binder polyvinylidene fluoride are proportioned in a mass ratio of 8:1:1, and ground with a mortar for 2 hours to uniformly disperse, and then add The 1-methyl-2-p...

Embodiment 2

[0036] (1) Preparation of polyurea porous material:

[0037] Take 50 mL of acetone and 50 mL of deionized water, mix them evenly, add 20 mL of toluene diisocyanate dropwise to it under stirring, and the drop rate is 0.3 mL / s. After completion, centrifuge, wash, and dry to obtain a powdered polyurea porous material.

[0038] (2) Carbonized polyurea porous material:

[0039] The polyurea porous material prepared in step (1) was placed in a tube furnace, heated to 500 °C at a rate of 1 °C / min in an argon atmosphere, kept for 1 h, and then cooled with the furnace still in an argon atmosphere, The carbonized polyurea porous material powder was obtained.

[0040] (3) Preparation of functional separator:

[0041]The carbonized polyurea porous material prepared in the step (2), the conductive agent super p and the binder polyvinylidene fluoride are proportioned in a mass ratio of 8:1:1, and ground for 2 hours with a mortar to uniform dispersion, and then added. The 1-methyl-2-pyrr...

Embodiment 3

[0043] (1) Preparation of polyurea porous material:

[0044] Take 30 mL of acetone and 30 mL of deionized water, mix them evenly, and add 10 mL of toluene diisocyanate dropwise to it under stirring conditions. After completion, centrifuge, wash, and dry to obtain a powdered polyurea porous material.

[0045] (2) Carbonized polyurea porous material:

[0046] The polyurea porous material prepared in step (1) was placed in a tube furnace, heated to 800 °C at a rate of 5 °C / min in an argon atmosphere, kept for 3 hours, and then cooled with the furnace still in an argon atmosphere, The carbonized polyurea porous material powder was obtained.

[0047] (3) Preparation of functional separator:

[0048] The carbonized polyurea porous material prepared in the step (2), the conductive agent super p and the binder polyvinylidene fluoride are mixed in a mass ratio of 8: 1: 1, and the mortar is used for grinding for 1 hour until the dispersion is uniform, and then added. 1-Methyl-2-pyrr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com